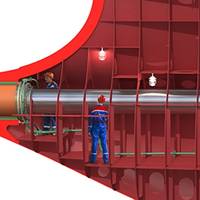

ABS AIP for "Sterntube-less" Ship

Thordon Bearings said ABS issued an Approval in Principle to the “sterntube-less ship” concept developed in cooperation with the Shanghai Merchant Ship Design & Research Institute (SDARI), the National Technical University of Athens (NTUA) and Thordon Bearings Inc.The design replaces a vessel’s sterntube with an irregular shaped chamber that allows a shorter, water-lubricated propeller shaft to be inspected and maintained while the vessel is afloat, without having to withdraw…

Canadian Coast Guard Opts for Thordon Bearings

CCGS Terry Fox, one the largest icebreakers in the Canadian Coast Guard (CCG) fleet, has returned to service with new Thordon propeller shaft bearings after concluding that fitting laminate phenolic bearings would extend drydock time and costs.The 88-meter-long vessel, built in the 1980s, had been operating Thordon’s water lubricated elastomeric polymer bearings on both shafts for 24 years. Then in 2018 the port shaft was retrofitted with a European made laminate phenolic-type bearing as part of a shaft alignment contract with the manufacturer.In December 2020…

DNV GL Updates Shaft Alignment Design Rules

Classification society DNV GL DNV GL informed that it will update its shaft alignment design rules to differentiate between Environmentally Acceptable Lubricants (EALs) and mineral oils in stern tubes.The update, will apply from 1 July 2019, and is based on the phase 1 findings from the joint development project (JDP) DNV GL has been operating along with the Swedish Club, Norwegian Hull Club, Gard and Skuld.The JDP was prompted by an upsurge in stern tube bearing failures that coincided with the increased uptake of EALs after the introduction of regulations requiring their use in commercial vessels trading in U.S. waters in late 2013.In phase 1 the JDP has focused on mapping out differences in the load carrying capacity between EALs and mineral oils.

DNV GL Revises Stern Tube Bearing Class Notations

DNV GL has revised its class rules for single stern tube bearing installations and introduced two new class notations, “Shaft align(1)” and “Shaft align(2)”, to help customers better manage the risk of stern tube bearing failure. The new class notations can be assigned to both newbuilds and vessels in service in conjunction with propeller shaft withdrawal. The classification rules covering shaft alignment are formulated to achieve an acceptable distribution of loading on the shaft bearings and lubrication of the aft bearing…

Voices: Rich Merhige, President/Owner, AME

AME is a Florida based engineering services company specializing in marine (Advanced Mechanical Enterprises) and industrial (Advanced Maintenance Engineering) predictive, preventative and corrective maintenance for rotating and reciprocating machinery. Founded by Rich Merhige in 1992, AME has pioneered the use of technologies and equipment to perform diagnostics, maintenance and repair, particularly for private and commercial vessels. As AME celebrates its 25th anniversary, discuss the decision to start the company.

ABS, Capital Ship Management Improve Propulsion Shaft Monitoring

ABS and Capital Ship Management Corp. (“Capital”), a distinguished ship management company, have collaborated to install an advanced condition monitoring system on the propulsion shafting of the Capital managed vessel M/T Agisilaos, a 36,700 dwt, Ice Class 1A IMO II/III Chemical/Product Tanker, built in 2006. The ABS Smart Bearing solution uses non-destructive testing sensors installed on the bearing pedestal and housing to measure and display the force exerted by the main propulsion shafting system onto the bearings, effectively converting the pedestal into a permanently installed weighing machine. “It was a pleasure working with Capital to develop the ABS Smart Bearing concept,” says ABS Chairman, President and CEO Christopher J. Wiernicki.

Keeping Machinery in Line with Laser Alignment

If you operate a vessel, its machinery, without a doubt, will require alignment many times during the course if its life. When misalignment is present components will be worn, efficiency will be lost, and, if left uncorrected, mechanical failures are imminent. This translates into a strain on mechanical systems, your budget, and your peace of mind. When speaking of alignment in marine applications, it is usually shaft alignment that is being referenced. Shaft alignment is defined as the positioning of two or more machines which so that at the point of power transfer from one shaft to another…

Dynaligner Aims to Eliminate Shaft Misalignment

A Swedish and Dutch invention aims to eliminate misalignment, modernizing today’s shaft alignment practice. The Dynaligner is said to offer trouble free operation of marine propulsion trains, irrespective of ship operation condition or hull deflections. Dynaligner ‘s developer said the propeller shafting is correctly aligned at all times during ship operation to avoid any mechanical behavior causing inappropriate bearing loads and wear/vibrations. The patented invention particularly focuses on, protecting the engine/gear, intermediate bearings and the stern tube bearings.

Ship Maintenance Goes High Tech

Machine reliability is a top priority and continuing challenge in marine applications, which operate in harsh conditions and at remote locations far from port and repair facilities. Ship operators can help keep machinery running efficiently by equipping their maintenance departments and crews with a full complement of new-generation maintenance tools. These tools, which range from high-accuracy alignment systems to precise automatic lubricators, can help avert premature failures and reduce the need for repairs at sea.

Dynaligner Aims to Eliminate Shaft Misalignment

More than 20 percent of all machinery claims, as well as catastrophic failure, off-hire and repair costs are caused by misalignment – the cause of almost all propulsion train damages Sweden’s Dynaligner AB said, adding that the problem is getting worse as modern ship design pushes the envelope. However, a Swedish and Dutch invention aims to eliminate misalignment, modernizing today’s shaft alignment practice. The device, the Dynaligner, is said to offer troublefree operation of marine propulsion trains, irrespective of ship operation condition or hull deflections, etc.

Alignment Supplies Debuts Shaft Alignment System for iPad

Greg Knitz, President of Alignment Supplies, Inc., announced the North American launch of the ALiSENSOR SHAFTLASER, a completely revolutionary new system for shaft alignment that combines all of the best aspects of Apple's iOS devices like the iPad and iPhone with the most streamlined and easy-to-use shaft alignment interface ever developed. “ALiSENSOR has already revolutionized the world of geometric measurement with the ALiSENSOR Level,” said Mr. Knitz, “and now they have changed the game for laser shaft alignment users all over the world.” At only $4…

Bureau Veritas Launches Elastic Shaft Alignment Notation

Classification society Bureau Veritas has introduced a new set of requirements for shaft alignment on high powered ships. The ESA notation will help ensure the integrity of the structure and shaft bearings on very large vessels such as ultra-large container ships and the next generation of very large LNG carriers. Jean-Francois Segretain, deputy technical director, Bureau Veritas, said, “As ships grow in size and we seek more fuel economies we are now seeing vessels with shafts handling over 20MW of power driving large diameter propellers of over 30 tons weight. Critical attention has to be paid at the design stage to analyzing the elastic shaft alignment and ensuring that the bearings and structure match the shaft response, especially when the vessel is turning.

Lloyd's Register Launches Machinery Damage and Repair Workshops

Lloyd’s Register is offering Machinery Damage and Repair workshops to support marine superintendents and engineering personnel. Mechanical breakdowns are a serious problem for ship owners, and having competent engineers on board can quite literally mean the difference between success and failure for a shipping company. The new workshops are unique to Lloyd’s Register and give even the most experienced engineers the opportunity to analyse and resolve some the most common mechanical problems found in the merchant marine environment. “The workshops are an innovative way to present real-life engineering problems with a variety of solutions in a controlled but time-pressured environment," said Steve Robson, Lloyd’s Register’s Senior Technical Training Specialist.

Norwegian Diesel Electric Joins Trend

Offshore shipping companies are increasingly turning to diesel electric propulsion systems as an efficient means of meeting the performance requirements for modern platform supply vessels. Builders in the U.S., China, Singapore and Norway have all delivered a variety of diesel electric vessels. In Norway the shipyard of Simek A/S recently they followed up earlier vessels when they delivered the M/S Stril Mariner to Simon Mkster Rederi AS in Stavanger, Norway. The Stril Mariner…

ABS Says Large Ship Hull Deflections Impact the Shaft Alignment

Larger ships, driven by the latest generation of very high-powered diesel engines, are particularly susceptible to alignment problems on the bearings supporting the propulsion shafting as well as the main engine bearings. Hull girder deflection is one of the major reasons for the increased number of propulsion shafting and the main engine bearing failures and damages that are being reported. Hull deflections are quite pronounced on large vessels where discrepancy between the flexibility of the hull and the shafting results in high sensitivity in the alignment dependent upon the vessel’s loading condition. Responding to industry need…

Propulsion Annual: ABS: Large Ship Hull Deflections Impact the Shaft Alignment

A report issued earlier this year from ABS indicates that larger ships, driven by the latest generation of very high-powered diesel engines, are particularly susceptible to alignment problems on the bearings supporting the propulsion shafting as well as the main engine bearings. Hull girder deflection is one of the major reasons for the increased number of propulsion shafting and the main engine bearing failures and damages that are being reported. Hull deflections are quite pronounced on large vessels where discrepancy between the flexibility of the hull and the shafting results in high sensitivity in the alignment dependent upon the vessel's loading condition.

LR Opens Shanghai Training Center

Lloyd’s Register Asia opened a comprehensive foreign-funded maritime training center in Shanghai. The new Lloyd’s Register Maritime Institute (Shanghai) was created to provide a center of learning from where working surveyors and auditors can share their technical knowledge with China’s shipbuilders, owners and maritime students through specifically tailored seminars, lectures and training courses. In 2009, the Lloyd’s Register Group will move the headquarters of its marine division from London to Southampton, creating a central Lloyd's Register Maritime Institute in conjunction with the University of Southampton. With the opening of the satellite training center, in Shanghai, LR said it is the first Asian extension of that strategy.

New Report: Alignment of Marine Propulsion Shafting Systems

The Society of Naval Architects and Marine Engineers released a 60-page technical bulletin Practices and Procedures for the Alignment of Marine Main Propulsion Shafting Systems. The bulletin was compiled by the Propulsion Shafting Panel, Panel M-16, of the Society's Technical and Research Program. While industrial machinery is typically aligned so that the shafts of the driving and driven machines are collinear, this approach is not appropriate for marine main propulsion shafting because the bearings move as conditions change, and because the shafting is never really straight as it deflects under its own weight and the weight of the propeller and other attached components.

Coast Guard Suspends Converted Patrol Boat Operations

The U.S. Coast Guard suspended normal operations of eight converted 123-foot patrol boats assigned to Coast Guard Sector Key West, Fla., due to additional structural damage recently discovered in the hulls. “I suspended the operation of all eight 123-foot cutters to ensure the continued safety of our crews as we assess additional structural damage recently discovered aboard this class of cutter,” said Adm. Thad Allen, commandant of the Coast Guard. “The reliable, safe operation of our cutters and aircraft is paramount to our effective mission execution, including vital search and rescue and migrant interdiction missions in the area.

GL Participates in INMARCO Conference

"Advanced Techniques in Tanker Design and Operation" is the topic of a presentation by Germanischer Lloyd experts at the INMARCO conference in Mumbai, India this week. The paper showcases safety relevant aspects in tanker building and the tools utilized by Germanischer Lloyd in the design of tankers. Such areas are sloshing, vibration, shaft alignment and crashworthiness. For example, GL uses the highly effective direct computation instead of model tests to predict the effects of sloshing. The one hour workshop "GL Academy - Discover the Maritime Knowledge World" takes place on November 24 and November 25 and presents an overview of the comprehensive maritime training programme by GL Academy. The seminars offer expert skills combined with wide-ranging practical experience.

Bulbous Bow Fabricated and Installed on M/V Monte Carlo

In March 2006 Bay Ship & Yacht Co. installed two new series 60 Detroit Diesel engines, a new bulbous bow, bow thruster, and a new reinforced rub rail on the dinner boat Monte Carlo owned by Hornblower Yachts. The initial design for modification work was drawn up by Dejong & Lebet of Jacksonville, Florida. Bay Design and Engineering provided detail design for most of the modification items, including a new engine bed design for proper shaft alignment, and CNC flat patterns for the bulbous bow. Layout, fabrication and assembly of the bulbous bow was accomplished on the drydock by Bay Ship’s experienced pattern makers and welding crew. Meanwhile, a new bow thruster was fitted and welded in place, and new gensets, shafting, boarding gates, sewage transport system and mast were installed.