Nippon Paint Marine Launches New Antifouling

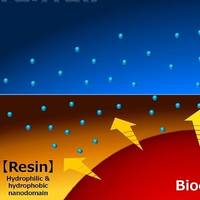

Coatings manufacturer Nippon Paint Marine has launched a new antifouling technology engineered to enhance antifouling performance while improving the time and the film thickness required for application.Introduced to the market this week, FASTAR is a self-polishing antifouling paint that incorporates a unique nano-domain resin structure designed to minimize the effect that seawater temperatures, vessel speeds and other external factors have on coating performance.It is by precisely…

Shipyard Coatings: Green is the Best Color

VT Halter’s new state-of-the-art blast and paint facility, already paying dividends for the shipyard’s bottom line and the environment alike, is poised to lift your bottom line with improved coatings and reduced corrosion.When it comes to marine coatings, preparation is everything. If that’s the case, then Gulf Coast-based VT Halter has all the boxes checked when it come to making sure that every vessel component and exposed surface that leaves its facility is ready for whatever harsh conditions come next. That’s because, in April of 2018, VT Halter Marine unveiled a state-of-the-art blast and paint facility that today allow ship sections to be prepared, blasted and painted in a controlled environment.

Marine Coatings Evolve for the Better

Innovation and new technology continue to shape the marine coatings market. A narrowing field of global coatings manufacturers offer new products while improving existing ones to meet customer demand. Ultimately, customer demand, along with environmental compliance pressures are all driving the marine coatings industry as ship owners, operators and shipyards alike seek better products. Customer demands are often related to cost and efficiency. Costs – and the list is a long one – include not just product cost…

Hull Medic: Keep Coats Efficient

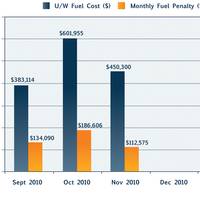

Is it possible to calculate the degree to which fouling and corrosion hinder a vessel’s efficiency? Can a ship operator use that data to determine the best time to clean or recoat the hull of his/her ship? Macsea’s answer to both questions: yes. The marine technology specialist has developed a solution called Hull Medic which they say measures the effects of hull fouling on a ship’s performance. Using a ship’s propeller as a power absorption measuring instrument, the fully automated Hull Medic estimates both water speed and shaft power.

Jotun Profits Remain Satisfactory

Jotun expects the difficult global economy to continue to have a greater impact. When compared with the record level of 2008, the figures in the first eight months of 2009 are still satisfactory. In litres and kilos the group sold one per cent less paint than it did for the same period last year. There are market-related variations in the group. Jotun continues to have growth, including in China, South Korea and key markets in the Middle East. A weak development has taken place in many parts of Europe, including Norway. In the first eight months of 2009 the operating profit was NOK 858 million, compared with NOK 807 million in the same period in 2008. Operating income amounted to $1.3b compared to $1.1b last year.

Carnival Uses Intersleek 900

International Paint completed a hull coating project on Carnival Cruise Line’s Carnival Victory. The seven-year-old Italian-built vessel, one of a fleet of 23 passenger liners, was coated with Intersleek 900 during a recent drydocking in the Grand Bahamas Shipyard in Freeport, Grand Bahama, in late 2007. Carnival Valor is was due to be coated with Intersleek 900 in early 2008. Intersleek 900 was chosen following a long evaluation of the Intersleek 700 foul release system by Carnival Cruise Lines.