AME Hires Paul Savage as Operations Manager

Fort Lauderdale, Fla. based maritime and industrial mechanical service repair specialist Advanced Mechanical Enterprises (AME) announced it has appointed Paul Savage as its new Operations Manager.With over 30 years of leadership and project management experience, Savage joins the AME management team from Veolia North America, where he served as Vice President, managing complex industrial and government contracts. At Veolia, Savage was at the helm of commercial, state, and federal contracts…

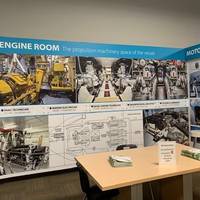

'Sea the World' Reveal At Huizenga Center

South Florida’s marine industry is a $12 billion/year economic engine that provides the region with 142,000 careers and jobs. With an aging workforce and a unique skill set, the maritime community is facing a workforce that’s aging out with skilled labor being very hard to find. To assist, Advanced Mechanical Enterprises/AMESOLUTIONS.COM, and 23 marine industry companies have joined forces with Junior Achievement of South Florida.On May 1, 2019, Junior Achievement of South Florida will unveil the Marine Industry Storefront…

AME Expands into Hydraulics

Advanced Mechanical Enterprises (AME) has added hydraulic service and repair to its broad range of predictive, preventative and corrective maintenance solutions. “Adding hydraulics to our line of services was a natural progression for AME. We have two-full machine shops that can quickly help troubleshoot hydraulic issues as well as trained hydraulic technicians on staff that are readily available,” said Rich Merhige, President, AME. The Fort Lauderdale, FL-based company's newly formed hydraulics division will be led by industry veteran…

Voices: Rich Merhige, President/Owner, AME

AME is a Florida based engineering services company specializing in marine (Advanced Mechanical Enterprises) and industrial (Advanced Maintenance Engineering) predictive, preventative and corrective maintenance for rotating and reciprocating machinery. Founded by Rich Merhige in 1992, AME has pioneered the use of technologies and equipment to perform diagnostics, maintenance and repair, particularly for private and commercial vessels. As AME celebrates its 25th anniversary, discuss the decision to start the company.

AME to Showcase Windrock’s New 6400 Diesel Engine Analyzer

For the eighth year in a row Advanced Mechanical Enterprises (AME) will be showcasing at the International WorkBoat Show (IWBS), the largest commercial marine tradeshow in North America serving people and businesses working on the coastal, inland and offshore waters. AME will exhibit an array of services and products they provide and distribute, including Wartsila PSE shaft seals and Envirosafe Composite Bearing material. To coincide with Windrock’s recent launch of their new 6400 Diesel Engine Analyzer, a model will be on display for viewing. Operators, mechanics and engineers worldwide rely on Windrock diagnostic solutions to increase reliability, improve performance and reduce engine failures of diesel engines in industrial applications.

MN100: Advanced Mechanical Enterprises

AME President Richard Merhige has pioneered the use of lasers in the marine industry. AMEsolutions.com is comprised of Advanced Mechanical Enterprises/AME and Advanced Maintenance Engineering/AME, comprehensive marine and industrial engineering services companies specializing in Predictive, Preventative and Corrective Maintenance for rotating machinery. Since 1992, AME has pioneered the use of the most cutting-edge technologies and state-of-the-art equipment to the diagnostics, maintenance and repair of rotating machinery, particularly for private and commercial vessels.

Keeping Machinery in Line with Laser Alignment

If you operate a vessel, its machinery, without a doubt, will require alignment many times during the course if its life. When misalignment is present components will be worn, efficiency will be lost, and, if left uncorrected, mechanical failures are imminent. This translates into a strain on mechanical systems, your budget, and your peace of mind. When speaking of alignment in marine applications, it is usually shaft alignment that is being referenced. Shaft alignment is defined as the positioning of two or more machines which so that at the point of power transfer from one shaft to another…

Online Monitoring Systems Can Improve Your Bottom Line

All operators, regardless of vessel type, size, location or function, are plagued by the same worries: “When will my next outage happen, and what is it going to cost me?” In an effort to ease these concerns, millions of dollars are invested every year into commercial/workboat maintenance programs. But how can maintenance be maximized without blowing budgets? What’s the most thorough way to monitor equipment? How can all mechanical components be watched for possible issues and failures?

Murray & Associates Hosts Third Fishing Challenge

A group of industry professionals from the commercial maritime sector gathered in Fort Lauderdale, Fla. at 8 a.m. on February 8 to participate in Murray & Associates LLC’s 2014 Fishing Challenge. The naval architect and marine engineering group hosted the tournament for the third consecutive year as a way to gather clients and maritime business professionals for a day of fishing on Florida’s beautiful waters. In total, the tournament drew 60 participants, including representatives from…

Remote Monitoring: The Bottom Line for Fleet Optimization

By any yardstick, remote monitoring is fleet optimization in the new millennium. You’re all over it: optimizing your fleet. But, what does that mean? For some operators, it means making sure their mix of vessels meets the needs of their customers and the prevailing winds of the economy. For others, it entails reading the tea leaves just right when it comes to deciding on time charters or dipping one’s toes into the spot markets. Still others focus on the closely linked Holy Grail of reduced bunker consumption and minimal stack emissions. For all of these cool customers, however, “remote monitoring” will also be part of that equation. That said; defining what remote monitoring means is another thing altogether. Remote monitoring of on board metrics or data points is here.

Maintenance: How Well Do You Listen?

A predictive / preventative maintenance program that includes vibration analysis can help save time and money. Are you one of those people who “listen to your gut?” If you are in charge of a vessel’s maintenance program – listening to your machinery is vital to its livelihood. And, if it’s in high demand, or on a tight schedule, chances are your livelihood, and that of your crew, is at stake too. Vibration is annoying and uncomfortable – easy to notice on a pleasure craft – not so much on a commercial vessel.