Hepburn and Sons Joins Forces with MELD Manufacturing

Hepburn and Sons LLC announced it has officially joined forces with MELD Manufacturing Corporation, developer of the patented, solid-state metal additive manufacturing process and provider of MELD 3D printing machines. The companies have been working together since 2021 to introduce the Navy and other military services and DoD agencies to MELD, also known as additive friction stir deposition.Hepburn and Sons LLC is a small business founded in 2010 whose initial focus was to provide expert consulting…

ABS Approves 3D Printed Spare Parts After Tanker Trial

Parts fabricated by additive manufacturing (AM) – also known as 3D printing – and installed on an oil tanker for operational testing have been validated to be in good working condition, marking a significant step for the technology's implementation in the marine industry.The project involving ABS, ConocoPhillips Polar Tankers, Sembcorp Marine Ltd and 3D Metalforge started in February 2021 with the fabrication and lab-testing of functional additive manufactured parts, which were then installed on board the oil tanker Polar Endeavour.

World First: Patrol Vessels Deploy 3D Printers

3D printing technology developed in Darwin will be deployed by the Royal Australian Navy in a world-first trial that will streamline the maintenance of patrol vessels.The Morrison Government will invest $1.5 million in the two-year Supersonic Deposition 3D printer pilot, which will lead to a significant increase of parts availability compared to what the regular supply chain can provide.Minister for Defense Industry, the Hon Melissa Price MP, congratulated the Charles Darwin University’s Advanced Manufacturing Alliance, along with industry partner SPEE3D, for producing the cutting edge and uniquely Australian capability.“This high-tech machinery enables metal components to be produced quickly and efficiently…

Hamadyk Named Chair of NSRP Board

NSRP is a national collaboration of private shipbuilders that provides framework to improve shipbuilding processes. NSRP focuses on national shipbuilding and naval practices to improve the efficiency of the U.S. shipbuilding and ship repair industry.Hamadyk, who has worked for Newport News for 38 years, was instrumental in collaborating with the U.S. Navy and industry partners on the technical standards that led to the adoption of additive manufacturing of metal components for nuclear-powered warships. The first 3D part certified for use was installed on the aircraft carrier USS Harry S.

Alfa Laval PureSOx Scrubber Systems – 10 Years at Sea

The arrival of 2019 leaves just one year until the global sulphur cap becomes reality. But as the marine industry scrambles to ready itself, an important milestone has already been reached. The new year marks a decade since the first vessel set sail with an Alfa Laval PureSOx scrubber on board.In 2009, the RoRo vessel DFDS Ficaria Seaways entered dry dock for an expansion of its cargo space. While the vessel was being rebuilt, a hybrid PureSOx system – able to perform closed-loop as well as open-loop scrubbing – was retrofitted to clean the exhaust gas from its 21 MW main engine.

Next Generation of Corrosion Inhibiting Fuel Additives

Cortec has developed the next generation of VpCI fuel additives for more potent corrosion protection of fuel systems. Cortec VpCI-707 has been specially formulated to protect fuel tanks and systems from corrosion and sludge formation without damaging copper and aluminum. It is an option for keeping new and existing fuel tanks and systems in good condition during day-to-day operation and especially during vulnerable times such as intermittent operation, storage, or shipment. Other benefits of VpCI-707 are its improved water handling and good injector-cleaning capabilities.

Paving the Way for 3D Printing in Naval Shipbuilding

A U.S. shipbuilder’s piloting of new technologies is redefining the future of the naval engineering and shipbuilding industries.Huntington Ingalls Industries’ (HII) Newport News Shipbuilding division, in collaboration with the U.S. Navy, has led the adoption of additive manufacturing of metal components for nuclear-powered warships as part of HII’s digital transformation.This technological development will result in the first certified 3-D-printed metal part—a prototype piping assembly—being installed on the aircraft carrier USS Harry S. Truman (CVN 75) early next year.

New Sealing System for Multi-cable Transits

Transits with large cable assemblies often look like a plate of spaghetti. The huge number of cables does not only make the transit confusing but it is virtually impossible to expand the cable assembly. BEELE Engineering changes all this with its CONTROFIL transit system. The system enables the orderly and controlled transit of large numbers of cables, while simplifying future expansion of the cable assembly.The CONTROFIL system was initially developed for a leading train manufacturer, as a fire-resistant and maintenance and service-friendly solution for trains.

Malcolm Elected to General Dynamics Board

The board of directors of General Dynamics has elected Mark Malcolm to be a director of the corporation, effective August 5, 2015. He has been appointed to serve on the Audit Committee. Malcolm is the president and chief executive officer of Tower International, Inc. (NYSE: TOWR), a position he has held since August 2007. Tower International is one of the largest independent global suppliers of engineered automotive structural metal components and assemblies for major vehicle manufacturers. Previously Malcolm worked for Ford Motor Company for 28 years, with his final position as executive vice president and controller of Ford Credit, from 2004 to 2005.

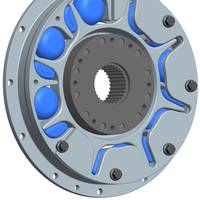

New Propulsion Couplings to Launch at Workboat

Renold Hi-Tec Couplings, of Halifax, U.K., will debut a new range of high temperature, marine propulsion rubber-in-compression couplings on booth 3809 at the International Workboat Show in New Orleans from December 3-5, 2014. The new HTB-MP range is a second generation of couplings based on the existing HTB-GS range. According to the manufacturer, the intrinsically fail-safe nature of rubber-in-compression couplings ensures continuous operation and avoids the loss of drive that could be experienced with other coupling types as a result of failure.

Stauff Clamps Allow Multilevel Installation

Stauff ACT clamps are a solution for the installation of pipework in applications where efficient protection against corrosion is essential. The development of crevice corrosion on pipelines – a known and documented problem in the oil and gas industry – can be prevented long-term. This solution also generates enormous savings potential, thanks to extended maintenance and service intervals. The combined usage of specially designed SIG safety locking plates and AF stacking bolts…

Passively-cooled Cabinets on World’s Largest Vessel

Enclosure specialist Intertec is supplying high performance environmental protection cabinets for Shell’s Prelude floating liquefied natural gas project. Designed specifically for extended service life in hazardous areas, the shelters incorporate innovative semi-passive cooling technology and are some of the most stringently specified instrumentation protection solutions that Intertec has ever produced. Shell’s Prelude floating liquefied natural gas (FLNG) project is setting new engineering records.

DSC, Port of New Orleans Recognized

DSC and its customer, the Port of New Orleans, were recently recognized in the 2011 Hot-Dip Galvanizing Excellence Awards for use of galvanized steel throughout the dredge design. The Dredge Edward S. “Ned” Reed was awarded in the water and marine category of the annual competition, representing the finest achievements in the use of hot-dip galvanizing. For each award, all parties involved in the project are recognized winners, as the nature of galvanizing is collaborative, and the final project reflects the work of many.

DSC and Port of New Orleans Recognized for Industry Award

DSC and its customer, the Port of New Orleans, were recently recognized in the 2011 Hot-Dip Galvanizing Excellence Awards for use of galvanized steel throughout the dredge design. The Dredge Edward S. “Ned” Reed was awarded in the water and marine category of the annual competition, representing the finest achievements in the use of hot-dip galvanizing. For each award, all parties involved in the project are recognized winners, as the nature of galvanizing is collaborative, and the final project reflects the work of many.

118-ft. Yacht Designed to Travel to 70 Knots

Three Vericor Power Systems' TF50 marine aeroderivative gas turbines have been selected to power the 118 Wallypower high-speed yacht being built by Intermarine Shipyard, Sarzana, Italy for Wally Yacht. This is Wally Yacht's first foray into high-speed power yachts, and the company's initial application of gas turbines. Wally Yacht, based in Monte Carlo, Monaco, is a world-renowned designer of high-speed sailing and power yachts. The 118-ft. yacht will feature three TF50 gas turbines in a Combined Diesel Or Gas (CODOG) turbine configuration. Two TF50s will be used as side or "wing" engines, with one small auxiliary diesel engine connected to each wing engine. The diesels will provide for very slow maneuvering only.

Odense Steel Shipyard Ltd. sells Balti ES Ltd. to Cargotec Corporation

Odense Steel Shipyard Ltd. (Odense Staalskibsværft A/S) announces the sale of Balti ES Ltd., a manufacturer of metal components based in Narva, Estonia, to Cargotec Corporation, Finland. The final company transfer is expected to take place within 1-2 months. Following the closure of Maersk Container Industri´s production facilities in Tinglev, Denmark the strategic importance of Balti ES for the Odense Steel Shipyard Group has been reduced. Balti ES functions as a separate unit and today sells most of its production capacity to companies outside the A.P. Moller - Maersk Group. Balti ES was acquired by the Odense Steel Shipyard Group in 1997, and currently employs approximately 600 people. The two parties have agreed not to disclose the purchase price.