Best Workboats of 2017

Marine News showcases the best of North America’s 2017 workboat deliveries. There is something for everyone. Notwithstanding the lingering offshore energy downturn, there were plenty of bright spots for North American shipyards in 2017. If a hull was delivered in 2017, we took a look at it, with several areas as a focus for inclusion into this edition. For starters, it is always exciting when a domestic yard delivers a vessel – or multiple vessels, for that matter – to foreign buyers. We can compete in a foreign arena; on price, quality and on-time delivery. This year was no different. No less important is the environmental footprint of a vessel, and there was plenty to report on from that angle in the past 12 months. The domestic waterfront is indeed getting greener and cleaner.

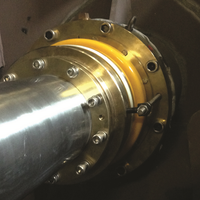

OTI Installs Thordon's Largest TG100 Seal

Offshore Towing Inc (OTI) has completed the refurbishment of its 1974-built 9000hp-class tug Zion Falgout at the Conrad Deepwater shipyard, in Morgan City, La. The milestone project involved the retrofitting of TG100 seals in what marks OTI’s first mechanical shaft seal installation and the largest diameter TG100 series seals ever supplied by Thordon Bearings. An 11.75in (298mm) diameter seal was installed to each propeller shaft of the 66.88t bollard pull twin-screw workhorse.

New Tug, Barge Enter Service for Vane Brothers

Marine transportation provider Vane Brothers has added two newly constructed vessels to the company’s growing fleet: the 4,200-horsepower tugboat Philadelphia and the purpose-built asphalt barge Double Skin 510A. Primarily tasked with towing petroleum barges engaged in the North Atlantic coastwise trade, the Philadelphia is the fifth of eight 4,200-horsepower, model bow tugboats contracted by Vane Brothers through St. Johns Ship Building in Palatka, Fla. The first in the series…

Conrad Delivers Barge to Vane Brothers

Conrad Shipyard recently delivered the DOUBLE SKIN 510A, a 55,000-BBL capacity asphalt barge, to the Vane Brothers Company of Baltimore, Md. The DOUBLE SKIN 510A was constructed at Conrad’s Deepwater South facility in Amelia, La. and will operate out of Philadelphia, Pa.

Vane Bros. Continues Fleet Expansion

Vane Brothers, a marine transportation provider headquartered in Baltimore, has added two vessels to its fleet: the 4,200-horsepower tugboat Hudson and 55,000‐barrel barge Double Skin 601. The Hudson is the second of eight vessels in Vane’s Elizabeth Anne Class of 4,200‐horsepower tugboats contracted through St. Johns Ship Building in Palatka, Fla. The Elizabeth Anne was delivered in January, while the third in the series, the Baltimore, is scheduled for completion this summer.

ACMA Monitors First Dry Dock of TxDOT Ferry

Alan C. McClure Associates (ACMA), a naval architecture and engineering firm, announced that the first dry dock for a ferry being built for the Texas Department of Transportation (TxDOT) has been completed at Conrad Deepwater in Amelia, Louisiana. ACMA and Schuller & Allen provided engineering and design for the new 264-ft vessel, and ACMA is now providing owner’s representation during the construction period until vessel delivery. ACMA Vice President Darrel Harvey said “The ferry’s first dry dock went very smoothly.

Conrad Industries Reports 3Q Results

Conrad Industries, Inc. reported a net loss of $1.2 million and loss per diluted share of $0.16 for the three months ended September 30, 2004 compared to a net loss of $827,000 and loss per diluted share of $0.11 for the third quarter of 2003. the third quarter of 2003. compared to $26.5 million for the same period of the prior year. September 30, 2003. 2003. compared to gross profit of $741,000 (2.8% of revenue) for the first nine months of 2003. nine months of 2004 compared to the same periods in 2003. in 2003. production hours associated with the entry into the aluminum business and the execution of our backlog. steel. project totaling approximately $544,000. additional work while we waited for the notice to proceed from the customer. surging prices of steel and other price increases.