Americas Cup Innovation & a Carbon-Free Shipping Future

The Golden Gate Yacht Club (GGYC) represented by BMW Oracle Racing and the Société Nautique de Genève (SNG), the Americas Cup defending champion, represented by Team Alinghi were entwined in a 2.5-year legal battle over multiple court cases, including hearings in the New York Supreme Court and the Appellate Division of the New York Supreme Court, prior to the 33rd edition of the race, due to take place in 2010.The parties disagreed about the location, format, and restrictions on boat design, all of which were changed by the courts prior to the race.

Keep It Steady

Gothenberg, Sweden based Humphree was founded in 2002 by a team of engineers that sought to leverage their expertise in high-speed marine propulsion – or more specifically, hydrodynamics, electronics and digital controls – to create vessel stabilization packages that would be easy to install and use. And thus, Humphree’s interceptors were created.The compact and robust transom-mounted units feature an adjustable blade that activates vertically into the water stream beneath the hull to create a lift force.

Goldwind Wins Certification LiDAR Tech

Chinese wind turbine manufacturer Goldwind is the world’s first OEM to receive DNV GL’s Component Certification for its LiDAR Assisted Control system.The certificate is issued according to DNV GL’s own Type and Component Certification Service Specification in conjunction with the Recommended Practice for new Technology Qualification.LiDAR, which stands for “Light Detection And Ranging”, is a technique where a laser source is used to sense the incoming wind field in front of a wind turbine rotor. Its application to wind turbine control systems facilitates the reduction of loads on certain components such as the tower and blades, improves…

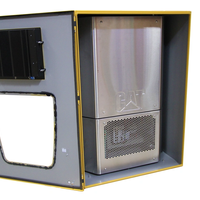

CAT Targets Cruise for MEO, AI

Caterpillar is touting its Multi-Engine Optimizer (MEO) as a solution for existing cruise ships to burn less fuel, run cleaner, keep uptime and reliability high while keeping costs down.Caterpillar's MEO is designed to lay over the top of a vessel’s existing power management system, us-ing proprietary performance maps and control algorithms to advise the system on which engines to operate and at what load. The second, Asset Intelligence (AI), is a total vessel monitoring solution that collects and analyzes data from onboard systems, then provides recommendations on when and how to take action.

Humphree: Steady as She Goes

Humphree makes inroads in North American markets with vessel stabilization technology.If you haven’t yet heard of Humphree – the Sweden-based supplier of vessel stabilization systems – then, more than likely, that’s about to change. The firm’s penetration into the North American commercial and leisure marine market has seen its equipment on several vessels, including high-profile deployments like the new Seastreak high-speed commuting ferry.Founded in 2002 by a team of hydrodynamic and marine engineers…

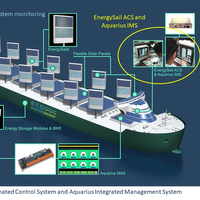

Automation for Ship Renewable Energy Systems Unveiled

As part of the ongoing strategy to prepare its EnergySail and Aquarius MRE for commercial release, Eco Marine Power (EMP) unveiled further details of its automated control and monitoring systems. These will enable EMP’s technologies to integrate with existing ship-based systems. This will facilitate the seamless operation between EMP's renewable energy platforms with other equipment on ships including fuel flow meters.Three marine computer systems jointly developed with KEI System Ltd will be integrated to provide a robust…

Technology Qualification on the Route to Autonomy

ABS weighs in on the way forward for marine autonomous systems and navigation technology. The era of digitization and hyper-connectivity is taking the maritime industry on a journey as it transitions from ‘smart’ to remotely operated and then, to autonomous vessels. The OSV sector – and offshore workboats in general – may well be leading that transition, with some projections for remote-controlled vessels as soon as next year. Many new technologies (sensors, navigational systems…

Eco Marine Power to Use Artificial Intelligence

To further enhance its research capabilities Eco Marine Power announced today that it will begin using the Neural Network Console provided by Sony Network Communications Inc., as part of a strategy to incorporate Artificial Intelligence (AI) into various ongoing ship related technology projects including the further development of the patented Aquarius MRE (Marine Renewable Energy) and EnergySail. The Neural Network Console is an integrated development environment using deep learning for AI creation and has been used in deep learning applied technology development within Sony since 2015. Various functions are included such as recognition technology and a full-fledged GUI (graphical user interface) and these allow for deep learning programs to be developed.

Caterpillar Launches Multi-Engine Optimizer Tool

Caterpillar Marine has unveiled its new Multi-Engine Optimizer (MEO) tool, which leverages proprietary performance data and patented control algorithms to provide intelligence for power management systems. MEO works by advising power management systems on which engines to operate and enables the use of dynamic asymmetric loads to drive the combination of engines and loads to create the lowest possible fuel consumption. “MEO is designed to operate in conjunction with any system, new or retrofit,” said Theodore Wiersema, business process manager for Caterpillar Marine.

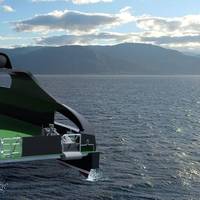

World First: Unmanned Autonomous Boat for Offshore Ops

While talk of autonomous operations in the maritime sector have swirled for years, the talk becomes reality as Automated Ships Ltd. (an M Subs Ltd subsidiary) and Norway’s Kongsberg Maritime signed a Memorandum of Understanding to build the world’s first unmanned and fully-automated vessel for offshore operations. In January 2017, Automated Ships Ltd will contract the ‘Hrönn’, which will be designed and built in Norway in cooperation with KONGSBERG. Sea trials will take place…

Student Challenge: Control Airship Using Offshore DP Technology

KONGSBERG has introduced a new student project called 'Zeppaloon' which provides students with the opportunity to resolve a complex technological task during the summer months of 2014. The assignment for the 'Zeppaloon' project is to develop a scaled unmanned airship to simulate the dynamic positioning technology that KONGSBERG uses to operate offshore vessels in challenging conditions. The challenge involves developing a prototype with sub systems such as; software, sensors and reference systems, thruster and power management and control algorithms.

Aker Arctic & Navis Engineering Agree DP Collaboration

Aker Arctic Technology Inc and Navis Engineering Oy have signed an agreement on joint development of Dynamic Positioning systems for ice operation. The companies plan to jointly develop next-generation DP-system technology tailored for ice operation by utilizing their core know how and technologies. The development includes improved control algorithms, testing of the systems and utilising new more intelligent technology to overcome the ice challenges. The development work will take place in close co-operation with Aker Arctic Technology in Helsinki and Navis Engineering R&D Centre in St. Petersburg. The joint project aims to provide more energy efficient and capable and safe DP-systems especifically developed for ice operation.

Kongsberg Launches DPS for Workboat Market

Last month Kongsberg Marine launched the Compact DP Series from Kongsberg Maritime. A solution for the smaller vessel and operator, it offers a complete DP class 1 solution for dynamically positioned vessels and is designed to meet the requirements of Offshore Service Vessels and workboats. The system consists of two main components, the cPos and cJoy, both of which use Kongsberg RCU technology, within the (cPos or cJoy) Compact Controller. This forms the heart of the system and is scalable to fit any DP class 1 system. The controller's main function is to implement DP and joystick control algorithms, take actions as to operator commands and the information collected and processing from the various sensors in the DP system.

Kongsberg Launches DPS for Workboat Market

Last month Kongsberg Marine launched the Compact DP Series from Kongsberg Maritime. A solution for the smaller vessel and operator, it offers a complete DP class 1 solution for dynamically positioned vessels and is designed to meet the requirements of Offshore Service Vessels and workboats. The system consists of two main components, the cPos and cJoy, both of which use Kongsberg RCU technology, within the (cPos or cJoy) Compact Controller. This forms the heart of the system and is scalable to fit any DP class 1 system. The controller's main function is to implement DP and joystick control algorithms, take actions as to operator commands and the information collected and processing from the various sensors in the DP system.

News: Kongsberg Launches DPS for Workboat Market

Kongsberg Marine launched the Compact DP Series from Kongsberg Maritime. A solution for the smaller vessel and operator, it offers a complete DP class 1 solution for dynamically positioned vessels and is designed to meet the requirements of Offshore Service Vessels and workboats. The system consists of two main components, the cPos and cJoy, both of which use Kongsberg RCU technology, within the (cPos or cJoy) Compact Controller. This forms the heart of the system and is scalable to fit any DP class 1 system. The controller's main function is to implement DP and joystick control algorithms, take actions as to operator commands and the information collected and processing from the various sensors in the DP system.

SWM Uses Automation To Speed Workflow

The ability of ship repair yards to quickly, efficiently and effectively get ships in and out in the least possible amount of time is cornerstone to their very existence. Southwest Marine in San Diego has recently adopted an advanced, automated floating dry dock control system, which promises to ensure these lofty goals are met. In May 1999, Randy Jaeger a project manager at Southwest Marine (SWM) in San Diego, Calif., contacted IDAC West to discuss retroffitting their floating dry dock with a new automatic control system. SWM's 22,000-ton Floating Dry Dock, known as "Pride of San Diego" that is typically used for Naval Ship repair, had an existing control system that had become outdated and difficult to maintain.

SHI Develops RTLinux Powered Robots

FSMLabs, a software developer announced that Samsung Heavy Industries Shipbuilding Division (SHI) has selected RTLinuxPro as the base for its robotics systems and has several advanced RTLinux powered robots in production use. Working with FSMLabs' Korean partner, RealTimeWave, engineers at SHI have created some of the worlds most advanced ship-building robots including an autonomous “Spider” welder that autonomously guides itself over the ships membrane wall. In addition to the Spider robot, SHI has developed a RTLinux powered pipe alignment robot also in production use and a third, Stewart-Gough Type 6-axes parallel robot is under development. The robots use SHI designed 3-D path tracking and real-time attitude control systems.