U.S. Provides $9.98 Million to Strengthen Shipyard Competitiveness

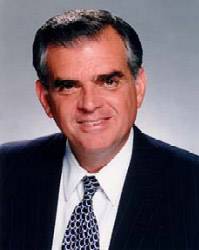

U.S. Transportation Secretary Ray LaHood announced $9.98 million in grants to 15 small shipyards throughout the United States to pay for modernizations which will increase productivity and help the country’s small shipyards compete in the global marketplace.

“In cities and towns across America, shipyards are creating jobs and keeping our nation's economy growing," said Secretary LaHood. "These small shipyard grants reflect the Obama administration's commitment to strengthening our transportation systems and creating an economy that's built to last."

The U.S. Maritime Administration’s (MARAD) Small Shipyard Grants Program provides equipment and technical skills training for America’s maritime workforce, helping these businesses compete in the global marketplace while creating well-paying jobs at home.

“They will provide new tools and equipment to help maritime businesses sustain and create good American jobs through increased productivity and efficiency,” said U.S. Maritime Administrator David Matsuda. “These federal investments will fund shipyard essentials.”

MARAD received 141 grant applications requesting $123 million in assistance. The grants fund a variety of projects, including infrastructure improvements and modernizing equipment to increase the efficiency, competitive operations, and quality construction of vessels in U.S. shipyards.

A detailed list of grantees is as follows:

• Allen Marine, Inc. (Sitka, Alaska) - will use a $163,500 grant to purchase a Welding Fume and Particulate Extraction System needed to meet Occupational Safety and Health Administration requirements for air changes per minute and to maintain the proper environment for aluminum welding operations.

• Bludworth Marine, LLC (Houston, Texas) - will use a $610,266 grant to purchase a rubber tire gantry crane to lift and transport barges, large modules, and materials throughout the yard.

• Bollinger Shipyards, Lockport (Lockport, Louisiana) - will use a $188,887 grant to purchase a robotic plasma pipe-cutting machine for fast and accurate pipe cutting, a big top tent structure to protect a vessel structure from the environment and to protect the environment from contaminants, and an induction heating distortion control system to reduce plate deflection and distortion.

• Chesapeake Shipbuilding Corporation (Salisbury, Maryland) - will use a $423,752 grant to purchase air compressors, personnel lifts, and a mobile grit recovery system to remove blasting grit from buildings and outfitting areas. In addition, the company will implement a cross training program to improve skill sets and utilize existing workforce more efficiently.

• Conrad Shipyard, LLC (Amelia, Louisiana) - will use a $1,117,019 grant for drydock modernization and upgrade to expand their 280-foot 10,000-ton floating drydock by 2,500 tons in capacity and 70 feet in length.

• Detyens Shipyards, Inc. (Charleston, South Carolina) - will use a $1,176,776 grant to purchase two 20-ton tower cranes that will be set at both ends of an existing drydock to facilitate increased and safer service to the drydock.

• Foss Maritime Company, Foss Seattle Shipyard (Seattle, Washington) - will use a $578,402 grant to purchase two 45-foot manlifts, a 14,000 CFM dust collection system to allow the yard to blast and paint without contaminating the atmosphere, a 3-ton forklift, and shelters for additional work overflow.

• Duclos Corporation DBA Gladding-Hearn Shipbuilding (Somerset, Massachusetts) - will use a $389,195 grant to fund shipyard infrastructure upgrades.

• Gulf Marine Repair Corporation (Tampa, Florida) will use a $1,083,055 grant to modernize and upgrade their 14,000-ton drydock.

• Kvichak Marine Industries (Seattle, Washington) - will use a $987,307 grant to purchase a water-jet cutting table to cut and bevel ferrous and non-ferrous plates, a hydraulic swing beam shear for accurate cutting in place of skill saws and band saws, lighting enhancements, a jib crane column replacement, and welding equipment. In addition, the grant will fund a training program in boatbuilding skills.

• LEEVAC Shipyards, LLC (Jennings, Louisiana) - will use a $667,324 grant to purchase a pipe and tube bending system, which will bend pipes to the correct geometry required, eliminating the need to weld pipe sections by hand.

• Liquid Waste Technology, LLC (New Richmond, Wisconsin) - will use a $558,843 grant to purchase two forklifts, a 50-ton rubber tire gantry crane for transporting dredges and modules throughout the yard, and a training simulator room with two computers and software.

• Navatek Ship Construction (Honolulu, Hawaii) - will use a $248,805 grant to purchase wind turbines and towers that will provide clean renewable electrical service to the yard.

• The Great Lakes Towing Company DBA Great Lakes Shipyard (Cleveland, Ohio) - will use a $1,068,474 grant to purchase lighting, a burn table for automatic cutting, a scissor lift, welding equipment, scaffolding, a high pressure lifting skid to lift and move heavy components, boom lift, generator, and a self-propelled transporter to move vessels and modules throughout the yard.

• Trinity Industries, Inc. (Caruthersville, Missouri) - will use a $718,395 grant to purchase a one-side welding system that will fabricate stiffened panels using a butt-welding station, a stiffener fitting station and a stiffener welding station.