Olmsted: Online & Open

After more than 30 years of frustratingly slow progress, cost overruns and more than a few mistakes, Olmsted is finally poised for success. That’s something to celebrate.

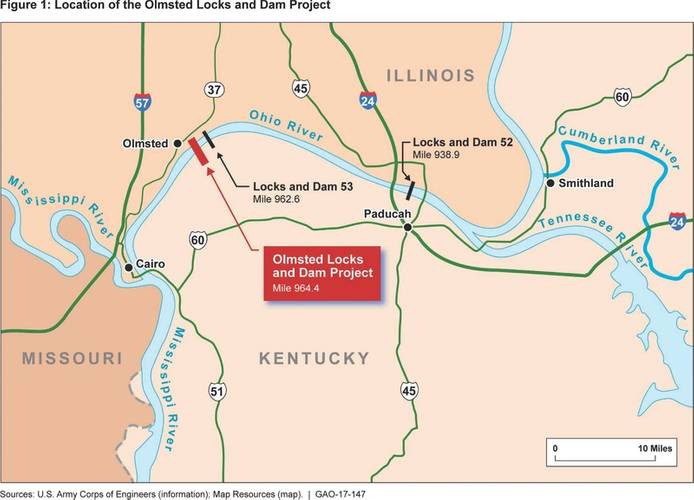

It is official: The U.S. Army Corp of Engineers (USACE) wants Olmsted operational by October. After more than 30 years, the ribbon cutting to officially open the Olmsted Locks and Dam took place on August 30. The very old (1929) upstream locks and dams – Nos. 52 and 53, which Olmsted is replacing – will be dismantled by December 2020. Before that happens, Olmsted’s performance will be tested and confirmed. On the Ohio River at Olmsted, IL, about 10 miles north of Cairo, IL, where the mighty Ohio flows into the mighty Mississippi, this crucial piece of American infrastructure is finally almost in place.

- The Agony of Olmsted

To say that the 2,596-foot Olmsted dam is situated on a vital section of the Nation’s inland waterways would not give full weight to the importance of this critical infrastructure. The tonnage passing through this section, over 90 million tons annually, exceeds every other section of America’s inland navigation system. Olmsted isn’t just about critical transportation – its operations are integral to the entire Midwest economy.

Olmsted was first authorized within the Water Resources Development Act (WRDA) of 1988 at a cost of $775 million, with construction estimated to take seven years. An appropriation for construction was first made in 1990 but the Corps did not award money for a construction project until 2004 – 14 years later. The 1990s were given over to technical analytical work regarding a construction method – evaluating the more traditional “in-the-dry” method, using cofferdams which block the flow of water around a site, versus a newer, but less familiar “in-the-wet” method, more difficult but promising more flexibility and a lower final cost. ‘In-the-wet’ was chosen in 1997, and a new construction estimate was arrived at: six years. But, even the in-the-wet decision didn’t deliver much certainty. It was repeatedly re-examined, even as late as 2012 – eight years after initial project funding.

Contracts were also a challenge. In 2002, the Corps requested proposals for construction as a firm fixed-price, but received no offers, because according to subsequent Corps’ analysis, the construction method was innovative, the river conditions were too risky, and a potential contractor could not get bonding.

In 2003, the Corps offered a cost-reimbursement contract, receiving two offers. In 2004 – sixteen years after authorization – a contract was awarded to Washington Group/Alberici (WGA) Joint Venture. The winning proposal was $564 million. Still another new construction estimate (8 years) was arrived at. Nevertheless, the project continued to flounder.

In 2006 and again in 2011, new baseline estimates projected cost increases – by $81.6 million in 2006 and by a whopping $551.1 million in 2011 and increased the construction schedule by 4 to 5 years. There were many reasons, some external to the project. Everyone had an excuse. The 2005 hurricane season, which included Katrina and Rita, created a scarcity of barges and cranes when the contractor was trying to mobilize equipment and barge prices doubled. From 2002 to 2007, fabricated steel prices increased about 300 percent, cement 90 percent, and fuel about 300 percent. Insurance and bonding costs soared by 230 percent.

Fundamentally, it was the numerous struggles with in-the-wet construction that checked early project momentum. The dam portion of the project, for example, included pre-cast concrete shells, building blocks weighing up to 5000 tons each, moved from a fabrication site, via a rail sled, to a catamaran crane barge – the largest in the world – and then moved upriver, and lined up at a 30-foot depth across the river bottom, an underwater task demanding ¼ inch tolerances.

In many ways, the Olmsted project was remarkable; arguably the civil engineering equivalent to the Manhattan project. Nothing was off the shelf, just about everything had to be invented and developed.

In every aspect, Olmsted demanded an extensive and expensive learning curve.

- Angst on the Hill

Naturally, Olmsted’s challenges attracted Congress’ attention. In 2012, it was clear that Olmsted would exceed its maximum authorized cost. The Corps prepared a PACR – a “post authorization change report,” seeking to increase the authorized cost to $2.918 billion, approved by Congress in 2014. There were many related funding issues. Olmsted was gobbling up all of the money in the Waterways Trust Fund; leaving very little for other critical projects. Congress’ 2014 legislation limited how much Trust Fund money could go to Olmsted, from a 50% Fund share to 25% and then to 15%.

Critically, Congress also declared that Olmsted should get no less than $150 million/year until it was finished. These funding and policy shifts paid off. Work on Olmsted had been plagued by unpredictable and intermittent funding – sometimes work was deliberately slowed or delayed because of money issues. Once predictability was set, the project’s schedule smoothed out. Since the 2012 PACR, Olmsted stayed within the time and budget constraints of this critical reset. The PACR ceiling was $3,099,000,000. The 2016 total estimated cost: $3,059,266,000.

- Around the Next Bend in the River

The Corps estimates that Olmsted will produce average annual national economic benefits of more than $640 million. Operation and maintenance costs will be reduced. New locks mean fewer delays. Olmsted’s two 1200 x 110-foot locks will eliminate transit double-locking. Most tows on the Ohio – a towboat and 15 barges – measure 1150 feet by 105. Now, these sets will not have to break up and re-fleet. Lockage time will drop to less than an hour, compared to five hours through Locks and Dams 52 and 53 (when they work and often, they do not at precisely the wrong moment).

In 2017, late year infrastructure failure(s) at Lock 52 was unquestionably one of the biggest domestic maritime stories of the year. At one point, average delays of 65+ hours were being experienced by a queue 58 vessels and 658 barges waiting their turn. Another unscheduled maintenance issue saw Lock and Dam 52 closed for almost nine days in September. If time is money, then Olmsted is solid currency.

Illinois-based Garry Niemeyer, President of the National Corn Growers Association, presents a concise cost-benefit summary: He pays $0.40/bushel to ship corn via barge. Via train? $0.80. And, even worse via (environmentally inferior) trucks: $4.00.

- Lessons Learned

There were many lessons learned from Olmsted. In fact, and as part of the Water Resources Reform and Development Act (WRRDA) of 2014, Congress required the Corps to develop a Lessons Learned report. An extensive document, it spans the gamut from Dam Design, Contracting & Acquisition and, of course, Dam Construction.

Future projects, says the USACE, need to evaluate the risk of “less than optimum or uncertain funding” and impacts on innovative construction methods. Olmsted’s current leadership stressed that US lawmakers must adopt predictable financing to pay for mega-projects like Olmsted. Stop-and-start funding does not work. That’s because unrealistic estimates resulted in inaccurate costs and overly optimistic schedules which ultimately provided poorly reflected project risk.

Moreover, the USACE recommends working with the Corps’ Walla Walla Cost Engineering Center of Expertise to develop, sooner not later, dependable costs and timelines. Changes to final design need input from contractors. Plans developed by government architects and engineers had little input from contractors and changes led to delays and cost increases. To that end, projects expected to take more than five years need an annual review to monitor:

- Staffing turnover and loss of ‘historical knowledge.’ Managers need to “build the bench behind them and sustain technical competency.”

- Changes in regulations/requirements (safety manuals, environmental requirements, technical regulations, security requirements, etc.)

- Outdated technology and possible requirements for updates. Olmsted is newly complete, but this ‘new’ project starts with some equipment and material that is already 15-20 years old.

The most important lesson learned? That comes down to lessons applied on future projects. And, as much scrutiny as Olmsted (justifiably) received, it is all but certain that the next project will be watched just as closely to ensure that ‘lessons learned translate into efficiencies earned.’

On an inland river system that promises countless uncertainties lurking around every bend, that’s one lesson stakeholders can take straight to the bank.

Tom Ewing is a freelance writer specializing in energy and environmental issues.

This article first appeared in the September print edition of MarineNews magazine.