Exploring 'Future Fuels' - Methanol’s Superstorage Solution

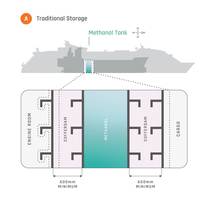

Technical inquiries to SRC Group ramped up after it received Approval in Principle (AIP) for a concept which ‘reinvented methanol fuel storage’ on board ships. Delivering the answers has seen technical talk converting into project discussions ‘Green’ methanol has the ability to one day run vessels almost emission-free, and commercial shipping increasingly investigates. Derived today principally from natural gas, methanol is nonetheless available, relatively easy to handle and predictable.

PPG Wins 5-year Contract from MSC

The global supplier of paints and coatings PPG Industries has been awarded a five-year, $78 million contract by the US Navy Military Sealift Command (MSC) to provide coatings, solvents and technical services to MSC’s fleet of approximately 125 ships.PPG’s global supply and service network will ensure the availability and delivery of a range of coatings and services to Military Sealift Command drydocking facilities around the world, said a press release.Products will include: the PPG PSX brand of polysiloxane coatings, which offer excellent durability and aesthetics for exposed steel surfaces; PPG AMERCOAT 240 epoxy coatings for external surfaces and tanks…

Tech File: An Inside Look at Ballast Tank Linings

The proper lining of ballast tanks is essential and critical to ship safety. Not too many decades ago, ships traveling the North Atlantic routes were experiencing terrible losses from outright sinking in the turbulent seas. It was eventually discovered that the primary culprit was hull failure from ballast tanks rupturing from the inside out due to simple, plain old-fashioned rusting and galvanic corrosion. The U.S. Navy led the way and came up with a recommended formula, or recipe, for a ballast tank coating that paint manufactures could copy in bidding for Navy business.

Ecofix Filler Coat Cuts Rudder Repairs Cost

With an increasing trend for thruster and rudder manufacturers finishing their products with self-cleaning protective hard coatings, Antwerp headquartered Subsea Industries has introduced a filler coating for use with its award-winning Ecoshield hard coat system. Ecofix, specifically formulated to provide shiprepairers and Original Equipment Manufacturers with a cost-effective solution for the repair of corroded or pitted steel surfaces, returns the thruster or rudder to its original state prior to touching up the repaired area with Ecoshield. Boud Van Rompay, Executive Director of Subsea Industries, said: “We are seeing an increasing…

NSF Certification for PPG's Products, Coating Systems

PPG Industries’ protective and marine coatings (PMC) business announced that four individual coatings and primers and two combined coating-and-primer systems have been certified by NSF International for water-tank applications. AMERCOAT 133/844 pit-filler is a hand-applied coating designed to fill deep holes in pitted steel surfaces with a single pass. It features a 100-percent solids formulation and emits almost zero volatile organic compounds (VOCs), and it trowels easily to a smooth finish. SIGMAWELD 199 primer is a weldable preconstruction primer that provides up to 12 months of corrosion protection during construction and offers extended recoatability thereafter.

Sherwin-Williams Awarded for Work on USS Ronald Reagan

Sherwin-Williams said it was awarded Military Coatings Project Award of Excellence for exceptional coatings work on U.S. Navy’s Nimitz-class nuclear-powered supercarrierUSS Ronald Reagan at SSPC 2014. The award recognizes exceptional coatings work performed on U.S. military ships, structures or facilities. “This award is truly an honor for our company in partnership with the U.S. Navy and IMIA,” said Mark Schultz, Marine Project Development Manager, Sherwin-Williams Protective & Marine Coatings.

Hempel Launches New Cargo Hold Coating

Leading coatings manufacturer Hempel announced today the launch of Hempadur Impact 47800, a new dedicated coating for bulk carrier cargo holds. Hempadur Impact offers high-end abrasion, impact and corrosion resistance, and completes Hempel’s range of cargo hold coatings. Hempadur Impact is a new dedicated cargo hold coating for shipowners who want a high-performance cargo hold coating with a very attractive price/performance ratio. The coating protects ship cargo holds from both mechanical damage and the severe abrasion caused when loading hard angular cargoes. With a 7½ year major repair interval, it enables shipowners to extend drydocking periods between major cargo hold coating repairs and so reduce maintenance costs.

Bolidt Underlay Worth Weight for ConocoPhillips

Efforts by ConocoPhillips to achieve the lightest weight possible for the superstructure of its Ekofisk L accommodation facility have been demonstrated by its selection of an underlay construction material. The oil major has selected Boliscreed 400 for the high-profile North Sea unit, which will replace the longstanding Ekofisk H and Ekofisk Q as part of ConocoPhillips plans to prolong activities in the Ekofisk field by up to 40 years. Ekofisk L’s top side is currently under construction at Singapore’s Sembawang (SMOE) shipyard…

Bolidt Underlay Worth Weight for ConocoPhillips

Efforts by ConocoPhillips to achieve the lightest weight possible for the superstructure of its Ekofisk L accommodation facility have been demonstrated by its selection of an underlay construction material which will remain unseen. The oil major has selected BOLISCREED 400 for the high-profile North Sea unit, which will replace the longstanding Ekofisk H and Ekofisk Q as part of ConocoPhillips plans to prolong activities in the Ekofisk field by up to 40 years. Ekofisk L’s topside is currently under construction at Singapore’s Sembawang (SMOE) shipyard…

Euronavy ES301 Surface Tolerant Anticorrosive

Sherwin-Williams offers Euronavy ES301, a solvent-free anticorrosive epoxy designed for application over marginally prepared surfaces. Sherwin-Williams acquired Euronavy in December 2008. “Euronavy ES301 is an extremely durable surface-tolerant coating that allows customers to protect their steel assets against corrosion in an extremely cost-effective way,” said Brad Rossetto, Vice President, Marketing, Sherwin-Williams Protective & Marine Coatings. The product can be applied with no dew point restrictions over damp steel surfaces and over flash-rust, reducing application time and costs. Coating can occur immediately after hydroblasting or other water preparation methods without drying.

60th PSPC Gap Analysis for Chinese Shipyards

Lloyd’s Register Classification Society (China, [LRCS]) and International Paint have delivered their 60th training course aimed at bringing Chinese shipyards up to speed with the International Maritime Organization’s (IMO) new Performance Standard for Protective Coatings (PSPC) on commercial ships. The joint initiative, which ultimately promotes safe and sustainable shipping, has in its first two years re-enforced the reputations of the entities of the Lloyd’s Register Group as the first to provide timely technical advice to industries in the energy and transportation supply chains. Gap analyses, which assess a shipyard’s current coating practices against the new regulatory requirements…

SSPC Publishes Visuals for Waterjetting, Blast Cleaning

SSPC: The Society for Protective Coatings has published two new collections of surface preparation reference photographs: SSPC-VIS 4 and SSPC-VIS 5. SSPC-VIS 4 illustrates the appearances of steel surfaces prepared by waterjetting while SSPC-VIS 5 shows steel surfaces prepared by wet abrasive blast cleaning. Both contain a written guide and explanatory notes, as well as additional photographs that depict degrees of flash rust after cleaning. SSPC-VIS 4 and SSPC-VIS 5 were developed in collaboration with NACE International under the direction of the SSPC/NACE Joint Task Group on Wet Blast Visual Standards. SSPC visual standards and reference photographs are used to access the condition of coated and/or uncoated steel before and after cleaning…

Feature: The Corrosion Control Challenge

Last year Germanischer Lloyd and Mühlhan sponsored a Surface Protection Symposium in October in Lübeck, dealing with the topic of value retention in the shipping industry. The outcome was a lively exchange of ideas among shipowners, coating material manufacturers and surface protection experts. Up-to-date findings from research were discussed with the same vitality as problems from workaday practice. This report provides an overview of the events involved. After Dr. Richter from Germanischer Lloyd had welcomed those attending, Mr. Harms — also from Germanischer Lloyd — described both the development and current status of international stipulations for the assessment of corrosion in water ballast tanks…

The Floating Volvo

Vision, a unique VLCC built by Korea's Hyundai Heavy Industries Co., Ltd. (HHI) in that it features twin-engines and twin-propellers, was recently christened at the Ulsan Shipyard. Concordia Maritime AB's new ultra-large 315,000-dwt VLCC was christened by Mrs. Karen Fidler, wife of the president of Sunoco Inc., the company that chartered the VLCC. Built for Concordia Maritime, of the Stena organization, the VLCC is a revolutionary type of crude oil carrier. The 1,102 ft. (336 m) long Stena V-Max design VLCC differs from other large tankers built in the world to date. In addition to double hulls, the VLCC has double, completely separate engine rooms, double rudders and double propellers.