NASA Welding Technologies Could Revolutionize Workboat Fabrication

Solid-State Welding Processes Being Developed for NASA Manufacturing Programs Could Significantly Reduce Workboat Fabrication CostsWhether it is for a tug boat, cargo vessel, or an offshore supply ship, much of the workboat fabrication industry is located along the Southern Coast of the U.S. But a visit to any one of the workboat facilities in that area (or any other in the country) would reveal antiquated and archaic fabrication processes used seventy years ago. The workboat manufacturing process is very expensive, labor intensive, and has not really changed since World War II.

ABB WinsTunisia's Gas Treatment Plant Bid

ABB, the leading power and automation technology group, has been awarded a $216 million contract to deliver a gas treatment plant to the South Tunisian Gas Project (STGP).The order was awarded by OMV Tunisie Production GmbH, a subsidiary of Austrian energy group OMV, and was booked in the third quarter. ABB will be responsible for the turnkey delivery of the Nawara gas treatment plant (GTP) including gas separation and Liquefied Petroleum Gas (LPG) extraction units. It will also provide key automation, communications and power components, including the control system and transformers and switchgear for the electrification of the plant.

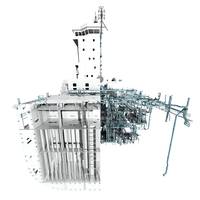

Design’s Future 3D Modeling, Virtual Reality Wave of Design Future

Rooted in early computer-aided design (CAD) and manufacturing applications, design and construction software is firmly at the helm of most shipyards today, enabling the production of better designed, more efficient and consistently built ships produced with measurably less waste: less waste of time, materials, man hours and most important, money. The ROI can be substantial, and is traceable throughout the entire process, across all sub sectors such as project management, purchasing, materials, labor and build sequencing.