The Importance and Value of Marine Industry Training

Port Safety and Security Industry Training Program – Summer 2013

The Coast Guard Marine Industry Training Program offers incredible opportunities for Coast Guard employees to intimately learn specific facets of the marine industry. Participants of the program work directly for industry partners for up to 1 year. In addition to building superior government/industry working relationships, the program affords industry sponsors an opportunity to share detailed business considerations and limitations, so that Coast Guard regulatory activities most effectively promote safety, while limiting undue burden on the maritime industry.

Industry Training History and Opportunities

There is a rich history of collaboration between the Coast Guard and the maritime industry. Following World War II, the Coast Guard permanently assumed the duties and responsibilities of the Bureau of Marine Inspection and Navigation, marking the first time that all functions of maritime safety fell under one federal agency. Subsequently, the Coast Guard established the Industry Training Program in 1948 to further enhance merchant marine safety efforts. Today, Title 14 U.S. Code § 59 mandates the Coast Guard Marine Industry Training Program, whereby employees may be assigned to a private entity to further the institutional interests of the Coast Guard with regard to marine safety.

Coast Guard Headquarters Office of Shore Forces (CG-741) administers the program through internships with maritime industries, organizations, and associations. The program is similar to participating in a fast-track junior executive training program, where trainees focus on Port Safety/Security Industry Training (PSSIT); Marine Environmental Protection (MEPIT); Investigations (IIT); and Merchant Marine (MMIT) issues. Industry training is conducted in conjunction with a Permanent Change of Station and is considered “Duty Under Instruction.” Twelve junior officers conduct industry training each year; each sub-program is normally allotted one 1-year training allowance billet and two 4-6 month training billets.

This past summer, I participated in PSSIT, in which I worked at the American Petroleum Institute (API) in Washington, DC and the Delaware Bay and River Cooperative (DBRC). In addition to building relationships with numerous industry partners, I polished my understanding of the collective efforts to strengthen marine contingency planning.

Industry Involvement in Strategic Planning

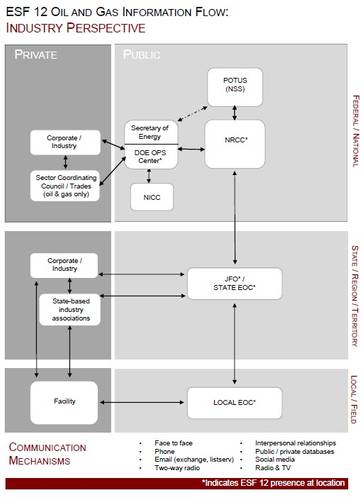

API is the largest oil and natural gas industry trade association, representing over 500 production, refining, distribution, and service companies. While at API, I learned the importance and value of industry trade associations. In the wake of Hurricane Sandy, API led the “whole community” effort to develop the National Response Framework (NRF) Emergency Support Function (ESF) #12 – Energy Annex information flow and process model. This model (Figure 1), and the supporting Oil and Natural Gas (ONG) Industry Emergency Preparedness and Response Handbook, educate and bolster efficient and effective communication and response amongst government regulators, public communities, and other stakeholders before, during and after any incident.

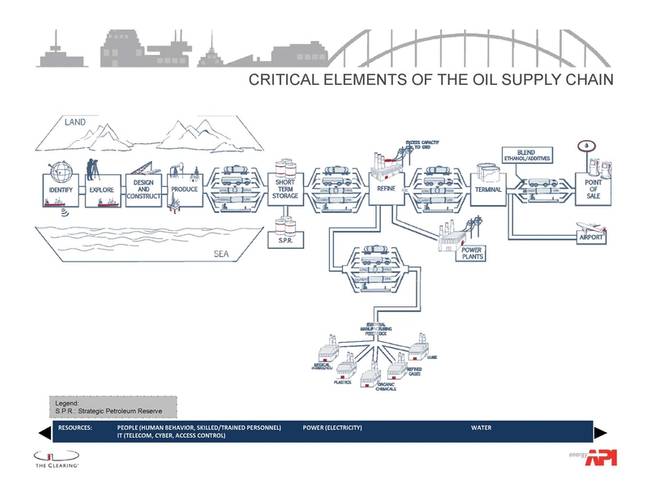

The National Preparedness System, National Response Framework, and the Incident Command System provide the frameworks and processes that should be utilized by all stakeholders in responding to any event. ESF’s are comprised of 15 essential services needed during incidents, and support the frameworks by providing the structure for coordinating resources and capabilities across public and private infrastructure. As evidenced by the response to Hurricane Sandy, the frameworks and processes are just that – processes. To be most effective, users must understand how the critical elements of each ESF interface. Effective response requires the most efficient delivery of resources and information to ensure populations are secured and that essential services are provided in a timely manner. The strategic focus of response and recovery efforts following Hurricane Sandy should have been the critical elements of the ONG supply chain, as opposed to the 3,500+ individual point-of-sale locations in the greater tri-state area.

API seized the opportunity to improve future ESF #12 response by increasing educational outreach efforts of the oil and natural gas supply chain (Figure 2). As part of the Marine Industry Training Program, one of my projects was to work with interagency partners to determine the essential infrastructure assessment considerations, government/industry response actions, government/industry critical information requirements, and potential government regulation waivers. This information was integrated into clear and succinct flow charts which will be utilized by key decision-makers during future responses.

API did not create these tools in a vacuum; a collaborative and iterative development process was utilized, where government regulators and ONG industry partners developed and refined these products over several months. Government participants included: White House National Security Staff; Department of Energy and Energy Information Agency; Department of Homeland Security Office of Infrastructure Protection, Federal Emergency Management Agency and U.S. Coast Guard; Department of Interior and Bureau of Safety and Environmental Enforcement (BSEE); Department of Transportation; and Environmental Protection Agency. Oil and Natural Gas Industry participants included: International Liquid Terminals Association (ILTA); Petroleum Marketers Association of America (PMAA); Interstate Natural Gas Association of America (INGAA); American Fuel and Petrochemical Manufacturers (AFPM); Sigma; and others.

The efforts of the interagency and industry working group were presented to the President at the 2013 Hurricane Season Briefing. The White House subsequently recommended that the ESF #12 information flow model (Figure 1) be utilized as a foundation to design information flow models across all 15 ESFs. Further information on this effort and other API information can be found at www.api.org.

Industry Involvement in Operational Planning

Upon completion of my time at API in early July, I transitioned to DBRC. There, I further refined my understanding of the oil and natural gas industry and came to fully appreciate the efforts of oil spill response organizations. The DBRC is a not-for-profit corporation formed in 1977. As a prominent member of the Sector Delaware Bay Area Committee, DBRC plans for and responds to oil discharges and hazardous substance releases in the Delaware River, Delaware Bay and the surrounding Atlantic Ocean.

Area committees are comprised of federal, state, local, non-governmental organizations, private-sector industry and community members. U.S. Coast Guard and Environmental Protection Agency representatives serve as Federal On-Scene Coordinators (FOSC), managing all pollution and hazardous substance response activities throughout the United States. Following amendments to the Federal Water Pollution Control Act (FWPCA), area committees are charged with maintaining area contingency plans (ACP) that provide guidance to prevent, mitigate and remove worst case discharges from vessels, offshore, and onshore facilities. DBRC’s intimate knowledge of environmentally sensitive areas and oil spill response planning laid the foundation for the Sector Delaware Bay ACP. This plan not only drives efficient and effective response to events such as the M/T ATHOS 1 oil spill, it also enables coordinated prevention, response and recovery efforts for all contingencies. Incorporating the refined ESF coordination strategies into operational and tactical plans (such as the Sector Delaware Bay ACP) will prove to be invaluable during future multi-faceted incidents like Hurricane Sandy.

Historically, over 1 million barrels of crude oil have been imported via the Delaware Bay and River each day. Today, the port also serves as a key ONG export conduit because of its geographic location, existing ONG infrastructure, and access to shale oil and natural gas. As world ONG markets continue to shift, response plans must also adapt to changing economic and environmental conditions. My primary and ongoing project at DBRC has been to identify and transition the geographic response plans and booming strategies contained within the ACP to into an accessible computer-based platform. Identified options must be accessible to all port partners and remain usable during all contingency events, including mandatory evacuations, power, and internet outages. Utilizing an interactive geographic information system (GIS) that is functional on multiple platforms, such as Environmental Systems Research Institute’s (Ersi) ArcGIS, Google Earth, or the National Oceanic and Atmospheric Administration’s (NOAA) Environmental Response Management Application (ERMA), will ensure the ACP remains dynamic, relevant and useful during all types of events. The Sector Delaware Bay ACP and further information on DBRC can be found at www.dbrcinc.org.

The Value of Industry Training

As I gained detailed port and business knowledge by visiting and learning from numerous port partners, I connected the strategic, operational and tactical level interdependencies amongst communities, industry and government. The visited organizations include: Pilots Association and Mariners Advisory Committee for the Bay and River Delaware; Maritime Exchange for the Delaware River and Bay; Philadelphia Regional Port Authority; South Jersey Port Corporation; Gallagher Marine Systems; Atlantic Logistics; Kinder Morgan; Vane Brothers; NuStar Asphalt; PBF Energy; Monroe Energy; Sunoco Logistics; Overseas Shipholding Group; Philadelphia Energy Solutions; Tri-State Bird Rescue and Research; Marine Spill Response Corporation; Miller Environmental Group, among others. Only after detailed exposure to these organizations did I fully understand the importance of oil spill response strategies and contingency plans such as the ACP.

The Coast Guard Marine Industry Training Program is an invaluable opportunity for both CG and industry participants. As I settle into my new billet as Sector Delaware Bay’s Marine Environmental Response Branch Chief, the relationships that I have built and the knowledge I have gained during industry training are already paying dividends. Sustained Coast Guard and maritime industry participation and collaboration through the industry training program will further enable sensible regulation and maritime safety for years to come.

Interested Coast Guard applicants can find detailed information by searching industry training on CGPortal. Interested industry sponsors can explore future training possibilities with CG-7411 by calling (202) 372-2366.

“The views expressed herein are those of the author and are not to be construed as official or reflecting the views of the Commandant or of the U. S. Coast Guard.”