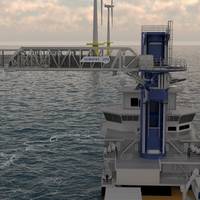

Ulmatec to Deliver Gangway for Another Jones Act Offshore Wind Vessel

Norway-based gangway supplier Ulmatec has secured a contract to supply a 32-meter motion-compensated gangway and logistics support systems for the next US-built Jones Act service operation vessel.This 260-foot vessel will be built for Edison Chouest Offshore (ECO) by North American Shipbuilding, an ECO affiliate. The vessel is a sister design to the “ECO Edison,” the first U.S.-built Jones Act service operation vessel (SOV), and will feature spacious cabins and facilities for 60 technicians. It will serve the growing offshore wind industry in the U.S.

Ulmatec's Gangway for First Jones Act-compliant Service Operation Vessel

Norway-based gangway supplier Ulmatec has secured a contract for the supply of a 32-meter motion compensated gangway and logistics support systems for ECO Edison, the first U.S.-built Jones Act service operation vessel (SOV). This 260-foot vessel will be built for Edison Chouest Offshore (ECO) by North American Shipbuilding, an ECO affiliate, and will be able to accommodate 60 technicians. Once complete, the vessel will immediately provide operational support out of Port Jefferson…

Chouest's LaShip Shipyard Adds New Welding Robot

Finnish welding and production automation company Pemamek said it delivered a new welding robot station to Edison Chouest Offshore's (ECO) LaShip shipyard in Louisiana.The newly commissioned PEMA VRWP-C robot station is a compact solution to automatize micro panel welding, but also other small-to-medium-sized constructions. The system is based on PEMA WeldControl 200 which enables easy weld path creation and robot programming.“The beauty of the PEMA VRWP-C is that it is fast to commission and easy for the customer to learn to use it…

Shipbuilding: Seaspan Shipyards & Building Canada’s Future

There’s a shipbuilding resurgence underway in Canada that’s being driven by a long-term multibillion dollar government initiative to rebuild the federal fleet of Royal Canadian Navy and the Canadian Coast Guard vessels and breathe new life into the country’s shipbuilding industry. Seaspan’s Vancouver Shipyards is an active player.Under Canada’s National Shipbuilding Strategy (NSS), the Vancouver, B.C. shipbuilder was selected in 2011 to deliver several types of large non-combat vessels for the Navy and Coast Guard…

From Across the Big Pond

With familiar faces, new partnerships and Houston office, Damen widens its North American profile with a flurry of new work orders. With a flourish and a flurry of new business, Damen’s new U.S.-based office officially opened in Houston, Texas on July 1, 2016. Registered as Damen Area Support North America BV Co., it has been established to provide a local presence and work hand-in-hand with the North American market, offering a full range of ready built, standard and custom design vessels as well as the products and services of Damen Shipyards group ‘License to Build’ program.

ECO Orders Rolls-Royce Equipment for New AHTS

Rolls-Royce has been awarded a contract worth $30.6m with the American owner Edison Chouest Offshore (ECO). The contract for ship equipment comprises Azimuth main propulsion, propulsion control systems, anchor winches and an anchor handling crane for an Anchor Handling Tug Supply vessel (AHTS). The contract also includes an option for equipment for a second vessel of similar type. The vessel is designed by ECO’s North American Shipbuilding and will be built to Polar Class 3, equipped to operate in arctic waters with air temperature down to minus 40 degrees Celsius.

Energy Markets Buoy U.S. Shipbuilding

Proliferation of energy related transport continues to drive commercial U.S. As the United States aims towards energy independence by the end of this decade, domestic shipyards and vessels owners are reaping rewards from this most unexpected turn of events. Hydraulic Fracturing, or fracking, has been the main (and well publicized) culprit in the rapid turn of events. While the proliferation of gas has been widely known for years, the presence of oil, in quantity, was a pleasant…

Top Marine Vessel Operators Overcome Challenges

U.S. marine vessel operators have invested in their fleets, adopted new technologies and switched to cleaner burning engines and fuels to stay in business. In this edition, we take a look at how industry leading marine operators have flourished, sometimes in tough circumstances. At family-run McAllister and Chouest, sons and daughters learned operations from the ground up, while CEO Todd Hornbeck revamped the first version of a company started by his dad. All value their employees and say workplace safety is a priority. Each of these companies is quick to meet customer demands.

Arctic Energy Exploration Efforts Heat Up

Oil and gas—and also mining—are the drivers today propelling Arctic maritime operations and the construction of new vessels able to operate in extreme latitudes. While the gas and oil resources can be recovered in the Arctic or far north and shipped to markets by sea or pipeline, the cost of doing must be balanced upon the global market price for those commodities. Ships and marine structures able to operate in the harsh conditions of the extreme latitudes require special designs and construction techniques.

Nupas-Cadmatic Signs Software Contract with NAS

Nupas-Cadmatic has signed a deal with North American Shipbuilding (NAS), part of Edison Chouest Offshore and based in Larose, Louisiana. The contract includes the complete configuration of more than 50 structural, outfitting, electrical, production and nesting licenses. The deal was signed after a trial period that challenged the software’s capabilities. The test showed that Nupas-Cadmatic provides the yard with a wide range of benefits not covered by their former CAD/CAM software. nupas-cadmatic.com ncg.nl

Edison Chouest Offshore Ordering New Vessels, Expanding Terminals

The Edison Chouest Offshore (ECO) global family of companies, plans to enlarge its fleet and expand its terminal facilities in support of its customer base. The Chouest newbuild order book contains over 40 vessels, a vast majority to be constructed at its four U.S.-affiliate shipyards: North American Shipbuilding (Larose, LA), LaShip (Houma, LA), Gulf Ship (Gulfport, MS) and Tampa Ship (Tampa, FL), as well as its Brazilian shipyard, Navship. ECO’s worldwide fleet now approaches 250 highly specialized offshore service and support vessels.

ECO to Add 40-Plus Vessels, Expand Port Facilities

The Edison Chouest Offshore (ECO) global family of companies announced plans to enlarge its fleet and expand its terminal facilities in support of its customer base. The Chouest newbuild order book contains more than 40 vessels, a vast majority to be constructed at its four U.S.-affiliate shipyards: North American Shipbuilding (Larose, La.), LaShip (Houma, La.), Gulf Ship (Gulfport, Miss.) and Tampa Ship (Tampa, Fla.), as well as its Brazilian shipyard, Navship. ECO’s worldwide fleet now approaches 250 highly specialized offshore service and support vessels. The largest portion of the newbuild program contains 17 vessels, with options for an additional 20, in a new class of 312’ x 66’ x 26’ new generation, clean design, diesel-electric platform supply vessels (PSV).

Guarded Optimism for 2013 from U.S. Gulf Boatbuilders

Caveats and some doubts remain. Marine companies along the Gulf of Mexico will be busy in 2013 producing offshore vessels to meet expected growth in the region’s deepwater drilling sector over the next several years. Vessel repairs will be active too. Worker training will be stepped up to address a skilled labor shortage. And nearly three years after BP’s spill off coastal Louisiana, safety will remain a priority. But with the nation teetering on a fiscal cliff – which may spur tax increases and government spending cuts – demand for official and military vessels could be affected…

Jensen Hires Naval Architect, Seek Execs

Scott Ward has joined Jensen Maritime Consultants as a naval architect in the company’s new office in the New Orleans business district. Ward comes to Jensen with a wide variety of experience in design review, project management and operations. Before joining Jensen he worked at American Bureau of Shipping (ABS), a provider of marine and offshore classification services, in the machinery and hull departments. He has also worked for North American Shipbuilding as a naval architect and at Pacific-Gulf Marine as an assistant technical superintendent.

Big Ideas Sometimes Come in Small Packages

Hyde Marine’s chemical-free, IMO Type Approved ballast water treatment solution packs performance in a smaller footprint. That’s good news for small vessel operators who may soon find themselves impacted by a problem that previously was thought to be a “bluewater” issue. The notion that ballast water treatment and invasive species are both strictly the domain of big, bluewater liners coming from the Far East and other exotic locales quickly went out the porthole last November when the Environmental Protection Agency (EPA) issued its long-awaited, updated draft Vessel General Permit (VGP) rule. The new rules potentially bring regulations to bear on vessels as small as 79 feet LOA and others, depending on service and routing.

Arctic Oil Exploration: Shell Awaits New Giant Icebreaker

The M/V Aiviq icebreaker, contracted by Shell Oil to support drilling in Alaska’s Chukchi Sea, is scheduled to be completed by Louisiana-based Edison Chouest Offshore in early 2012. The vessel, ordered in July 2009, is on track for April 1, 2012, delivery in Galliano, La., and will then head north, according to Shell Oil spokesman Curtis Smith. The $200m Aiviq is the largest vessel ever built by Chouest, and will be among the most advanced and powerful, non-military icebreakers on the waters.

Offshore: Baker Hughes Awards EBDG Contract

Seattle-based Elliott Bay Design Group, through its New Orleans office, was selected by Baker Hughes to provide the owner's design of the Blue Tarpon a state-of-the-art well stimulation vessel. EBDG was contracted to integrate Baker Hughes' stimulation equipment into a hull under construction at North American Shipbuilding in Larose, LA. The Blue Tarpon was delivered in Houston on June 9. Working with Baker Hughes, EBDG's team designed the vessel to provide high-rate and high-volume stimulation treatments for demanding offshore operations.

Chouest Purchases Tampa Shipyard

On November 18, 2008, Edison Chouest Offshore officials appeared before the Tampa Port Authority in an effort to secure the assignment of Tampa Bay Shipbuilding and Repair’s long-term lease agreement with the port. The authority had no objection to the transfer and, on that date, Tampa Ship, LLC was born. Chouest assumed management and operation of the yard in early December. The Tampa shipyard is a full service conversion, overhaul and repair facility that was previously owned by a group associated with Mobile, AL-based Bender Shipbuilding and Repair.

Bay-Houston Towing Buys Tractor Tug

Bay-Houston Towing Co. announced that it has purchased the tractor tug C-TRACTOR 1 from Alpha Marine Services. The tug, which will be renamed the WILLIAM M, will be based in Corpus Christi, TX. The WILLIAM M is a true tractor design, with the Ulstein drive units located forward. This allows the twin EMD 16-645 engines to generate 110,000 pounds of bollard pull both ahead and astern. Her design speed is 12 kts. The WILLIAM M is 102’ long, has a beam of 37’, and a working draft of 17’. The tug was built in 1989 at North American Shipbuilding. The WILLIAM M has considerable fire fighting capability. It can pump 3500 gallons per minute through fore and aft fire fighting monitors.

U.S. Shipyard Design Enhancement Project Gets NSRP Funding

The development of key features in ShipConstructor will be funded by the Second-Tier Shipyard Design Enhancement Project II, which recently received significant funding from the National Shipbuilding Research Program (NSRP) Advanced Shipbuilding Enterprise. The project, headed by Bender Shipbuilding & Repair Co., Inc., includes seven shipyards and four naval architect firms, representing the core of second-tier shipbuilding and ship design in the United States. The overall goal of the project is to provide U.S. second-tier shipyards with a state-of-the-art design system that will enhance their global competitiveness. Albacore Research Ltd. (ARL) will extend ShipConstructor’s capabilities to fully meet the design requirements of the U.S. second-tier shipyard industry.

ECO Expands Aggressive Newbuild Campaign

Edison Chouest Offshore (ECO) announced plans to build several new anchor handling towing supply vessels (AHTS), as well as more than a dozen new generation 280-ft. platform supply vessels (PSV) in its affiliated shipyards in the U.S. All vessels are scheduled to join the ECO domestic fleet within the next three years. Construction highlights feature seven new anchor handlers: Two (2) 348-ft., 21,600 HP new generation anchor handlers and five (5) 288-ft., 16,000 HP vessels. Also slated for construction are fourteen (14) 4,700 deadweight ton PSVs. All the vessels are slated for delivery between February 2007 and mid-2010, and will be constructed at ECO affiliated shipyards: North American Shipbuilding (NAS) in Larose…

Shipbuilding CEO takes SCIA’s top honor

According to reports, Gary Chouest was honored with the South Central Industrial Association’s award Thursday night. As president and CEO of Edison Chouest Offshore, Gary Chouest’s leadership has grown the two-vessel shrimping operation founded in 1960 by his father into a worldwide company whose more than 130 vessels are well recognized, SCIA President Chet Morrison told the crowd of about 400 gathered at Cypress Columns Wednesday night. The vessels, all built and owned by Edison Chouest Offshore, are designed for its client-companies’ needs. Most are built at its North American Shipbuilding facility in Larose, but also at North American Fabricators in Houma.

The Efficient Tugboat: Efficienty of a Different Type: Laney Chouest

When it comes to large tugs, none is larger than the Laney Chouest, the world's largest anchor handling tug supply (AHTS) vessel. At 348- x 72- x 31-ft., the Laney Chouest is the king of all tugs in the Gulf of Mexico, or anywhere else for that matter. It was built by the North American Shipbuilding, Larose, La. a part of Edison Chouest Offshore, Galliano, La. who also owns and operates the vessel. The vessel is super efficient since it is designed to do several jobs that formerly needed separate vessels For example, the vessel will set suction piles that anchor floating oil production facilities to the seabed using the largest tow winch every built. That is a huge job for any anchor handler.