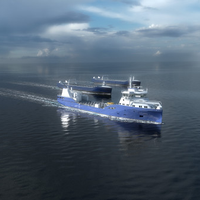

Ulstein Introduces New Subsea Vessel for Offshore Energy Market

Norwegian shipbuilder and ship designer Ulstein has developed a new subsea vessel - ULSTEIN SX232 – designed to service the offshore wind market for floating and fixed installations as well as offshore oil and gas industry.Designed for walk-to-work operations in the offshore energy market, the ULSTEIN SX232 features an optimizes hull based on the ULSTEIN TWIN X-STERN design.The vessel is equipped with smart power and propulsion system developed to minimize energy consumption during DP operations and an integrated energy recovery system utilizing all the waste heat in the machinery systems…

Barge Completes Autonomous Navigation Test in Busy Belgian Waterways

Kongsberg Maritime said Friday it had completed a live trial of autonomous shipping technology in Bornem, Belgium, demonstrating the company's progress in fully autonomous systems.The test vessel, Zulu 4, an inland waterway barge owned by Blue Line Logistics NV, is equipped for remote-operated and autonomous transport demonstrations for the AUTOSHIP project, which is part of Horizon 2020, an EU research program.As part of the test, Zulu 4 maneuvered and navigated on unrestricted waterways, and it demonstrated berthing and unberthing capability.

Cargo Vessel Completes Complex Autonomous Journey Off Coast of Norway

Norway's Kongsberg Maritime said Friday it had successfully demonstrated a range of remote and autonomous technologies on a cargo vessel operating off the coast of Norway.The test cruise has been named one of the most complex autonomous journeys at sea so far, Kongsberg Maritime said.The Eidsvaag Pioner is one of the two vessels that are equipped for remote-operated and autonomous transport demonstrations for the AUTOSHIP project, which is part of Horizon 2020, an EU research program.Owned by the Eidsvaag shipping company…

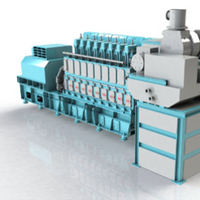

ClassNK Grants AiP for Dual Fuel Generator Engine Using Hydrogen Gas as Fuel

Japanese ship classification society ClassNK has granted an Approval in Principle (AiP) for a dual fuel generator engine using hydrogen gas as fuel and related machinery systems and arrangements for a 160,000m3 liquefied hydrogen carrier developed by Kawasaki Heavy Industries, Ltd. (KHI). This marks ClassNK's first AiP for a dual fuel generator engine using hydrogen gas as fuel.As hydrogen is expected to be used as a clean energy source to realize a decarbonized society, ClassNK…

New Product: SeaQ Remote for Autonomous Ship Ops

As the move toward advanced remote and autonomous operation of vessels proceeds at speed, Vard Electro introduced SeaQ Remote to facilitate a new generation of larger robotic vessels.The new product, which will see its debut delivery on a total of 14 newbuild marine robotic vessels contracted with shipbuilder VARD, is designed to unify the SeaQ suite of automation systems into a single user interface with the full range of remote functionality from shore.“We are now investing heavily in autonomous technology and digitalization…

Partnering on the Digital Ship: Inside Denmark’s ShippingLab

When will the first fully digitized, autonomous and environmentally friendly ship be ready to sail? The answer is uncertain but the Danish Maritime Authority’s ShippingLab project aims to have most of the technical and managerial challenges solved in as little as two years from now. Tom Mulligan reports.Denmark’s ShippingLab project is a three-year initiative that commenced its work in March 2019 with the aim of developing the first fully commercially operational, fully digital, autonomous and environmentally friendly ship.

World First: Cruise Ship Piloted Remotely During Sea Trials

Royal Caribbean's Silversea Cruises says it is preparing to take delivery of its newest ship, Silver Origin, following a unique set of COVID-19-related challenges overcome by the shipbuilder and innovative sea trials that included world-first remote operations.The new 100-passenger ultra-luxury cruise ship was built by Dutch shipyard De Hoop, which completed construction despite setbacks brought on by the coronavirus pandemic.Silver Origin was still under construction on March 15…

Penflex Receives DNV GL Certification

Flexible metal hose manufacturer Penflex Corporation said Penflex Vietnam has received DNV GL certification for its products used in marine and offshore applications.Penflex single and double braided 700 Series sizes 2 ½” to 12” and P3 Series sizes ¼” to 2” comply with all DNV GL standards pertaining to metal hose.DNV GL rules for classification: Ships Pt. 4 Ch. 6 Piping SystemsDNV GL offshore standards (OS): DNVGL-OS-D101 Marine machinery systems and equipmentDNV GL class programmes…

Kongsberg to Test Autonomous Ship Technology

Norwegian technology firm Kongsberg announced it will install and test autonomous ship technologies on two vessels in Europe's inland waterways and short sea coastal shipping routes.The AUTOSHIP project will aim to test and further develop key technology linked to fully autonomous navigation systems, intelligent machinery systems, self-diagnostics, prognostics and operation scheduling, as well as communication technology enabling a prominent level of cyber security and integrating the vessels into upgraded e-infrastructure…

Quality is the Buzz Word for ECGS

Those shipowners looking to install marine exhaust gas cleaning systems (EGCS) as way of meeting global sulfur cap requirements are advised to ensure that manufacturers, shipyards and installers are using quality, high-end materials.Based on the collective experience gained from more than 1500 EGCS installations, Clean Shipping Alliance (CSA) 2020 members found the quality of materials and coatings used is the most important factor in optimizing EGCS safety and averting any corrosion problems during operation.“There are always some challenges involved when specifying ships’ machinery systems and scrubbers are no different,” said Arne Hubregtse, Executive Board Member, Spliethoff.

"A Maritime Disaster Waiting to Happen"

Since the founding in 2016, cyber defence company Naval Dome has won awards for its Endpoint cyber defense system and achieved the highest level of security certification from classification society DNV GL, helping to protect merchant ships, cruise ships and yachts from cyber-attack.In 2019, Naval Dome optimized Endpoint with a “Dashboard” App, providing maritime users with a clear picture of the cyber status of all critical systems on board the ship, designed to allow users…

ROMAS Project Completes First Phase

The Norwegian Maritime Authority (NMA), Høglund, the marine solutions and system integration company, ferry operator Fjord1, and the classification society DNV GL have completed the first testing phase of the ROMAS (Remote Operation of Machinery and Automation Systems) project.As ship systems become more complex, operators increasingly rely on the suppliers of individual systems to operate and maintain them. At the same time, finding machinery engineers who have the skills to deal with these sophisticated systems and are willing to work on board for weeks or even months is challenging.One way of dealing with this is through remote operations.

Across the Big Pond: Metal Shark Expands Again

Metal Shark Expands Internationally with New Croatia Engineering Facility.Shipbuilder Metal Shark has established a foothold across the Atlantic with the opening of a dedicated European engineering office.Metal Shark’s first location outside of the United States, “Metal Shark Croatia” is a new engineering facility recently opened in the city of Rijeka on Croatia’s northern Adriatic coast.The facility currently employs nearly 20 naval architects, machinery systems engineers, and…

Exploring Class Approvals, Supported by CAD

ABS software supports designs across most vessel sectors. This pilot project focused on tug and barge designs, producing promising results.Jensen Maritime, the naval architecture and marine engineering arm of Crowley Maritime Corp, and ABS have completed a precedent-setting pilot project using three-dimensional computer-aided design (CAD) models to support plan reviews for class approval.In what is believed to be an industry first, the innovative pilot was not proprietary to specific brands of CAD software, allowing designers to use the versions with which they are most familiar, or those that are best suited to the design project.Saving Time and MoneyIn eliminating the need to create 2D drawings to submit for the class design-review process…

Workboat Design: Interview with Bob Hill

Robert (Bob) Hill of Ocean Tug & Barge Engineering Corp., of Milford, MA has specialized in the design of AT/B’s for many years. As probably the world's most experienced designer of large articulated tug/barge (AT/B) systems, Hill’s success comes, in part, from a willingness to innovate. Ocean Tug & Barge Engineering Corporation and Robert Hill are the co-inventors of the Intercon Connection System. In a nutshell, his firm has had a hand in over 70% of the operational AT/B’s in service in America – including, 80% of those built or converted since 1994.

Rolls-Royce Inks Largest Ever Fishing Vessel Contract

Rolls-Royce Marine said it has signed a contract with Thoma-Sea Marine Constructors, L.L.C. in Louisiana for the development of a 100-meter-long trawler to be built for the Seattle based company Arctic Storm Management Group, LLC.In addition to being the largest fishing vessel contract to date for Rolls-Royce with a value of about £15 million, it also marks the first Rolls-Royce fishing vessel concept to be built at a U.S. shipyard.Rolls-Royce has been working closely with the owner…

Rolls-Royce to Design and Power Trawler for Prestfjord

Rolls-Royce has received a supply order from Spain’s Astilleros Gondan shipyard for the design, propulsion and auxiliary machinery systems for what has been dubbed one of world’s most advanced fishing vessels.Scheduled for delivery in 2020 to Prestfjord Seafood, a division of Norway’s Holmøy Maritime, the 77m trawler will be based on a Rolls-Royce NVC 732 WP design arranged with triple trawl and pelagic trawl for operation in Arctic waters catching white fish and shrimps. The vessel has been designed to accommodate a 29-person crew.Knut Roald Holmøy…

Marshall Islands to Address Shipping Safety Concerns

The Republic of the Marshall Islands (RMI) has submitted a paper to the International Maritime Organization (IMO) Intersessional Working Group (ISWG) on the consistent implementation of the 2020 global fuel oil sulphur standard under MARPOL Annex VI. The submission, which was co-sponsored by the Republic of Liberia, the Baltic and International Maritime Council (BIMCO), the International Chamber of Shipping (ICS), the International Association of Dry Cargo Shipowners (INTERCARGO), the International Association of Independent Tanker Owners (INTERTANKO), and the World Shipping Council (WSC), is intended to assist the ISWG in developing guidelines on the implementation of regulation 14.1.3 of MARPOL Annex VI.

Valmet to Supply Automation for Icebreaking Tanker

Valmet said it has been awarded a contract to supply automation for an arctic icebreaking tanker to be built by Arctech Helsinki Shipyard Inc. in Finland. The tanker (NB 515) is designed by Arctech and measures 229 m in length and 32.5 m in breadth. It will be built to ice class of Arc 7 and can reliably break ice almost two meters thick. The vessel will be tasked with transporting gas condensate year-round from the Yamal Peninsula to Europe and Asia, able to operate independently in the demanding ice conditions of the Northern Sea Route.

Leadership Changes at Newport News Shipbuilding

Huntington Ingalls Industries (HII) announced several leadership changes at the company’s Newport News Shipbuilding division. Lucas Hicks has been promoted to vice president of construction for the aircraft carrier John F. Kennedy (CVN 79), and Charles Southall has been promoted to vice president of engineering and design. Southall succeeds Jennifer Boykin, who previously served in the role before being named president of Newport News Shipbuilding. Mike Shawcross, who currently serves as Newport News’ vice president…

Odd Lundberg Chooses Rapp Marine Winches

Rapp Marine said it has received a new order from Odd Lundberg As, marking the third generation of owners from the shipping company who have selected its deck machinery. “This is the first time the shipping company has selected a high-tech electrical solution,” confirms Morten Stenkjær, VP Sales at Rapp Marine AS. “The owner’s new pride is a combined ring-net and pelagic trawler and will be equipped with a complete electric deck machinery solution from Rapp Marine. Mats Lundberg…

IoT & Changing Connectivity at Sea

Whether it’s autonomous cars or connected houses, it seems like everywhere you look these days, internet of things (IoT) technology is a focus. Even in the conservative maritime world, IoT is currently a hot topic. Shifting supply chain solutions and business models are fundamentally changing the way that commercial shipping and the wider transport sector operates. IoT enables an organization to capture value from information, regardless of sector, and in essence forms a loop that creates a larger process. Deloitte conceptualized this process and named it the Information Value Loop in 2015.

Navigating the New Norm

It is not business as usual in the world where we do business. Things are changing. Even regulations themselves are changing from less prescriptive in nature to more performance-based. As Chairman, President and CEO of a global classification and technology-centric company that operates in 70 countries with 5,000 employees, I am continually assessing the impact of these changes on the capabilities ABS needs to fulfill its mission and maintain its leadership position in the maritime, offshore and government industries it serves. To know where we are heading, we have to know where we began.