Macro Sensors Gauge Tank Volume Changes

Configured with a float, Macro Sensors HSIR Series LVDT Linear Position Transmitters are serving as level sensors to measure liquid level changes from a few inches to several feet in gauging tank level volumes.

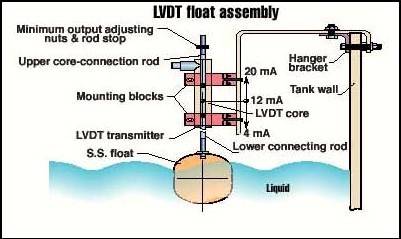

In this LVDT level sensor configuration, a stainless-steel float coupled to a nonmagnetic stainless-steel rod is attached to the high-permeability, armature core of the LVDT. The 4 to 20-mA loop-powered LVDT position transmitter senses the position of the core and, therefore, the level of the float. Sensitivity to the change in level depends on the length of LVDT. While LVDT level sensors are used to measure level changes from 0 to 2, 12, or 20 in. (50, 300, or 500 mm), shorter lengths offer greatest sensitivity.

In operation, as water level changes, the float moves up or down, raising the LVDT core along with it. A threaded stainless-steel rod, that protrudes from the other end of the core, carries two jam nuts that are used to adjust the position sensor output at the desired low water level. The nuts also prevent the core from falling out of the LVDT housing if the liquid level drops too low. A nonmagnetic clamp block attaches the stainless-steel body of the LVDT to a flat hook. The hook hangs the level-sensor assembly over the tank edge.

Core position is sensed using magnetic induction. Electronics of the LVDT are hermetically sealed inside a stainless-steel housing for protection against water and other environmental elements. A Teflon liner inside the bore minimizes any friction to core motion. As there are no springs to fatigue or parts to wear out, the LVDT Linear Position Sensors are nearly friction free to offer infinite resolution and long term operation.

macrosensors.com