Corroded Wire Rope Leads to Crane Failure on Bulk Carrier -NTSB

Undetected corrosion and wear led to an equipment failure on a cargo ship while offloading cargo last year in Houston, the National Transportation Safety Board (NTSB) said.On July 23, 2022, the cargo ship Thorco Basilisk was offloading a wind turbine component at the Greensport Terminal on the Houston Ship Channel when the hoisting wire rope on one of the ship’s cargo cranes failed, causing the component to drop onto the vessel’s cargo hold tween deck.No injuries were reported.

Damen Working on New Vessel Class to Support Growing Floating Wind Industry

Dutch firm Damen Shipyards said Tuesday it was working to develop a new class of vessel that will be capable of supporting the growing floating wind industry.Damen has cited forecasts which indicate that by 2050 over 200GW or around 13,500 units of new floating offshore wind turbines will be in operation, and these turbines will be giant, and placed in deeper water than conventional bottom-fixed turbines, requiring chains and anchors of unprecedented sizes. "Even just one installation starting to drag an anchor upwind of others could have a serious impact on the output of an entire wind farm…

Otto Candies Orders FibreTrac Offshore Crane from MacGregor for Wyatt Candies Vessel

Cargotec's subsidiary MacGregor has won a contract with the U.S. offshore support vessel owner Otto Candies to deliver an active heave compensated FibreTrac offshore crane.The order was booked in Cargotec’s 2022 first quarter order intake, with delivery expected to be completed by the end of the year. MacGregor told Offshore Engineer that the crane would be installed aboard the Wyatt Candies dive support vessel.The scope of supply includes full delivery of the 150t AHC crane, rated for the client's needs at 100t lifting capacity, together with Lankhorst Lanko®Deep Dyneema DM20 fiber rope for 3400m operational depth."The crane is the first of its type and provides the ability to lift heavy loads at depths that normally require much larger cranes on larger vessels…

Med Marine Delivers New Tug to Kenya Port Authority

Kenya Port Authority's new tug, Mwokozi II, was delivered to her home port of Mombasa on January 10, 2022.The Mwokozi II is a custom design 42-meter, 120 tonne bollard pull RAstar 4200 salvage and harbor tug developed by Robert Allan Ltd., with particularly outstanding performance in maneuvering, seakeeping, and stability.The Turkish shipbuilder Med Marine was contracted to build the new tugboat at its group owned Eregli Shipyard. The keel was laid on March 23, 2020, and construction…

Port of Beaumont Starts Construction on Main Street Terminal I

The Port of Beaumont announced its Board of Commissioners have approved a $57.3 million construction bid for a project aimed at increasing the port’s general cargo handling capacity by more than 15%. Phase II of the Main Street Terminal 1 project, awarded to McCarthy Building Companies, includes demolition of a failed dock structure and construction of a new state-of-the-art general cargo dock. The Main Street Terminal 1 project, funded in part by 2017 General Obligation Bonds, a 2019 U.S. DOT BUILD grant, and Port revenues, is expected to be complete by June 2024.

First RAstar 2800-CL ASD Escort Tug Delivered

Svitzer Suez 1, the first RAstar 2800-CL ASD escort tug, has been delivered to Svitzer Egypt LLC by Cheoy Lee Shipyards and will soon commence operations in the Suez Canal. Svitzer are the first owners of this new escort tug design and a further nine tugs to this design have already been ordered with Cheoy Lee.The RAstar 2800-CL design started with a “blank sheet of paper”, according to naval architecture firm Robert Allan Ltd., who said one of the primary goals of the design was to make it extremely flexible allowing for various propulsion machinery options…

Tech Files: Offshore Safety Systems & Equipment

Safety of workers,structures, equipment and the environment are paramount in any offshore energy project. In the March/April print edition, Offshore Engineer took a look inside some notable newcomers.Wearable tech to boost drill floor safetyHaloGuard – Credit: TransoceanOffshore drilling contractor Transocean has recently deployed what it said was the offshore drilling industry’s first safety system that integrates a wearable locating device with drill floor equipment and machine stoppage controls.The system…

MacArtney LARS for Fifth Asia Pacific Research Vessel

MacArtney completed its order of a launch and recovery (LARS) system for Taiwan National University, the fifth Ocean Research Vessel (ORV) in the Asia Pacific region to date. MacArtney Asia Pacific provided the full launch and recovery system solution for the new vessel R/V New Ocean Researcher 1 (ORV 1), including slip rings, cables and docking heads. The 1,000 GT RV was completed on July 21, 2020.Behind ORV 1 is the CSBC Corporation, which built the ship for end-user Taiwan National University. CSBC, owning two shipyards, is the largest shipbuilding company in Taiwan.

Fast Water Imperils Tricky Night Move

In late Spring at about 0300 local time, an aging towboat (#1) was pushing two loaded barges upbound on a swollen and fast-moving northwestern U.S. river. It was a moonless night and, while certainly not unusual conditions for the veteran captain and his longtime deckhand, it didn’t diminish the added challenges of the short but tricky nocturnal run. And, as towboat pilots know, activities and hazards that are literally clear in daytime hours, take on a decidedly different complexion after the sun sets and inky darkness envelops the river and shrouds its banks.

Van Oord, Hendrik in Lifting Equipment Deal

Dutch maritime contracting company Van Oord is partnering with compatriot company Hendrik Veder Group for the management of heavy lifting equipment for offshore wind turbines.Rotterdam-based company active in steel wire and fibre rope products and services said that under the terms of the two-year agreement, Van Oord will outsource its hoisting and lifting equipment management to the Hendrik Veder Group, with a focus on sustainable lifting.According to Michiel Pieterman, Offshore Wind Operations Manager at Van Oord: "This partnership enables us to use lifting equipment in a sustainable way. The high-quality lifting equipment has a longer lifespan, because it is either reused or converted into new raw materials, while guaranteeing 100 percent compliance at all times.

MacGregor Builds 1st Offshore Fiber Rope Crane

MacGregor, part of Cargotec, has completed the construction of FibreTrac, the first fibre-rope offshore crane to enter the market.The FibreTrac crane has a 150-tonne safe working load (SWL) capacity. It features a rope monitoring and management system that maximises rope lifespan and provides clear lift line status information for the operator at all times. It is designed to comply with DNV GL regulations."The project to build, certify and validate the MacGregor FibreTrac crane is the result of our confidence in its potential," says Høye Høyesen, Vice President, Advanced Offshore Solutions, MacGregor.FibreTrac uses existing, proven technologies…

BOATBUILDING: What’s in Your Workboat?

Moose Boats rises to the challenge of building its biggest vessel ever. That’s an important step forward for this growing California shipyard. Equally impressive is what’s inside that rapidly developing hull and why those features were chosen.The U.S. boatbuilding scene is a changing landscape of waterfront manufacturing that constantly evolves to meet the inevitable peaks and valleys of demand. Nowhere is that reality more apparent than at California-based Moose Boats. In October 2016, Lind Marine announced the acquisition of Moose Boats. That move was important because Lind Marine operated a 5-acre shipyard including a 430 foot dry-dock and 1,600 feet of linear pier on Mare Island in Vallejo, CA.

Lankhorst Appoints Commercial Director

Maritime and heavy lift ropes company, Lankhorst Ropes, has appointed Mark Pieter Frölich as commercial director for Lankhorst Ropes USA. Based in Philadelphia, Frölich will head the development of Lankhorst Ropes’ sales in the maritime and offshore markets in the United States and Canada.Lankhorst Ropes is part of Kansas based WireCo WorldGroup, a steel wire and synthetic ropes maker. Previously regional manager for Lankhorst Ropes in the Middle East, Frölich has spent the past seven years successfully founding and growing the WireCo WorldGroup branch office in Dubai.

U.S. Coast Guard Looks beyond Mooring Lines

Strength, Safety and Sustainability are at the heart of this Homeland Security stakeholder’s mission set.For over 30 years, high performance fiber rope manufacturer Phillystran has worked with the U.S. Coast Guard to supply mooring and towing lines. As innovations in fiber rope technology have enabled lighter and stronger ropes, the Coast Guard has not been slow to take advantage of these and other developments.In step with most maritime stakeholders, NAVSEA approved fiber ropes are widely used by the U.S. Coast Guard.

Tug Pair Delivered to PSA Marine

In August 2018, PSA Marine Singapore took delivery of two new 32-meter tugs, PSA Thor and PSA Hulk, built at PaxOcean Engineering Zhuhai Co., Ltd.The evolved RAmparts 3200 ASD hull form has been developed by Robert Allan Ltd. to provide ship assist in the berthing and un-berthing operations in ports/terminals and also coastal towing operations. Tugs of this design are capable of escort service as well. PSA Thor and PSA Hulk feature a uniquely styled deckhouse and wheelhouse developed exclusively for PSA Marine.The two new tugs join to PSA Marine’s existing fleet…

Samson Launches Solution to Streamline MEG4 Transition

Samson, the developer of high-performance synthetic rope solutions and global market leader in commercial marine applications, has launched a new integrated technology and service solution, Icaria, designed to facilitate the transition process to MEG4 operational best practices.OCIMF’s release of the fourth edition of its Mooring Equipment Guidelines marks a significant change in how mooring systems will be designed, selected, maintained and retired. In addition, terminology has been clarified…

Ports of Indiana: Building on Success

The Ports of Indiana is a statewide port authority, established in 1963, which operates three ports: two on the Ohio River, one on Lake Michigan. Port officials refer to the three as “America’s Premier Inland Port System.” They cite location, location, location, providing access via two critical freight arteries – the Great Lakes and the Inland Waterway System and proximity to the world’s most productive industrial and agricultural regions. The Ports is the only statewide port authority in the Midwest.

The Best Options for Safe Mooring

The use of High Modulus Synthetic Fiber (HMSF) mooring lines, including Ultra High Molecular Weight Polyethylene (UHMWP) lines continue to make one of the most dangerous evolutions aboard ships safer. A 2017 UK Marine Accident Investigation Branch (MAIB) safety report, however, highlights critical areas where additional engineering review and crew training is required to help ensure overall crew safety. MAIB Report no: 13/2017 dated June 2017, addresses the finding from the March 2…

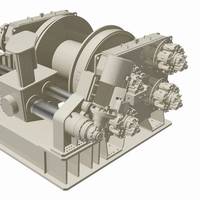

Markey ARR Winch System: Tried & Tested in the Toughest Tug Challenges

For more than 30 years, Markey Machinery has worked with the LNG and marine transportation Industries with the goal of developing winches designed to work under the most challenging conditions. The effort includes extensive design shop testing and actual commercial work, a combination that has ultimately produced an understanding of the operational issues facing terminal and tug operators. The many milestones in the development of Markey’s Asymmetrical Render/Recover (ARR) – technology by which hawser winches are able to maintain mean line pulls up to the bollard pull of the tug – came over a period of time that spans 25 years. The initial 20+ years of hawser winch design and Render/Recover development followed a traditional design path, influenced, in part, by market pressures.

Shaver Transportation Selects Rapp Marine Winch Package

Shaver Transportation of Portland, OR, operating vessels within the Columbia River region of the Pacific Northwest for over a hundred years, has selected Rapp Marine as the supplier of the two heavy-duty load handling winches on their latest tugboat. Rapp Marine has almost two decades of experience of designing and delivering rugged winches for workboat market, and has been around as a company for over a hundred years as well. The latest tugboat to the Shaver Transportation fleet is designed by Jensen Maritime of Seattle, WA and is under construction at Diversified Marine of Portland, OR.

Baydelta Chooses Rapp Marine Electric Tow Winch

For several decades, Rapp Marine has designed and delivered towing winches for workboat market. Combining the best ideas from Rapp’s past work in the other commercial industries and recommendations from the tugboat operators, Rapp Marine has developed long lasting and dependable towing winches. These past towing winches have mainly been powered using hydraulic systems in the North American market. Rapp Marine has previously delivered electric winches to commercial vessels in other industries such as research, oil & gas, and fisheries for years.

Tug Newbuild Alcor Delivered to Navibulgar

On June 2, 2017, MTG-Dolphin Shipyard delivered to Navigation Maritime Bulgare (Navibulgar) JSC the tug Alcor, the first of three vessels in series built to the RAmparts 2700 design by Robert Allan Ltd. The tug adds to the fleet of four tugboats in the Navibulgar fleet and is the first tugboat built by the Bulgarian shipyard MTG Dolphin PLC-Varna for the Bulgarian ship owner, who owns more than 30 bulk carriers. The naming ceremony took place on June 2 at Port of Varna and was attended by the Deputy Governor of Varna. The vessel is named after the star Alcor from the Big Dipper constellation.

Dual-fuel Escort Tug for Østensjø Rederi

The first of three new dual fuel RAstar 4000-DF class extreme escort tugs, the Dux, has been delivered to Østensjø Rederi AS by Spanish shipbuilder Astilleros Gondán S.A. Designed by Robert Allan Ltd., the 40.2 meter vessel is the first of a three boat order from Østensjø for severe weather operations at Statoil's Melkøya LNG Gas terminal at Hammerfest in the extreme north of Norway. These escort tugs will conduct approximately 300 LNG ship escorts annually, assist with berthing operations and will be maintained in readiness for emergency services such as long line towing…