Kanfer, CGR Partner to Market LNG Bunkering Vessels

Kanfer Shipping AS, the Norway-based shipping company focused on liquefied natural gas (LNG) break-bulk and bunkering ships, said it has entered into an exclusive agreement with CGR Arctic Marine (CGR), the Norwegian LNG technology company that has designed and developed a unique LNG bunkering vessel as well as an innovative gas delivery system that together reduce the overall cost of LNG bunkering infrastructure.Under the licensing and development agreement, Kanfer will exclusively…

Alfa Laval, MAN Energy Solutions Join Forces

In partnership with MAN Energy Solutions, the Alfa Laval Fuel Conditioning Module (FCM) LPG has undergone successful tests with the first two-stroke, high-pressure marine engine to use LPG as fuel – and has been evaluated for use with ammonia."As the marine industry embraces a growing range of alternative fuels, including LPG and ammonia, Alfa Laval is committed to providing the advanced fuel systems needed for engine protection and efficiency," said a press release.The competitiveness of LPG as a fuel is increasing. Not only does LPG virtually eliminate sulphur emissions, it has a lower cost than many other fuels and is easily available worldwide.

IMO 2020, IoT & the Enviro Agenda

While conservatism is a hallmark of maritime, research from Inmarsat finds that IoT may be helping turn the tech tide by delivering new solutions that ease rather than complicate compliance.With environmental imperatives mounting, shipping’s hesitation concerning new technology has been laid bare in an Inmarsat Research Program report that includes data on how far the industry sees IoT-based solutions as a gateway to sustainability. Directly out the porthole is the IMO 2020 fuel sulfur cap, but further along is 2050 the target to cut GHG ship emissions by 2050.

Senex Energy Gemba Tests Successful

Australian energy company Senex Energy has successfully tested a gas exploration well in the Cooper Basin in South Australia.According to the Brisbane-based company The Gemba-1 well flowed 227,000 cubic metres (8 mcf) of gas per day over a period of a week."Senex Energy has successfully completed the initial flow test of the Gemba-1 gas exploration well in the Cooper Basin, with stabilised flow rates of approximately eight million standard cubic feet per day, plus associated liquids," said a stock exchange annoucement.Senex Managing Director and CEO Ian Davies said: “Senex is delivering on its strategy to become a material supplier of gas to the east coast market, and this Cooper Basin gas discovery adds another potential supply source from our growing portfolio.

Statoil Acquires 25% Stake in Brazil's Roncador

Statoil ASA and Petróleo Brasileiro S.A. (Petrobras) have agreed that Statoil will acquire a 25 percent interest in Roncador, a large oil field in the Campos Basin in Brazil. The transaction nearly triples Statoil’s production in Brazil, with attractive break-evens and potential for additional value creation for both parties through the application of Statoil’s expertise in improved oil recovery (IOR). The total consideration comprises an initial payment of $2.35 billion, plus additional contingent payments of up to $550 million. “This transaction adds material and attractive long-term production to our international portfolio, further strengthening the position of Brazil as a core area for Statoil.

Construction Begins on Johan Sverdrup Riser platform

The riser platform construction start was marked today at the Samsung Heavy Industries yard in South Korea. Project director for Johan Sverdrup Kjetel Digre (from right), project manager for the riser platform and the processing platform Ståle Nordal and head of Samsung Heavy Industries’ offshore division Younsang Won led the formal celebration of the construction start in South Korea 30 June. “As we are starting the riser platform construction we are taking another important step in delivering the Johan Sverdrup project on schedule,” says project director for Johan Sverdrup Kjetel Digre. The preparations for the riser platform construction started already in January 2015…

Aker, Fjords Join Forces

Aker Solutions and Fjords Processing have formed an alliance to develop technology and capabilities for advanced, cost-effective wellstream separation and treatment solutions for the subsea and topside oil and gas industry. The WellSep alliance will apply Aker Solutions' subsea processing experience and testing facilities and Fjords' topside and onshore separation technologies to provide complete solutions. "This is a great opportunity to further develop our key technologies with one of our most important partners, Aker Solutions," said Rune Fantoft, chief executive officer of Fjords Processing. "The alliance will further strengthen our wellstream separation technology portfolio, testing and in-house capabilities," said Alan Brunnen, head of subsea at Aker Solutions.

A Boost for UK Offshore Drilling? DW Monday Muses

Drilling activity offshore UK is now expected to increase over the next few years as government and industry reacts to the recommendations in Sir Ian Wood’s report – the “Wood Review” – to maximise UK offshore oil & gas recovery advises Douglas Westwood's 'DW Monday' study. From a peak of 396 in 1996, numbers of wells drilled offshore UK fell to 164 in 2013, a low not seen since 1979. Development wells were down from 289 in 1998 to 120 in 2013. Exploration & appraisal drilling, on which offshore production ultimately depends, saw numbers fall from 224 in 1990 to 44 last year. Of these the key driver is of course exploration wells, down from 157 in 1990 to just 15 last year.

Wood Review Aims to End Squabbles in UK's North Sea

By John Kemp. The opinions expressed here are those of the author, a columnist for Reuters. Britain's North Sea exploration and production business is set to be transformed, with cooperation replacing competition and proactive, intrusive regulation replacing a light touch. On Monday, ministers promised to back fully the recommendations contained in Ian Wood's review on maximising oil and gas recovery from the UK Continental Shelf (www.woodreview.co.uk). A powerful new regulator will be spun out of Britain's Department of Energy and Climate Change (DECC), staffed by industry experts with salaries to match, to end the squabbling among offshore operators and promote a strategy based on shared infrastructure and regional development plans.

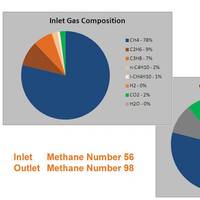

Making Flare Gas Useful

Wärtsilä has developed the GasReformer, a product which converts associated gas, which is often flared, into usable fuel for its dual-fuel engines. When producing oil, associated gas is also released from the deposits. In many places this gas is commonly burnt off in gas flares, a waste of energy and a pollutant of the atmosphere. In addition to useful methane, this gas consists of heavier hydrocarbons including ethane, propane and butane. The composition of the gas typically also vary during the production phase of the oil field.

Don Rodocker: The Man in the Sea

In the early days of subsea technology, there were a number of pioneers: men and women who stepped over the edge of what we knew about the underwater world. These individuals left the comfort of solid ground to explore beneath the waves and report back to the rest of us what they had seen. They pushed boundaries, raised the stakes and in some instances opened our minds to the possibilities. They were subsea visionaries. Today, those boundaries continue to be pushed, and undersea technology, now more than ever, is reaching new heights.

Siemens Subsea Products Adopts All-Electric Tube Bending

Siemens Subsea Products has chosen an all-electric tube bender from Unison to improve the quality and speed the production of the small-bore hydraulic tubes it uses on subsea hydraulic flying leads with Multiple Quick Connections (MQC), Cobra Heads and associated offshore oil and gas recovery equipment. The tubes feature complex bends of extremely high accuracy, and until now the company has either fabricated them manually or bought them in as pre-formed sub-assemblies. Siemens Subsea Products produces a wide range of subsea electric…

World Fleet Set to Change: DNV's Shipping 2020 Scenario

DNV’s Shipping 2020 scenario explores technology uptake based on market forces, regulatory changes, fuel prices, technology costs & specific shipowner requirements. Based on expected market developments, regulatory changes, fuel prices, cost and availability of new technology and specific shipowner requirements, the model explores the technologies with the best payoff that will also ensure compliance with the relevant environmental requirements. Economic power is shifting to Asia, impacting trade routes and the demand for vessels.

Aker Wins Statoil Subsea Trees Contract

Aker Solutions to supply Statoil with subsea trees & control modules for the Visund Field on the Norwegian continental shelf. The contract is for the supply of five subsea trees and eleven control modules, and is valued at aproximately NOK 300-million. Visund is an oil and gas field located 22 kilometres north-east of the Gullfaks field in the Tampen area of the Norwegian North Sea. The field came on stream in the spring of 1999. The five subsea trees for the Visund field will be equipped with Aker Solutions' most advanced subsea technology. This technology enables oil and gas production from intelligent wells which provides higher oil and gas recovery and more reservoir data.

Aker Solutions & Statoil awarded ONS Innovation Award

Aker Solutions & Statoil have been awarded the ONS Innovation Award for the Åsgard subsea gas compression system. Reservoir pressure in producing gas fields falls over time, causing gas output to decline. For production to continue and maximise recovery from the fields, gas pressure must be raised or production will cease. Until now the solution has been to install gas compressors on an existing platform, or to build a new manned compression platform. A more cost-effective alternative is to install the compressors on the seabed…

Wärtsilä Hamworthy Get Petrobras Flare Gas Recovery Contract

The units, each of which will be able to handle 150,000bpd, are to be deployed on the pre-salt fields, off Santos, Brazil. Three of the FPSOs will be utilised for Block BM-S-11 Lula (Tupi) and one will go to Block BM-S-9 Guara. "We have developed a strong position in the growing market for flare gas recovery as offshore operators seek greater efficiency over increasing environmental concerns due to flaring," said Hamilton Santos, Project Manager, Gas Recovery Business Unit, Hamworthy Oil & Gas Systems. "Flaring gas has a global impact on climate change by adding about 400 million tons of CO2 in annual emissions. The contract underscores…

Wärtsilä Hamworthy Wins Petrobras Contract

Wärtsilä Hamworthy has won a contract to supply its Flare Gas Recovery packages to four floating production, storage and offloading (FPSO) units under construction for Petrobras. The units, each of which will be able to handle 150,000bpd, are to be deployed on the pre-salt fields, off Santos, Brazil. Three of the FPSOs will be utilised for Block BM-S-11 Lula (Tupi) and one will go to Block BM-S-9 Guara. “We have developed a strong position in the growing market for flare gas recovery as offshore operators seek greater efficiency over increasing environmental concerns due to flaring…

Hamworthy to Open New Service Center in Brazil

International fluid handling specialist Hamworthy is to open a new dedicated service centre in Brazil. The new service center represents a direct investment in a market that has offered sustained growth for the company’s oil and gas handling systems and pump systems businesses in recent years. With offices in Rio and planned workshops and warehousing operations in Macae it will support customers through easy access to spare parts from a domestic warehouse and qualified service personnel for all Hamworthy products, as well as related products and equipment installed onboard. The service centre will also offer assistance to domestic yards during the installation and commission stages of construction.

Hamworthy Supports Brazilian Offshore Finds

Hamworthy, the international fluid handling specialist, is highlighting its commitment to Brazil’s growing marine and offshore sectors in the run up to opening its first dedicated service centre in Brazil in 2011. Hamworthy’s commitment to offer strong technological solutions at competitive prices and to seek local product content has been strongly rewarded through a series of high profile orders for oil and gas handling systems. Hamworthy has an established presence in Brazil, offering products and services through its local agency, Tridente since the 1970s. Hamworthy Oil & Gas Systems was recently awarded a major contract by Brazilian…

Hays Awarded Statoil Research Prize

Professor Curtis Hays Whitson has been awarded Statoil’s research prize 2010 for his major input to boosting knowledge about recovery of gas and gas condensate fields and improved recovery of oil fields by the use of gas injection. The prominent researcher came to Norway in the early 1980s. As professor and entrepreneur he has conducted numerous studies for Hydro and Statoil in connection with field implementation of gas injection on the Norwegian continental shelf (NCS) and internationally, as well as studies related to gas field recovery and phase behaviour of reservoirs.

Hamworthy Supports Brazilian Offshore Oil & Gas Finds

Hamworthy Oil & Gas Systems was recently awarded a major contract by Brazilian shipyard Estaleiro Promar SA for the design and supply of cargo handling systems for eight liquefied petroleum gas (LPG) carriers destined for operation by Transpetro, a subsidiary of Petrobras. The vessels will be designed by Hamworthy’s specialist naval architecture consultancy in Poland, along with the cargo tanks and cargo handling system. In 2007 the Oil & Gas Systems business secured an order for its regasification technology onboard the floating storage regasification unit (FSRU) Golar Winter. Located in Guanabara Bay in Rio de Janeiro, the vessel has an important role in supplying gas to the Rio de Janeiro area.

Norsk Hydro Begins Exploration Using SGI Technology

Norsk Hydro ASA selected SGItechnology to expand its national and international oil exploration efforts as well as for a number of research projects. To perform seismic acoustic tomography and migration velocity analysis to determine optimal oil well drilling sites, Norsk Hydro's facility in Bergen, Norway, selected a large, shared-memory SGI Altix system. For its research center in the port city of Porsgrunn, Norsk Hydro acquired an SGI Altix for computational fluid dynamics applications and a Silicon Graphics Prism visualization system. Norsk Hydro's research center in Bergen is developing and testing different methods of imaging and working on a large variety of technical services for oil and gas production.

Aker Kvaerner Launches IOR Tool

Aker Kvaerner Launches the PodEx - a new, technology solution to the ever-growing challenge of maximizing oil and gas recovery from mature subsea fields. The PodEx is a module that integrates new functionality and instrumentation directly into the existing subsea control system. It is a cost-effective alternative that requires very little installation time. Its ultimate aim is to optimize production at brownfield developments and enhance environmental safety. The PodEx utilizes spare subsea electrical circuitry or co-existent power supplies to convey increased well and reservoir data to topside data acquisition systems for analysis. It is scalable and offers a transparent communication layer which is adaptable to any subsea application.