NSF Certification for PPG's Products, Coating Systems

PPG Industries’ protective and marine coatings (PMC) business announced that four individual coatings and primers and two combined coating-and-primer systems have been certified by NSF International for water-tank applications. AMERCOAT 133/844 pit-filler is a hand-applied coating designed to fill deep holes in pitted steel surfaces with a single pass. It features a 100-percent solids formulation and emits almost zero volatile organic compounds (VOCs), and it trowels easily to a smooth finish. SIGMAWELD 199 primer is a weldable preconstruction primer that provides up to 12 months of corrosion protection during construction and offers extended recoatability thereafter.

Vigor Completes Conversion of Barge Klamath

Vigor Marine, a Vigor Industrial subsidiary, recently completed work on Barge Klamath, converting the vessel from a petroleum tank barge to an OSVR measuring 350’ x 76’ x 22’. The barge is owned by Crowley and leased to Shell as part of its comprehensive Alaskan oil spill response fleet in the Beaufort and Chuckchi seas. “Vigor’s extensive expertise in ice classing vessels for arctic waters, combined with the geographic proximity of their facilities, has made them a strong partner for Shell’s planned offshore operations in Alaska,” said Curtis Smith, spokesman for Shell Alaska.

Huntington Risks Losing $194 Million on Carrier’s Overrun

Huntington Ingalls Industries Inc. stands to loss as much as $194.3 million, more than 40 percent of its potential fee, under the Navy’s latest estimate of overruns for the USS Gerald R. Ford aircraft carrier, according to Bloomberg. Construction of the Ford, the Navy’s most expensive warship, is likely to exceed by $884 million the shipbuilder’s target contract cost of about $5.2 billion for detailed design and construction, according to Navy officials and the service’s Selected Acquisition Report, obtained after it was delivered to Congress on March 29. The Ford is intended to be the first in a $40 billion, three-ship class of carriers. Its rising costs have brought questions from Republican Senator John McCain about the Navy program and the shipbuilder’s performance.

BAE Systems and Moran Iron Works Join Forces on Fabrication

Mobile, Alabama – BAE Systems Southeast Shipyards and Moran Iron Works Inc. signed a teaming agreement in order to collaborate on the pursuit of plate steel fabrication projects for industrial plant customers. Together, they will serve customers throughout the northern and southern regions of central and eastern North America. With access to the Great Lakes, Moran Iron Works is able to reach customers throughout the Midwest and Northeast regions of the United States and Canada, providing fully integrated and outfitted steel platework assemblies and modules ready to install at their industrial sites. BAE Systems Southeast Shipyards has facilities located in Mobile…

USACE Completes Dredge Hurley Extension

The Corps of Engineers Memphis District Ensley Engineer Yard (EEY), in partnership with the Corps of Engineers Marine Design Center (MDC) in Philadelphia, Pa., completed the lengthening of the Dredge Hurley by 48-feet. The project increased the dredge’s length from 305 to 353 feet, making it one of the largest vessels on the river and increased the dredge’s dredging depth from 40 to a maximum of 75 feet. This project will enable the Corps’ newest dustpan dredge to be better serve…

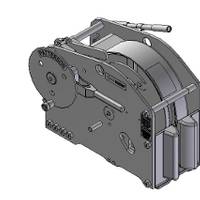

Barge Innovations: The Yo Yo Winch

The new Yo Yo Winch, using technology from WW Patterson Company of Pittsburgh, is designed to prevent two of the most dangerous and unstable conditions in a deck-hand’s life: the snarling bird’s nest of tangled rope or wire that results when lines gets kinked or snagged, and the threat of injury from snapped cables. WW Patterson Company reported that field testing of the Yo Yo Winch produced evidence that the design is 75 percent more efficient than traditional ratchets for making up and breaking tow.

Intracoastal Producing More Push Boats

Joey Portier shows the donut welded in place to protect the stern bearing on the Jackie Gonsoulin. Joey Portier, yard manager at Intracoastal Iron Works, Inc, carries a lot of construction details for the yard?s 72 by 30-foot push boat in his head. Asked about shafting details on the two that they are currently building for Lebeouf Bros. Towing, he explains that they are 19 feet long. The six-inch shafts swell to seven inches after the journal is installed. The journal is a piece…

A Step Forward For Thick Section Plate Cutting

For years, general manufacturing companies have enjoyed the benefit of laser cutting systems for producing complex or simple parts in batch volumes as low as one, and as high as tens of thousands. The laser is an incredibly powerful tool that remains unsurpassed in manufacturing activities across the world. As flexible and reconfigurable production tool that provides welding, cutting and machining capabilities in a single device, lasers are readily automated and have demonstrated that they can easily operate in "lights-out" mode for even greater productivity. With all this said, why aren't there any laser shipyards? Why hasn't one of the worlds largest and most important transportation industries rushed to implement laser cutting and welding technology?

Flexible Membrane Covers and Seals Damages

The Gulf Responder is a 45-ft. aluminum catamaran designed to operate in oil and hazardous chemical spills. Currently under construction at Scully's Fabricating in Louisiana, the vessel's expected delivery date will be either late January or early February. The 15-ton vessel is powered by twin turbo diesel engines with water jet propulsion and equipped with two 1,000 lb. MagnaPatch devices. The MagnaPatch is a patented pollution abatement device. The device is a self-propelled, flexible, magnetic membrane that covers and seals the damages on oil and chemical bulk carrier hulls. Spanning 100 sq. ft. in total area, the MagnaPatch is 10 times larger than most hull penetrations. Weighing more than 1,000 lbs., the MagnaPatch is powerful enough to pick up a small car.