Dellner to Launch New Braking System at SMM

International brake supplier Dellner Brakes AB said it will launch new range of ‘plug and play’ electrohydraulic braking systems at this year’s SMM in Hamburg.The new BUEL STL systems provide a compact, self-contained solution for stopping, turning and locking ship propeller shafts on vessels of all sizes, as well as for industrial applications. They are the first to combine technologies from Swedish-based Dellner Brakes and new sister company, Germany’s Pintsch Bubenzer, which the Dellner Group acquired in January this year.As the name suggests…

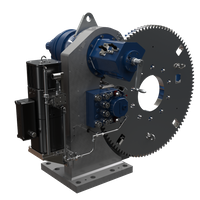

Twiflex: Turning, Locking & Braking System

Regular maintenance of propulsion shafts and propellers requires shafts to be aligned and locked in place so that ships’ engineers can perform the needed work. A Turning, Locking & Braking (TLB) System from Twiflex Ltd. provides a compact solution to allow the shaft position to be set and locked when the vessel is stationary. The Twiflex TLB consolidates three usually separate interfaces and functions into one design package. The modular TLB system is configured to allow customers to select and install one of the turning…

HMS Queen Elizabeth Sets Sail with Dellner Brakes

U.K. Royal Navy aircraft carrier HMS Queen Elizabeth arrived at her home port of Portsmouth last week, fitted with two Dellner Brakes ‘stopping, turning, locking’ (STL) systems that, weighing in at 11,000 kg each, are the biggest STL systems that Dellner Brakes has ever built. Each of the carrier’s two propeller shafts is fitted with a custom-designed Dellner Brakes STL system that allows operators to stop, hold and securely lock each shaft independently, and to individually turn the shafts and giant 33 tonne propellers for maintenance and blade assembly.

Dellner Launches New Lightweight Failsafe Brakes

Braking systems manufacturer Dellner Brakes has rolled out two new spring applied failsafe brakes to its SKP range for cranes, winches, deck machinery, oil rig draw works and other equipment, both on and offshore. Precision engineered in Sweden, Dellner’s new SKP 180 weighs in at 315 kg and delivers braking force from 141 kN up to 226 kN through two brake housings, each containing a powerful spring applied piston. The SKP 4 x 180, weighing 630 kg, combines two brake assemblies containing a total of four pistons to deliver braking force of up to 453 kN.

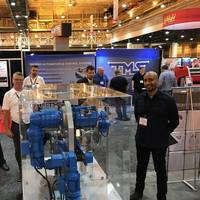

Dellner Brakes Enters the US Marine Market

Dellner Brakes AB chose the 2016 International WorkBoat Show in New Orleans to launch its portfolio of technologically advanced braking solutions, including the world’s first fully automated, electrical ‘stop, turn, lock’ (eSTL) system, to the U.S. marine market. While Swedish-based Dellner Brakes is no stranger to the marine market, and its products are fitted in ferries, tugs, oil tankers, large military ships, multipurpose vessels, luxury yachts and cruise liners all over the world, its U.S. operation has traditionally focused on the industrial sector, operating through wholly-owned U.S.

Dellner Brakes Introduces Electrical STL System

Manufacturer of technologically advanced industrial and marine braking systems Dellner Brakes AB has launched what it is calling “the world’s first fully automated, electrical ‘Stop, Turn, Lock’ (eSTL) braking system” at September’s SMM 2016 international marine fair in Hamburg. The Dellner eSTL system is compact and needs no additional piping, making it quick, easy and cost effective to install, the manufacturer said – especially where space is at a premium. It’s simple to use…

ASIS's 7.5m RIBs Get Their Sea Legs

ASIS Boats announced the completion of the first of the new production series 7.5m Asis RIBs to be equipped with Sealegs System 60 amphibious technology. The 7.5m Asis Midi will include the two-wheel drive and automatic braking systems as well as power steering and high quality, marine-ready Sealegs components. Powered by a 150HP Evinrude E-Tec on the water, the craft reaches speeds of up to 39 knots. Featuring Hypalon Tubes, 180 litre fuel tank and self-draining deck, the Asis 7.5 Midi is also equipped with four straddle style seats designed for additional comfort and lateral stability.

MagnaShear Brakes to be Featured at WorkBoat

The MagnaShear marine duty motor brake from Force Control Industries will be featured in booth #1862 at the International WorkBoat Show, from December 3-5 in New Orleans, La. These proven brakes employs oil shear technology, providing longer service life even in demanding applications like the frequent start/stop cycles seen on cranes, hoists, winches and other marine material handling equipment. High grade castings, marine duty coatings, stainless steel fasteners and accessories make these brakes an ideal solution for onshore and offshore crane applications.

Altra Industrial Motion Acquires Svendborg Brakes

Altra Industrial Motion Corp. announced that it has closed on the acquisition of Svendborg Brakes A/S and S.B. Patent Holding ApS, the global manufacturer of caliper brakes. Headquartered in Vejstrup, Denmark, Svendborg provides engineered braking systems for a wide range of industrial markets including oil and gas, mining, wind power, marine, metals, material handling and others. “Svendborg is a leading brand that provides Altra with new technology and access to a number of new geographic regions,” said Carl Christenson, Altra's president and CEO. Svendborg joins Wichita Clutch, Industrial Clutch, Twiflex Limited, Formsprag Clutch, Marland Clutch and Stieber Clutch…

Matthias Grawe to Head Business Division Industry

Matthias Grawe took over at the helm of the Division Industry at Voith Turbo on March 1. The graduate engineer has been working for Voith Turbo for ten years, most recently as Head of the Product Group Variable-Speed Drives at the location Crailsheim. After studying process technology at Stuttgart University, followed by a study course in energy management at Grenoble University, Grawe gained international experience in a number of renowned companies. In 2000, he joined Voith as sales manager in the Product Group Variable-Speed Drives at Voith Turbo in Crailsheim…

TT Club Addresses Crane Safety in Windy Conditions

Analysis of the TT Club’s claims over a number of years has highlighted that wind damage to quayside cranes is the biggest weather related cost to terminals. Due to their size, profile and location on the quayside, these cranes are particularly susceptible to wind, and care must be taken in the design and operating procedures to protect against the crane being blown over or along the rails. Such incidents can be prevented, or at least the collateral damage caused can be restricted, by having appropriate procedures and ensuring that they are followed. Essential elements include: having effective national and local weather forecasting systems and ensuring that operational procedures respond appropriately when sufficient warning is forthcoming.

Jeamar's Winches Are Customized To Order

Jeamar Winches has commenced a new program, dubbed "Build to Order," whereby winches are designed and manufactured specifically to client requirements. The new program can customize products, such as a double drum lifting winch with grooved drums, two independent fail safe braking systems - one hydraulic and one electromechanical, plus a travel limit control.

USCG Issues Bulletin on Crane Safety

Recently, an incident occurred where a 1740-ton shipboard mounted crane boom collapsed. There was a failure of the coupling between the boom winch motor and the wire winch drum. Improperly set brakes on the crane’s winch drums and an inoperable overspeed trip on the winch drum compounded a relatively minor mechanical failure into a catastrophic casualty. This incident resulted in millions of dollars of damage to the crane, crane equipment and the vessel. The vessel was in the process of making a light lift using the shipboard crane when the crane boom started to lower uncontrollably. The crane operator attempted to stop the downward motion of the crane boom by applying the crane’s braking system, but was unsuccessful.