HMM Plans Onboard Carbon Capture Field Test

Hyundai Merchant Marine (HMM) has announced plans to conduct field tests of an onboard carbon capture system following a feasibility study of the technology for container ships.The project is being conducted with Samsung Heavy Industries (SHI) and PANASIA in the second half of this year.The feasibility study revealed that the system could be installed without changing the existing equipment of the ship and does not hinder the stability of vessel operation.The collected CO2 will be liquefied in a pressurized tank and used for manufacturing dry ice on land.Earlier this year…

BMT Subsea Technology for Equinor

Global engineering company BMT announced a partnership with Sonardyne to deliver to Subsea 7 its proven ‘Riser Monitoring System’ (RMS).The subsea integrity monitoring solution has been adopted by the world’s largest spar platform, Aasta Hansteen.The Aasta Hansteen Spar platform is operated and owned by Equinor ASA, the Norwegian multinational energy company.Located 300 kilometres west of Sandnessjøen on the Norwegian Continental Shelf (NCS) in water depths of up to 1,300m, the deepest field development on the NCS, the Aasta Hansteen Spar is installed in a harsh environment utilising highly robust deepwater Steel Catenary Risers (SCR).Neil Charles…

Alfa Laval's DuroShell Heat Exchanger for LNG

Optimized for use as an LNG vaporizer, the robust DuroShell provides higher thermal efficiency than conventional plate-and-shell designs, as well as market-leading fatigue resistance. Thanks to new research into glycol freezing, it can now be used in even more compact and cost-effective installations.“The continued rise in the number of vessels sailing with LNG is one of the most significant trends in today’s marine industry,” says Jonny Hult, Head of Marine Heat Transfer Equipment at Alfa Laval.

Inert Gas Production for Alfa Laval Training Center

An Alfa Laval Smit Combustion system (FU type) is now installed at the Alfa Laval Test & Training Center in Aalborg, Denmark. The system, which adds inert gas production to the center’s already comprehensive range of full-scale vessel applications, will ensure that Alfa Laval remains at the forefront of developing and optimizing inert gas systems.Inaugurated in 2014, the Alfa Laval Test & Training Center is essentially a full-sized machine room on land, with equipment from all of Alfa Laval’s marine product groups installed in process lines as they would be on a commercial vessel.

Alfa Laval's GCU Sales Exceed 100 Units

The Alfa Laval Gas Combustion Unit (GCU) has been chosen for boil-off gas management on more than half of the LNG carriers built during 2018. This brings the total number of GCUs sold to well over 100 units, with new developments promising still greater market potential.Since buying the fledgling technology from Snecma in 2013, Alfa Laval has proven the GCU concept and built up a strong position for the product in the LNG market. This simple and reliable incineration unit for boil-off gas…

Wärtsilä, GTT Partner on LNG Solutions

Wärtsilä and GTT finalized a cooperation agreement at the Marintec conference and exhibition in Shanghai, China on December 5. The aim of the cooperation is to explore potential business opportunities in the marine sector in relation to liquefied natural gas (LNG) storage, fuel gas supply systems and associated services that will benefit both shipyards and vessel owners. Wärtsilä has experience and in-house expertise in LNG fuel gas applications, as well as gas carrier process know-how, while GTT has capabilities in developing cryogenic membrane containment solutions. By collaborating in the delivery of jointly agreed projects, the two companies will be able to propose solutions that optimize onboard LNG fuel gas storage and operations.

VOSSRing Certified for Marine and Gas Applications

In combination with the VOSSRing preassembly studs, VOSSRing also meets the demands placed on assembly reliability and leak prevention, as confirmed by a series of certifications such as the recent permit for gas applications. The cutting ring had already been granted certificates for the marine and offshore sectors from all major international classification societies. It is now seamlessly integrated into the fluid specialist’s complete range of couplings: they are mostly approved for both the marine and offshore sectors as well as for gas applications.

ABS Addresses Marine and Offshore Industry Challenges

ABS held its annual Marine and Offshore Technical Committee Meetings in Houston in early May and addressed industry challenges and sharpen focus on future needs. “Collaborating with significant and recognized industry leaders representing ship owners, yards, operators, equipment manufacturers and vendors helps guide our research and development focus,” said ABS Chief Technology Officer Howard Fireman. Fireman identified four key focus areas that will help industry deal with this new data-centric world: data collection, data security, data management and data analytics. Together, these areas make up ABS FutureClass™ - ABS’ approach to leveraging real-time data to improve decisions and increase operational efficiencies.

WIN WIN: Wind Powered Oil Recovery Concept Progresses

The DNV GL-led joint industry project, WIN WIN (WINd powered Water INjection), has completed its first phase and determined that wind power could be used to power offshore water injection. The project is currently moving into its second phase, which includes refining and testing the electrical systems, and investigating possibilities for broader applications. The project consists of four partners: DNV GL, ExxonMobil and ENI Norge – all part of the first phase – and the Norwegian Research Council – a new participant for this second phase.

Viega Introduces New Reducer and Union Fittings

Twelve new P x P reducer and P x FPT union options are available for the Viega MegaPress and MegaPressG systems for carbon steel piping systems. Viega said it has introduced 12 new reducer and union options for the Viega MegaPress and MegaPressG systems for schedule 5 to schedule 40 carbon steel piping systems in sizes 1/2" to 2". The Viega MegaPress system uses modern cold press connections for pipe installation. The Viega MegaPress system is ideal for hydronic heat, chilled water, compressed air, fire sprinkler systems, low-pressure steam and vacuum lines.

Wanner Debuts Q155 Series Quintuplex Pumps

Wanner Engineering, Inc. has introduced its new Q155 Series Quintuplex seal-less pumps (low pressure models) designed for a variety of applications including reverse osmosis in water and wastewater treatment, mine dewatering, salt water disposal, salt water injection, bulk transfer, hydraulic lift and steam generation. The Q155 Low Pressure line includes three models: Q155E with a maximum flow rate of 157 gpm (595 l/min) and maximum discharge pressure of 1500 psi (103 bar); Q155F with a maximum flow rate of 127 gpm (490 l/min) and maximum discharge pressure of 1850 psi (127 bar)…

Hyundai Bags Order for 2 LNG Carriers from SK Shipping

Hyundai Heavy Industries Co. (HHI) struck a $400 million worth deal to build two liquefied natural gas (LNG) carriers for SK Shipping Co., a Korean shipowner. According to the sources, the vessel can carry 180,000 cubic meters of LNG. The vessels will be delivered starting in the first half of 2019, the sources said. Meanwhile, a press release from the French LNG containment specialist GTT said that it has received an order for two new LNGCs (Liquefied Natural Gas Carriers) for HHI. The vessels will be built at Hyundai's shipyard in Ulsan for SK Shipping. Delivery is scheduled in 2019. The vessels, designed according to the new IGC standards published in 2016, will be equipped with GTT's Mark III Flex membrane technology.

GTT Receives Order for Two LNG Carrier Newbuilds

GTT has received an order from Hyundai Heavy Industries (HHI) for two new liquefied natural gas carriers (LNGCs) to be built at HHI’s shipyard in Ulsan for SK Shipping, a Korean shipowner. Delivery is scheduled in 2019. The vessels, designed according to the new IGC standards published in 2016, will be equipped with GTT's Mark III Flex membrane technology. Mark III Flex is particularly well-suited for the highly efficient XDF propulsion system installed on SK Shipping's LNG carriers, as the technology offers a high level of insulation performance. “GTT is very pleased to continue our collaboration with HHI. This new contract demonstrates HHI's confidence in GTT technologies which already equip some fifty LNG carriers in service built by the shipyard…

LR Establishes New Notion for LFPF

Lloyd’s Register (LR) has developed a new notation for low-flashpoint fuels (LFPF), allowing owners and shipyards to demonstrate that their design and construction meet requirements.The notation will come into effect as of January 1, 2016, as part of LR’s and Regulations. In the last 12 months, the industry experienced two major changes in legislation with the revised International Code for the Construction and Equipment of Ships Carrying Liquefied Gases in Bulk (IGC Code) and the adoption of the International Code of Safety for Ships using Gases or other Low-flashpoint Fuels (IGF Code). The codes have broadened the horizons for gas applications…

Bestobell Bags HHI's Valve Order

Bestobell Marine, a world leading supplier of cryogenic valves for ships, has won a major new order from Hyundai Heavy Industries (HHI) in South Korea to supply valves for two new vessels. Bestobell’s Globe and Check valves will be used within vessels being manufactured for Greek shipowner, Gaslog. This latest order is the result of a number of years of product development by Bestobell Marine to provide flanged Globe and Check valves to meet HHI’s unique specification. This involved a great deal of innovation to create new patterns and tooling for casting and machining the valve bodies, working closely with HHI’s design department. The contract also involved the design and approval of a new smaller version of Bestobell Marine’s unique FLIV (float level isolation) valve.

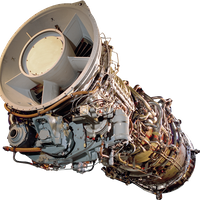

GE Contracted to Service Australian Navy Frigates

GE has signed an in-service support contract with the Australian Defense Materiel Organization’s Maritime Cross-Platform Systems Program Office. Under the contract, GE will provide maintenance and logistic support services for the Royal Australian Navy’s (RAN) GE LM2500 aeroderivative marine gas turbines that power Adelaide- and ANZAC-class frigates. GE will be backed by GE Marine and Air New Zealand Gas Turbines for this multi-year contract. In addition to repair and overhaul of the RAN’s 16 LM2500s and associated accessories…

Alfa Laval Expands LNG Solutions Portfolio

Alfa Laval has entered into a patent license agreement with Daewoo Shipbuilding & Marine Engineering (DSME) for the use of DSME’s patents on high pressure fuel gas supply systems. The agreement signed in March 2015 enables Alfa Laval to further develop the Alfa Laval Fuel Conditioning Modules for use with high pressure gas injection engine technology from MAN Diesel & Turbo. The agreement will see Alfa Laval use DSME patents with Alfa Laval Fuel Conditioning Modules for use on natural gas-powered ships, such as LNG carriers.

Bestobell Extends Valve Range

Bestobell Marine, part of the President Engineering Group Ltd. now offers both butt weld and flanged connections for all its Globe and Check valves. These valves range from small (DN15) to large (DN350). Valves with flanged connections are particularly in demand with the Japanese and Korean shipbuilding companies, as they are designed for ease of installation premised by less welding. To make the product development process quicker and more efficient, Bestobell Marine used a 3D modeling program…

Caterpillar Sponsors 2014 High Horsepower Summit

Caterpillar Inc. now underway in New Orleans, Louisiana. The event is North America’s leading conference on the use of natural gas to fuel high horsepower operations. As an industry leader in the design and manufacture of dual-fuel and natural gas engines, Caterpillar plans to highlight its commitment to delivering the highest customer value for energy and power systems operations, as well as rail, marine and mining applications. “We’re proud of where our natural gas heritage has brought us today and excited to lead the next wave of natural gas products and services taking shape in the industry,” said Caterpillar Vice President with responsibility for the Large Power Systems Division Tana Utley, who will present the keynote address at the Summit.

Bestobell to Extend Valve Choice to Customers

Bestobell Marine, part of the President Engineering Group Ltd, has innovated within its range, which means it can now offer both butt weld and flanged connections for all its Globe and Check valves. These valves range from small (DN15) to large (DN350), allowing Bestobell Marine to offer greater flexibility to its customers. Valves with flanged connections are particularly in demand with the Japanese and Korean shipbuilding companies, as they are easier to install and involve less welding.

Seaborne Ethane and Demand for a New Ship Type

Lloyd's Register report looks at the commercial landscape, regulatory issues and technical realities of a new trade in ethane emerging as a result of increased U.S. U.S. ethane production capability, as a byproduct of total increased U.S. gas production, is underutilized. The potential exists for annual exports of 1 million metric tons of ethane to provide employment for 0.18 million cubic meters of shipping capacity if shipped to North Europe, a further 0.32 Mn Cu M if shipped to South Asia and a similar amount to China through the Panama Canal.

DNV GL Initiative For Acceptance Of Ultrasonic Flow Meters For Wet Gas

DNV GL has initiated a joint industry project (JIP) to promote the use of multi-phase ultrasonic flow meters for wet-gas applications. Seven industry partners have committed to the JIP, but it is open for more partners. Currently, multi-phase flow meters and wet-gas flow meters are used for both topside and subsea measurements, enabling operators to improve reservoir modeling and management, optimize production, and manage flow assurance. The output of wet-gas flow meters is also used to determine sales allocation between E&P companies and the royalties payable to the host government. The technology has been used for dry-gas metering over the last decades, and the first results under wet-gas conditions are promising. However, there is no systematic approach to its use for wet gas.

Bioremediation Goes Mainstream

A reliable solution for response and prevention that can save money, time and regulatory aggravation is here. The threat of oil pollution has long been a problem in the shipping community. You don’t have to look too far to review the myriad of oil spills that have plagued the industry. The Exxon Valdez spill that occurred 25 years ago has recently come to the forefront once again as there is evidence that the ramifications of the spill are still being felt in the fragile eco-system of several Alaska beaches.