MetalCraft Marine

Small Company with Big Ambitions Celebrates 25 Years

On the occasion of Metal Craft Marine’s 25th anniversary, Maritime Reporter & Engineering News ventured north, to the boat builder’s Kingston, Ontario headquarters, to discover the secret to its success.

Metal Craft Marine is well regarded in maritime circles for designing and building high performance craft outfitted for the most demanding work conditions. While the company is diverse in its work scope and capability, its history lies in high-performance jet boats and its current core competency lies in the construction of tough fire boats and military boats for worldwide use.

Like many small boat builders in its genre MetalCraft has a colorful story to tell. It literally starts with the company’s location, in Kingston, Ontario, Canada, on the northeast bank of Lake Ontario, where there has been a boatbuilding operation dating to 1676.

MetalCraft Marine Inc. is slightly younger than that, born in 1987 when Monty Smith, the founder, bought out Kingston Aluminum Yachts. In the beginning it was Monty and Tom Wroe, the general manager and President, who had worked together at Kingston Aluminum Yachts. “They were building these magnificent sailing yachts, beautiful boats,” said Bob Clark, contracts manager, MetalCraft Marine. But that business was short lived. According to Clark it was the proceeds from a lucrative real estate deal that enabled Smith to purchase the company from Kingston Aluminum Yachts, and soon thereafter they changed the name to Metal Craft, as well as the direction toward the patrol and workboat market. “Boat number one was Tom’s first power boat design,” said Clark. “And believe it or not, it is the hull shape of the 70 (the company’s new 70-ft., 40+ knot fireboat) that we were just on. It has been an amazingly successful hull shape for the company.”

While MetalCraft certainly enjoys a successful business today – including the fact that it is the only Canadian commercial aluminum boat company to have a U.S. GSA contract (GSA contract No. GS07F0084J ) – steady business and financial success were not always a given, as Clark explained. “The company was so poor then (at the beginning, with the delivery of its first government boat contract) that the inspector upon trialing the first boat said ‘I told Tom I am never going to do sea trials on a boat again that doesn’t have a windshield!’ And it was December.”

Clark joined the company as a consultant in 1991 when it had only four employees. “The primary problem for small companies is that when the same guy designs the boat, and the same guy builds the boats, it’s hard to find time to actually sell the boat.”

“So I went with Tom to see Lachine Rapids Boat Tours in Montreal, which is a very successful boat tour operator owned by two brothers from Pittsburgh,” Clark said. “We were trying to sell them the first boat for Niagara, and during the discussion I am literally kicking Tom under the table because he’s about to give something away – and this is still something we do to this day. From that meeting we walked away with a $20,000 check and a commitment for a $130,000 boat, and we ended up building five or six of them, and we’re great friends with these guys to this day.”

Humble beginnings helped to lay the foundation, and MetalCraft's adherence to high technical standard and sound financial principle have helped it grow to 130 employees at three locations, with a penchant for success in designing and building high speed Patrol and Search & Rescue craft. In 2013 it will deliver its 600th boat, and for 2.5 decades it has been a leader in jet boat design introducing its first power boat ever, the Kingston, as a jet drive boat in 1987. In fact the company's Kingston jet design was selected by the U.S. Navy for the Force Protection Program and served in the War on Iraq.

From Canada to the U.S.

In 2007, MetalCraft Marine U.S. Inc. began operations in Clayton, NY, a move facilitated by its desire to pursue and win Jones Act and U.S. Government work. “We had to get a site in the United States because the boats (for the Coast Guard) have to be built in the U.S.,” Clark said. Though it was established in New York to attract government work, the first contract signed for the New York facility was for the Whirlpool Jet Boat Tours operating in Niagara. The company has built many boats in New York, with the latest being eight specialty towboats for the U.S. Navy and a 36-ft. pilot boat for the State Pilots Association.

In addition, MetalCraft Marine U.S. Inc. is building boats for the U.S. Coast Guard, and have recently commenced building a pilot boat for Key West, Fla. While the move to New York was strategic, it soon became evident that the facility in Clayton was too small, with a 3,500 sq. ft. shop and literally no room to grow. “it was right on the water, an old factory with multiple levels,” Clark said. “It’s hard to build boats on multiple levels.”

The answer is a short drive up the road, 11 miles to Cape Vincent, that had two beautiful buildings that simply needed updates and a few custom upgrades. In addition, there is a 10,000 sq. ft. building on the Cape Vincent site, which the company has started renovation for future work. The expansion to Cape Vincent means an expansion in hiring, as well, with the addition of skilled craftsman such as aluminum welders, marine mechanical and electrical systems technicians and metal fitters and finishers. Even with the new facility MetalCraft is seemingly busting at the seams, but the company is cautious of too much too soon, eyeing the cyclical nature of the boatbuilding business and the carcasses of boat builders who have bitten off more than they could chew.

When asked his thoughts on what might trigger further expansion, Clark said, “It would probably be one of the multi-year contracts that we have out on bid. We have two Navy contracts out there that are not awarded yet; there’s a Middle Eastern contract; if we win one of the multi-year contracts, that would likely trigger the construction of additional buildings in New York.”

Government Rules

While prospects are generally bright, there are a few storm clouds being eyed by MetalCraft and the entire marine industry, namely the result of the U.S. election and the direction of government spending in the U.S. “We are very concerned right now that you can’t see any reality on (U.S.) government spending for 2014-15,” said Clark. “The Canadian government spending on marine is miniscule, and the government rules to work with are much harder than the U.S. rules. Canadian rules are very confusing. I’ve asked plenty of U.S. competitors to come and bid here, but when they read a spec, they simply say ‘garbage.’”

While the Canadian rules are onerous according to Clark, with its insistence on low-price evaluation “that has effectively killed the ability to build boats profitably for the Canadian government,” he said that the situation looks to be changing with the current conservative administration.

“They had a report written by Price Waterhouse last year called the Jenkins Report, it was a report on R&D spending for the government, and it essentially said that the government wasn’t getting its full bang for the buck,” Clark said. “In this report they specifically cited that our government purchasing is not supporting new technology, because it is so insistent on low price.”

Business in Hand

To date MetalCraft Marine has delivered 564 boats, and with 18 under construction (about 60% of them fireboats, as well as several crewboats for Panama), it is on course to deliver its 600th boat next year. While quality boats with minimal warranty items are crucial, Clark believes that customer service – specifically treating customers better than anyone else – is ultimately the pivotal point in gaining, building and retaining a loyal customer base over the long run.

“I remember in the early years that we received 12 inquiries, and I closed on seven of them. And I remember thinking ‘Wow, we received a lead a month,’” Clark said. “Today, the phone literally doesn’t stop ringing. Last year at the Workboat Show I walked away with eight solid leads, and your first inclination when you return is to get your package out to everyone. The week after the show, we received an additional $35m in business leads that were in no way related to the show; they hadn’t even been to the boat show; they didn’t even know about the boat show. It was unbelievable.”

“(Right now our business is) about 60% fire; we have the crew boat project for Panama; we have a pilot boat project and the LRI project on in New York; and we have a couple of small patrol boats building for Nigeria, and we are just closing a nice deal in Kuwait for fire and workboats,” Clark said.

The latest addition to the MetalCraft line-up is the 70-ft. fireboats; large, fast boats with high pumping capacity. Currently there are five in operation with three under construction.

“The 70 footers, each one of them has been a world record holder,” Clark said. “As a planing boat, there are very few fireboats that size that are planing boats, but it’s their pumping numbers – 17,000 gpm – that are the highest in existence for a boat that can go that speed. The Jacksonville boat was the fastest (70 footer) at 41 knots, and we are expecting the Houston boat to be 43 to 44 knots courtesty of more horsepower, as well as bigger pumps capable of an estimated 18,000 gpm.

Clark explains that the three boat, $15m deal for the Houston boats is a particularly interesting project, and currently there are ongoing discussions to add a fourth back-up boat to the fleet, given the vast expanse of operation and the critical petrochemical industry in the Houston Ship Channel to protect.

“There are so many places in the world that can use fast, high pumping capacity boats,” said Clark. “Typically they use old tug type displacement vessels travelling at 12 knots. The boats Houston are replacing are old, and the cost of maintenance was approaching $100,000 per boat, per year to keep them running 90% of the time.”

The final fit and outfit of any vessel is of course depending the particular client’s need, but Clark highlight the speed and the pumping capacity as central to their success. In addition, the Houston vessels feature a data link camera system that is designed to work with local police, police helicopters and other first-responder agencies, in order to deliver a homogenous and consistent picture of the situation to all parties, and to allow the crew to gather data and initiate preparation enroute.

The 70 foot fireboats are a step up from MetalCraft’s 50-foot fireboats, which are 35 knot boats wih pumping capacities in the 7,000 to 8,000 gpm range. “Simply put, there physically was no more space to put pumps on the 50 foot boat,” Clark said.

Future Challenges

While MetalCraft has enjoyed a good run, it is not immune from standard challenges to running an efficient company, and according to Clark the company’s challenges are hardly unique in this sector: The finding and retention of qualified technical talent. While the challenges may not be unique, some of the solutions employed certainly are, including:

A 4-Day Work Week

•“We went to a 4-day week this year. The concept behind it is greater retention of employees; as it really helps out young families that don’t make a fortune to save money on child care, for example.”

Health Care

•“We still don’t have a health plan in NY. Our company (in Canada) pays 0.98% of payroll to cover the basic health costs for our employees. On top of that we have a benefits package that covers their drug plan, their dental and vision ... and it costs a family $50 for coverage.”

Training

•“A Training program that we did with St. Lawrence College was a unique as it was an R&D program as well as a training program on new technology welding machines. We didn’t feel that we were maximizing the high technology capabilities of these machines, so we conducted a study and re-wrote all of our welding procedures, which are in accordance with ABS standards” and trained its workers to the new standards

Apprenticeship Program

•Another big thing that we just started was the New Zealand Boat Builders Apprenticeship program. We started just this month, but to get it rolling it took 1.5 year in planning.

We hired a course instructor that works part time; he’s a wooden boat builder and lives on Wolfe Island (Wolfe island is the home to MetalCraft Marine’s R&D center, situated and connected by ferry two miles from the Kingston, Ontario facility, and a half-mile from the Cape Vincent, NY facility). We set up a classroom on Wolf Island making it equally accessible for U.S. and Canadian guys. Today we have 17 enrolled, with a maximum capacity of 20 to 25 for now.”

MCM, BCGP Win USCG High Speed Patrol Boat Contract

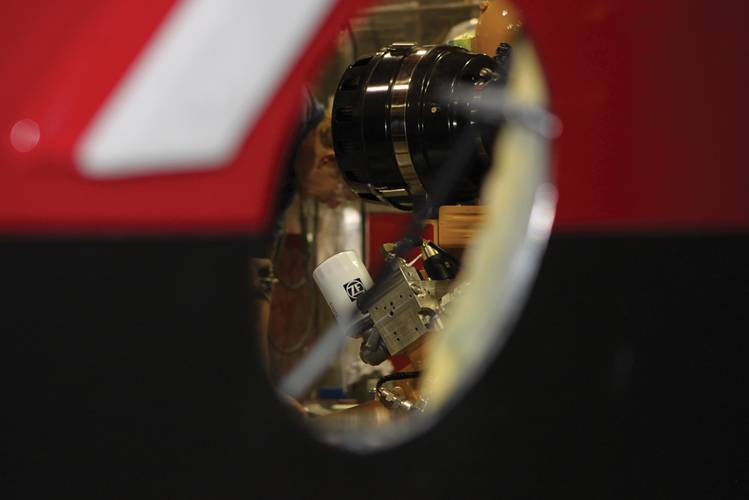

MetalCraft Marine US Inc. (MCM) and partner Brunswick Commercial and Government Products (BCGP) won a contract for the design and production of the new generation LRI II for the USCG, a five year contract is valued at $10.1m. LRI II is powered by twin Cummins Tier III 6.7L 480 hp diesel engines and Ultra 305 water jets, through ZF 280 PL Transmissions with electronic joystick controls. The engines are JP-5 or alternative Bio-Fuel optional and have a five-minute run dry feature.

All systems are designed for equatorial and arctic conditions, and each patrol boat has a fully integrated standard Coast Guard Furuno electronics package. The high speed LRI II patrol boat has a range of 236 nautical miles on plane and can reach 42 knots. The boats have the ability to operate up to Sea State 5 and can carry 15 crew or passengers in ergonomic suspension seating from Shoxs and Bostrom. The hull structure is designed to ABS High Speed Naval Craft standards, and all systems are designed to ABYC and CFR 46 standards.

ZF & MCM: A Strong Parntership

ZF Marine is a leader in marine propulsion systems, and it has enjoyed a long and mutually beneficial relationship with Kingston, Ontario based MetalCraft Marine in providing transmissions for the boats they build. In fact ZF has built its marine business on a strong presence in the high speed, high performance boat market, and this extends to a long cooperation with the U.S. Coast Guard, and most recently its FRC project.

“ZF has a long history of supplying mairne propulsion systems to the Coast Guard,” said David Santos, ZF Marine. “The 12 vessels under construction at Bollinger are very important to us. Being part of the U.S. defense is an honor for us.” Earlier this year, the USCG vessel Bernard C. Webber, the first of the new 154-ft. Sentinel Class Fast Response Cutters (FRC), was commissioned at Coast Guard Sector Miami. ZF Marine provided two ZF 23560C Marine Transmissions for each vessel. The ZF 23560C is only the latest in a long line of ZF Marine transmissions that have served the US Coast Guard over the last 27 years. The first were installed in the 110-ft. Island Class patrol vessels back in 1985. Since then, ZF Marine has supplied transmissions to the US Coast Guard for nearly 10 more vessel applications. Today more than 200 US Coast Guard boats and cutters are sailing with ZF Marine transmissions.

“Future growth for govt. business is a major part of ZF’s strategy in the marine industry. We believe there is a good opportunity,” said Santos.

(As published in the November 2012 edition of Maritime Reporter - www.marinelink.com)