BHGI Hires Naval Achitect Delaney

Bristol, R.I.-based naval architecture and marine engineering firm Bristol Harbor Group, Inc. (BHGI) announced it has hired Braden Delaney, as a naval architect. He graduated from the University of Michigan in Ann Arbor, Mich. with an B.S.E. in naval architecture and marine engineering.Prior to joining BHGI, Delaney interned at NASSCO and NAVSEA, providing engineering support for shipyard operations in addition to interning as a salvage naval architect. Delaney is also a member of the Society of Naval Architects and Marine Engineers (SNAME).

Mobile Analysis: 3D, 2D CAD Viewer "to go"

The CoreTechnologie 3D Analyzer Viewer is now available through a mobile license-lending feature.The powerful 3D Analyzer Viewer of the German-French software manufacturer CoreTechnologie (CT) comprises in the current version 4.3 anew license-borrowing function that allows to use the software for a limited time for example on a laptop. Already the inexpensive basic version of 3D Analyzer includes 24 different interface formats, such as CATIA V5/V6, NX, Inventor SolidWorks, Creo, STEP, JT as well as FBX and OBJ.

INSIGHTS: Metal Shark's Chris Allard

A naval architect and graduate of the Webb Institute, Co-Owner/CEO Chris Allard introduced the engineering-centric approach that has fueled Metal Shark’s growth; driving innovation and transforming the company from a regional builder to a globally recognized industry leader.A member of the ownership team since 2005, Mr. Allard has overseen the expansion of Metal Shark from several employees to over 350. Under Mr. Allard’s direction, Metal Shark has successfully captured over $500…

Cast Polyurethane for High Impact, High Wear Applications

Although ship and boat building design engineers have traditionally specified parts made of rubber, plastic or steel when durability is required, many are considering cast polyurethanes as a new alternative for demanding, high-wear, abrasion and impact applications. Cast polyurethanes, also broadly referred to as urethanes, are tough, elastic materials that combine many of the performance advantages of high-tech plastics, metals and ceramics along with the resiliency and flexibility of rubber parts and are ideal for ship/boat building components.

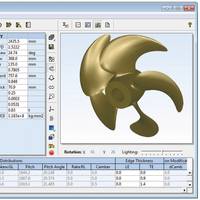

Overcoming the Propeller Supply Bottleneck

Hydrocomp’s ProCad facilitates in-house Process Control of Propeller Design and Manufacture. Maritime Tactical Systems Inc. (MARTAC) is a Florida-based company building next-generation unmanned vessels for military applications. In preparation for the “Rim of the Pacific” (RIMPAC) military exercises in Pearl Harbor this last July, MARTAC needed a new propeller design for their MANTAS series high-speed vessels. Unfortunately, their current supplier was not meeting delivery schedules for the high-quality surface-piercing propellers that they need…

WPT Power Appoints Engineering Manager

Robert De Hoyos has joined WPT Power Corporation as the company’s new engineering manager, bringing to the post 21 years of manufacturing experience as a mechanical engineer. De Hoyos’ expertise is in new product design, drawing and routing as well as traditional engineering department functions. He has taught mechanical design (Solidworks and Auto CAD) classes at Midwestern State University and training courses in geometric dimensioning and tolerancing (GD&T). Most recently, he was a mechanical engineer for Magic Aire, United Electric Company. Prior to that, he was chief engineer at Washex Manufacturing overseeing production and R&D design projects.

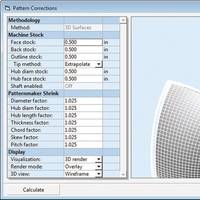

Propellers: One Size and Shape Does Not Fit All

Hydrocomp’s newest release of PropCad incorporates 3 years of enhancements. Propellers are surprisingly complex devices, especially considering most are a solid piece of metal with no moving parts. The variation in vessels and operational requirements leads to wildly different designs, from noise-sensitive propellers for luxury cruiseliners to wide-blade sets for tugs. With different combinations of diameters, pitches, blade styles, and blade counts, there is no limit to the design alternatives available.

All-electric Tube Benders Take a Step Forward

The tube bending machine innovator Unison said it is moving the technology forward again, with the completion of a groundbreaking all-electric machine that is capable of bending tubes and pipes up to 9 inches/225 mm in diameter. The availability of all-electric machines at this new size level brings the benefits of instant set-up and right-first-time precision bending to many new applications in sectors including shipbuilding, powergen and oil, gas and chemical processing. According to Unison…

FEA Aids Deepwater Horizon Failure Forensics

On the evening of April 20, 2010, Deepwater Horizon suffered a blowout while drilling in the Macondo Prospect, an area in the Gulf of Mexico 40 miles off the southeast coast of Louisiana. The platform caught fire; two days later, it sank. Numerous attempts were made to seal the well, but oil continued to spew into the Gulf until July 15, when a temporary cap was put in place. Relief wells then pumped concrete into the area underneath the wellhead, and the well was deemed permanently sealed in mid-September.

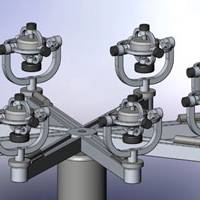

APR Labs Greener Method of Propulsion

In 2006, Aries Propulsion Research Labs (APR Labs) introduced a new method of propulsion technology labeled Omni-Directional Propulsion (ODP). The method was created by designer Chris B. Hewatt and was first published on the United States Patent and Trade Organization (USPTO) Web site as publication 20060230847. APR Labs says that this unique design has been gaining attention in the transportation industry, but could have its greatest impact on the marine industry because it creates movement without propellers.

Ellicott Dredges Federal Expansion Grant

The U.S. Department of Transportation (Maritime Administration) has announced that Ellicott Dredges, LLC of Baltimore, Md. has won a grant for $1.75m to help finance capacity expansion for manufacturing dredgers. Ellicott's project, entitled "Efficient Dredge Building," will create and retain over 20 jobs and will increase Ellicott's crane capacity and modernize its machining capabilities. It will also help pay for modern welding equipment and state-of-the-art IT systems for manufacturing and engineering.

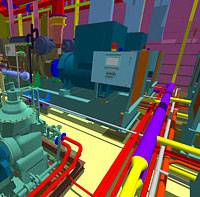

New On-Line Sharing Site for Ship Design

ShipConstructor Software Inc. (SSI), in collaboration with its US-based subsidiary ShipConstructor Software USA, Inc., the National Shipbuilding Research Program (NSRP), and several US shipyards including Northrop Grumman Shipbuilding (NGSB), has reached another milestone in the effort to create further cost savings for their clients. With the introduction of its online sharing site SC4D (http://SC4D.ShipConstructor.com), SSI is now providing the means to create and share 4D outfitting CAD models via the Internet.

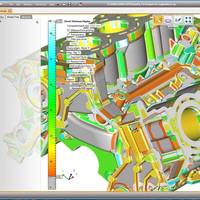

Current Uses of FEA in Shipbuilding

By Tony Abbey, Technical Manager, Noran Engineering, Inc. Finite Element Analysis (FEA) was developed in the Aircraft Industry in the late 1950's as a way of handling the more complex structures that were evolving. Finite Element analysis has been used in the maritime industry for many years. Lloyds Register and other certification authorities were very early adopters of the technique. The NASTRAN FEA code was developed by NASA in the early 1960's to standardize FEA methods across contractors for the major Aerospace projects such as the Moon program and F-111. It was commercialized in the early 1980's. NE NASTRAN was introduced in the mid 1990's with the emphasis on the PC environment to avoid the expense of the mainframe computing bottlenecks that many large contractors were experiencing.

Kvichak Employs SolidWorks

Kvichak Marine Industries of Seattle is using SolidWorks software to design a new 45-ft. Coast Guard patrol boat for a wide range of maritime situations, including search and rescue, environmental protection, law enforcement, and port/coastal security. The company's prototype won the design contract for the boat in a three-vendor competition in 2006. A special provision in the $600m contract requires each of the boat's 5,000 parts to be fully modeled in CAD software. The data will fuel an interactive Web-based assembly that Coast Guard engineers can use in maintaining the boat for decades to come. Kvichak is using SolidWorks custom property capabilities to annotate the Web-based model.