Wärtsilä to Supply Scrubbers for Trasmed GLE S.L. RoPax Pair

Wärtsilä Exhaust Treatment will install its open loop exhaust gas abatement technology on two roll-on/roll-off passenger ferries owned by Spanish company Trasmed GLE S.L., which is part of the multinational logistics company Grimaldi Group.Trasmed GLE S.L. has selected four of Wärtsilä’s I-SOx open loop scrubbers with exhaust de-plume systems for the RoPax vessels Volcan del Teide and Ciudad de Granada, which operate in the Mediterranean Sea. Each vessel will have four scrubbers installed, one on each main engine.

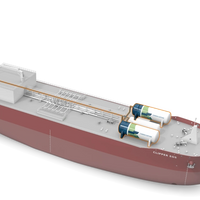

Solvang Ethylene Carrier to Be Retrofitted with CCS System

Norwegian shipping company Solvang will pilot a retrofitted carbon capture and storage (CCS) system on one of its ethylene carriers in an effort to test the technology as a potential solution to support decarbonization in the shipping industry.Wärtsilä Exhaust Treatment said it is designing the retrofitted unit while it also completes a land-based 1MW test system at its Moss headquarters in Norway. The land-based unit will be completed in Autumn 2021, and the companies expect to retrofit the pilot CCS system on Solvang's 21…

Wärtsilä to Test Marine Scrubbers for Carbon Capture

Wärtsilä Exhaust Treatment said exhaust gas abatement systems, also known as scrubbers, may soon be used to directly tackle maritime carbon dioxide (CO2) emissions as technology advances enable manufacturers to design and upgrade scrubbers to capture carbon at the point of exhaust.Wärtsilä said it has found carbon capture and storage (CCS) can be developed and scaled for ships, and that the solution is technically viable for the sector to pursue among a range of solutions helping to drive decarbonization in shipping…

Wärtsilä to Supply Scrubbers to NCL

European technology giant Wärtsilä will be supplying hybrid scrubber system packages for Norwegian Cruise Line's (NCL) Norwegian Breakaway and Norwegian Getaway.According to a press note from Wärtsilä, the scrubber systems have been ‘specially customized to meet the specific needs’ of the two cruise ships – which included adapting ‘to meet the ships’ restricted space availability’.The scrubber systems will enable the 325 meters long cruise vessels to be in compliance with the International Maritime Organization’s (IMO) sulfur restriction legislation while operating on heavy fuel oil (HFO). The legislation became effective in January 2020.

Scrubbers 'No Silver Bullet' for Shipping -Wartsila

Global shipping fleet must cut sulfur emissions by 2020. Wartsila received record orders for sulfur scrubbers last year. Shipping industry hopes that so-called sulfur scrubbers are a quick-fix solution to compliance with drastic emissions reduction demanded by 2020 are somewhat misguided, one of the world's biggest manufacturers of the equipment told Reuters. The International Maritime Organization's (IMO) cut to the amount of sulfur the world's fleet can emit will have massive implications for shippers, oil refiners and even crude oil producers.

Wärtsilä Scrubbers for New Japanese Bulk Carriers

Wärtsilä informs it has been contracted to supply exhaust gas cleaning systems for two new 56,000 DWT Handymax bulk carriers being built at Oshima Shipbuilding Co., Ltd. in Japan for Tokyo based NYK Bulk & Projects Carriers Ltd. (NYK BP). The newbuilds will be the first vessels owned or chartered by NYK Group having exhaust gas cleaning systems installed. By fitting the scrubber systems, the ships will be compliant with the International Maritime Organization’s (IMO) SOx emissions regulations, which come into force in 2020.

Wärtsilä Scrubbers for Korean Ferry Newbuild

Wärtsilä said it has been contracted to supply its exhaust gas cleaning system for a new Korean ferry being built for Weidong Ferry at the Hyundai Mipo Dockyard. The system will consist of two 13 MW Open Loop V-SOx Scrubbers specifically optimized for the new vessel, a 31,000 gross tonnage RoPax ferry to be operated by Weidong Ferry between Korea and China. The contract with Wärtsilä, which was booked in January 2017, will see the first Wärtsilä scrubber system installed where the shipyard, the owners and the vessel's operational area are all in Korea.

Wärtsilä Hybrid Scrubbers for 3 Box Ships

Wärtsilä has received an order for Hybrid Scrubber Systems to clean the exhaust emissions from three 2,500 TEU container vessels. The installation has been ordered by a major European owner and operator and will be carried out at the Jinhai Heavy Industry Co., Ltd in China. The contract was signed in March 2015 and the systems are scheduled for delivery in December 2015. The scrubber system, which comprises two scrubber units, will be installed to clean the exhaust from both the main and auxiliary engines. This arrangement enables great flexibility and cost savings when operating at different operational settings. In all, 28 MW of total power output will be handled by the Wärtsilä system. The system is designed to clean the sulphur oxide (SOx) and particulates from the exhaust gas.

Wärtsilä Launches Inline Scrubber System

Wärtsilä said its new inline scrubber system is designed to offer notable benefits over conventional exhaust gas cleaning systems, and its compact form saves considerable space, which is particularly important in smaller vessels and when being retrofitted, while the lower cost structure of the new design offers CAPEX advantages. With just one scrubber system per engine, installation is faster and easier, Wärtsilä said, which consequently reduces the out-of-service time for the vessel. Operational flexibility is also improved.

Hamworthy Krystallon, HHI Contract for Scrubber System

Solvang ASA, through Hyundai Heavy Industries, orders system for 84,000 cbm LPG carrier as three-year countdown to 2015 ECA approaches. Hamworthy Krystallon, the leading marine scrubbing technology manufacturer, today signed a significant contract with Hyundai Heavy Industries (HHI), the world's biggest shipyard. The contract will see Hamworthy Krystallon deliver a scrubber system on a Liquified Petroleum Gas tanker being constructed for Solvang ASA. The 84.000 cubic meter (cbm) VLGC will have the worldʼs first full vessel scrubber system. The newbuild vessel will be fitted with two scrubbers; one for the main engine and one combined scrubber for three auxiliary engines. The scrubbers and washwater treatment will be situated in the funnel, in a modular design.

Ship Emissions First: Commercial Scrubber System in Operation

Hamworthy Krystallon announced that the first of four vessels installed with the company’s seawater scrubbers for Italian ship owner Ignazio Messina & Co has come on line. Linea Messina is reported to be the first ever vessel to operate commercially with a scrubber system, enabling Ignazio Messina to meet 0.1% sulfer emissions regulations in EU ports, as well as “future-proofing” the vessel for the impending 2015 0.1% Emission Control Area (ECA). “This is a landmark moment, not just for Hamworthy Krystallon, but the entire shipping industry,” said Sigurd Jenssen, Managing Director, Hamworthy Krystallon. “Bringing Linea Messina on line highlights the validity of scrubbing technology as a viable and cost-effective solution to meet the stringent sulphur emissions regulations…

Hamworthy Acquires Krystallon

Hamworthy has completed the acquisition of Krystallon Limited. Fluid handling systems supplier Hamworthy has acquired the company that pioneered gas scrubber development as a commercially viable alternative to costly low sulphur content distillates, to comply with new International Maritime Organization (IMO) MARPOL Annex VI regulations on emissions. Last year IMO agreed the concept of Emission Control Areas, ruling that the maximum sulphur content in fuels used in such zones must be cut to 1.5%, then to 1% by 2012, and to 0.1% in 2015. The regulations are already in force in the North Sea, English Channel and the Baltic. Similarly the US and Canada have applied for ECA status for the waters extending 200 Nm from their coasts. Other countries are expected to follow suit.