First of Robert Allan Ltd.'s RAstar 4000-DF Class Dual Fuel Extreme Escort Tugs Delivered to Østensjø Rederi AS

The first of three new dual fuel RAstar 4000-DF class extreme escort tugs, the Dux, has been delivered to Østensjø Rederi AS by Spanish shipbuilder Astilleros Gondán S.A. Designed by Robert Allan Ltd., the 40.2 meter vessel is the first of a three boat order from Østensjø for severe weather operations at Statoil's Melkøya LNG Gas terminal at Hammerfest in the extreme north of Norway. These escort tugs will conduct approximately 300 LNG ship escorts annually, assist with berthing operations and will be maintained in readiness for emergency services such as long line towing, firefighting and oil spill response.

The designer said Statoil's requirements for these vessels were challenging: extremely high escort performance, high free running speed, low flash point oil recovery and storage, towing from both ends, and compliance with IMO III emissions standards, all under harsh environmental conditions. To satisfy these requirements within a 40 meter overall length required innovative thinking and close collaboration between owner, designer, classification society, builder and major equipment suppliers. The distinctive design of the RAstar 4000-DF is the result.

Particulars and Capacities

Key Particulars

- Length: 40.2 m

- Beam: 16 m

- Depth (Least Molded): 6.1 m

- Draft Max: 7 m

- GT: 1,056

Capacities

- LNG (gross tank capacity): 33 m³

- Diesel Fuel Oil: 313.8 m³

- Fresh Water: 45.6 m³

- Recovered Oil: 254.4 m³

- Foam: 20.4 m³

- Dispersant: 20.4 m³

LNG Solution for IMO Tier III Compliance

Østensjø proposed a dual-fuel solution (LNG and diesel) to address the charterer's requirement to comply with IMO Tier III emissions standards. The gas fuel installation consists of a Wärtsilä "LNG Pac" (IMO-Type C vacuum-insulated LNG tank with Tank Connection Space (TCS) located in the LNG tank hold, and two Wärtsilä 6L34DF Dual Fuel (DF) main engines. Each TCS contains the LNG tank connections (liquid and vapor), a Pressure Build-Up Evaporator (PBE), a Main Gas Evaporator (MGE) and the Gas Valve Unit for each engine. The tank hold is designated as a nonhazardous space accessed from the engine room by means of an A-60 rated watertight door. The TCS is accessed from within the tank hold by an air lock, which is integrated with the TCS and is supplied as part of the LNGPac system.

The engines and engine room are configured to be "gas safe". All gas supply piping is double wall. The outer annulus of gas supply piping is under-pressure ventilated at 30 air changes per hour and is equipped with gas detection and flow sensing.

The LNG bunker station is on the main deck. LNG bunkering is possible either from a tank truck or a bunkering barge. A foldable drip tray at the bunker station and provisions for water flushing protect the hull from gas spills.

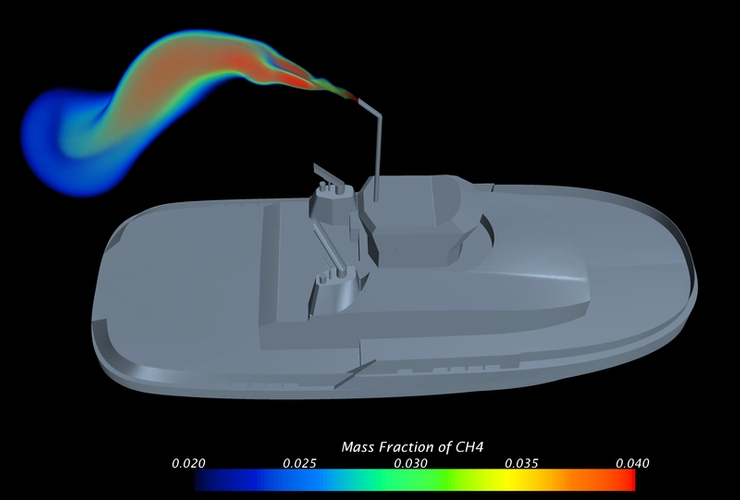

A vent mast serves as an outlet for small quantities of gas released by pressure relief valves and "block and bleed" valves in piping. Although the outlet is normally required to be at least 10 meters away from potential sources of ignition such as engine exhaust outlets, the relatively small size of the vessel and need to keep the mast low for ship handling operations made this impractical. Instead, to keep the mast as compact as possible, Robert Allan Ltd. developed a unique double wall vent mast. Ventilation air forced through the outer annulus mixes with any vented gas carried by the inner pipe at the outlet. The resulting mixture is carried safely away by the ventilation air flow. To prove the effectiveness and safety of this arrangement, Robert Allan Ltd. used its powerful CFD capability to study the gas dispersion around the vessel for a range of gas release scenarios and wind conditions. The results of this study were applied in the risk assessment process conducted with the classification society Bureau Veritas.

Built for Speed

To connect to the relatively fast moving incoming tankers, the RAstar 4000-DF is capable of a free running speed of more than 15 knots. A detailed CFD study focusing on stern shape and testing various different nozzle geometries was conducted in order to ensure these high free running speeds could be achieved. SCHOTTEL's VarioDuct SDV 45 nozzle which provides improved efficiency at higher speeds was under development by SCHOTTEL at the same time and the RAstar 4000-DF ended up being the first vessel to be fitted with this new nozzle profile.

Extreme Escort Forces

The RAstar 4000-DF is designed to generate high escort forces, and has been BV approved for a rated Fs of 167 metric tons indirect steering, and more than 200 metric tons braking at 10 knots. To achieve this, Robert Allan Ltd. applied BV-approved CFD based prediction methodologies during design, and verified the predictions through extensive self-propelled model testing at the Vienna Model Basin.

Harsh Environment

To operate under harsh winter weather and sea conditions and low ambient air and water temperatures, the RAstar 4000-DF has a number of special features. Its hull form is optimized for excellent sea-keeping. Both fore and aft winches are enclosed in insulated and heated winch rooms. Exposed working decks have heat tracing to reduce ice build-up. The wheelhouse is fitted with heated windows and an efficient combination electric/oil fired boiler provides hot water for domestic heating, domestic hot water supply, pre-heating for engines and heating for recovered oil tanks.

Emergency Response

A foam-capable external firefighting system with water spray protection is fitted with capacity to deliver streams of water totaling 2,400 m3/hour at ranges in excess of 120 m (Class Fi-Fi 1 standard). Two pumps of 1,500 m3/hour pumps are driven through step-up Kumera gear boxes driven off the front of the main engines. The monitors are rated for 1,200 m3/hour of water and 300 m3/hour foam. Additionally 4 x DN100 NOR couplings are located P&S for delivery of fire-fighting water to the terminal.

Oil Recovery Equipment

- Inflatable oil boom on a separate hydraulic powered drum

- Hydraulic-driven oil skimmer and floating hose stored in the cargo hold deployed by vessel deck crane

- Four internal hull storage tanks for recovered oil and capable of dual service (two ballast and two reserve fuel oil) when not used for recovered oil

- •5" (125 mm) recovered oil loading connection for direct hose connection to the skimmer discharge

- The rec-oil discharge system has heating coils in the recovered oil tanks, four hydraulic driven submersible discharge pumps each of 60 m3/hour with variable speed from 0 – 100 percent rpm pumping through 100mm lines to the discharge manifold and 125 mm offload connection

- Oil dispersant system complete with a 20.3 m3 tank, pump and pipelines for mixing and two spray booms

Propulsion and Power Generating Machinery

- Two dual fuel main engines Wärtsilä model 6L34 DF with MCR 3,000 kW at 750 rpm

- 2 x Schottel SRP 3030 CP with 3.4 meter controllable pitch propellers and SDV 45 speed nozzles

- Tunnel Thruster: Schottel STT 170 T-FP 250 kW hydraulically-driven and located in an independent watertight compartment inside the skeg and directly below the LNG tank space

- 3 x Volvo D7A TA ship service gensets providing 129 ekW at 1,500 rpm

Fore Deck Equipment

Fore deck equipment is all supplied by Karmøy Winch AS and includes:

- Hawser Winch: Split drum, under-spooled escort towing winch driven by five hydraulic motors with four speed steps. First layer performance is 235 metric tons pull at 4.6 meter/minute at low speed, 27 metric tons at 38 meters/minute top speed, and 300 metric ton brake holding load

- Escort Tow Pins: Fitted forward for use in transit escort mode is a set of 350 mm diameter stainless steel retractable escort towing pins with a SWL of 140 metric tons. These hold the hawser in position and prevent the tug yawing when running at speed with a relatively light line behind the tug. When required to operate in indirect mode the pins are rapidly opened and dropped and the line moves aft to the staple

- Anchor Windlass: Two low profile vertical axis anchor windlasses for 26 mm chain

- Capstan: 400 mm diameter with pull of 5 metric tons at 20 meters/minute

Aft Deck Equipment

Aft deck equipment supplied by Karmøy Winch AS includes:

- Aft Towing Winch: Single drum, under-spooled towing winch fitted in the heated winch room. Driven by four hydraulic motors with 4 speed steps. First layer performance is 131.5 metric tons pull at 8.1 meters/minute at low speed, 29 metric tons at 32.6 meters/minute top speed, and 300 metric ton BHL. The drum has a capacity of 1,000 meters of 64 mm diameter steel wire rope

- Combined Karm Fork and Tow Pins: Fork can accommodate up to 102 mm chain and has a SWL of 300 metric tons. The towing pins with rotatable top flanges are rated 160 metric ton SWL

- Tugger Winch: 9 metric ton pull at 30 meters/minute

- Capstan: 400 mm diameter with pull of 5 metric tons at 20 meters/minute

Also fitted on the aft deck above the aft winch room is a 65 T-M Palfinger PK 65002 knuckle boom crane.

Fendering

The tug is heavily fendered for the expected high swells. Bow fendering consists of a 1,000 mm diameter cylindrical fender extending well aft along with a lower course of 400 mm thick W-fender specially designed to limit fender contact pressures to 20 t/m2. Sheer fendering is 400 x 400 mm D-fender. Stern fendering is 400 mm thick W-fender.

Accommodations

The accommodations are arranged to be generous and comfortable for a crew of eight. The main deck features a generous sized mess and galley, the Master's cabin, a large office, and a wet gear/locker room with toilet space. The lower deck includes four MLC- compliant cabins, each with en suite toilet, for up to seven crew. The lower deck also contains a large gym, laundry and galley store. The wheelhouse is fitted with a single control console with winch operator position, and provides the Master with excellent all-around visibility and clear sightlines from the console.

Dux and her sisters embody the years of experience of the designers and the careful work of the builders in providing the highest standard of acoustic and vibration isolation techniques throughout. The result is a quiet ship throughout. Noise level measurements on trials were as follows:

- Bridge: 56 dBA

- Mess/Lounge: 50.8 dBA

- Master's Cabin: 50 dBA

- Lower Deck Crew cabins: 45-47 dBA

- Machinery Control Room: 73 dBA

The vessels have been constructed to Bureau Veritas Class requirements with the following notation:

BV + 1+Hull, +MACH, ESCORT TUG (Design Maximum Steering Force = 167 t, Design Maximum Braking Force = 212 t, Rated Escort Speed = 10 knots), FIRE FIGHTING SHIP 1, WATER SPRAYING, OIL RECOVERY SHIP, DUAL FUEL, UNRESTRICTED NAVIGATION, +AUT UMS

On trials, the vessel exceeded all performance expectations achieving an ahead bollard pull of 107.5 metric tons, astern bollard pull of 103 metric tons, and a free running speed ahead in excess of 15 knots.

The RAstar 4000-DF escort tugs, custom designed for Statoil's Melkoya facility raise the bar significantly for both ASD escort tugs and also LNG powered terminal tugs. They will play a critical role in ensuring safe and efficient movement of LNG carriers at the Melkoya facility for proud Owners Østensjø Rederi AS.