GTT Develops Balast Water-Free LNG Feeder & Bunker Vessel Concept

French firm GTT has developed a versatile LNG feeder & bunker vessel concept for worldwide operation without the use of ballast water.

Every day, many ships carry on board a considerable quantity of seawater as ballast over the oceans. Technically, this is needed in empty or partially loaded conditions, in order to maintain seaworthiness, reach sufficient draft for propeller immersion, and avoid excessive bow slamming.

Such ballasting requires investment for the onboard systems and leads to substantial operating costs. In addition, sediments may cumulate at the bottom of the ballast tanks, creating further costs and corrosion problems.

On the environmental side, in addition to the generated emissions, transporting ballast water may transfer harmful aquatic organisms and pathogens when the ballast water is discharged in the arrival port.

The IMO Ballast Water Management Convention is dealing with this major global problem. In most cases today, the compliant solution is the installation of a ballast water treatment system.

However, the cheapest rules-compliance remains not to use any ballast water at all: then, the operator is 100% compliant without any treatment or investment.

Solutions with a so-called V-shape hull are generally proposed. The basic idea is to obtain a somewhat higher draft in the design load case, and by that, also maintain a sufficient draft for safe navigation, even when empty.

This principle can be used as far as a draft limit is not attained. For big deadweight carriers (e.g. Suezmax) it will be impractical.

The GTT concepts take full advantage of the specific membrane geometry: the hull lines and the incorporated membrane tanks are designed to match perfectly well, and free surface effects by the LNG are reduced when the ship is partially loaded.

GTT Developments

Over the recent years, GTT has been working in this space with different designers and shipbuilders.

Credit: GTT

Credit: GTT

The above image shows a 7 500 m3 single-screw design made in cooperation with FKAB in Sweden. Such a design is well adapted for small-scale distribution in highly sensitive areas such as the Baltic Sea.

« B-Free » 28,000 m3 LNGc design Credit: GTTWithin a Joint Industry Project, a 28k single-screw vessel with two tanks was designed. GTT Partners were Dalian Shipbuilding Industry Corporation, Lloyd’s Register, and Exmar from Belgium. The studies comprised a full sloshing test campaign at GTT, seakeeping calculations made by LR, the vessel design work done by DSIC, and interface and operation aspects reviewed by Exmar.

Credit: GTTWithin a Joint Industry Project, a 28k single-screw vessel with two tanks was designed. GTT Partners were Dalian Shipbuilding Industry Corporation, Lloyd’s Register, and Exmar from Belgium. The studies comprised a full sloshing test campaign at GTT, seakeeping calculations made by LR, the vessel design work done by DSIC, and interface and operation aspects reviewed by Exmar.

Also, the first batch of seakeeping tests was performed in the SSSRI ship model basin in Shanghai.

The outcome and good results are very promising. An AiP was issued by Lloyd’s Register, confirming the feasibility.

The « Shear-Water » project: extensive testing proves the concept

18,700 m3 LNG Feeder & Bunker vessel "Shear-Water"

Credit: GTTBuilding on the experience gained on the previous ballast-water-free projects, as well as the recently built membrane-type LNG Bunker vessels, GTT has developed a new concept for a vessel, which may serve either as LNG bunker vessel or as a regional feeder.

Credit: GTTBuilding on the experience gained on the previous ballast-water-free projects, as well as the recently built membrane-type LNG Bunker vessels, GTT has developed a new concept for a vessel, which may serve either as LNG bunker vessel or as a regional feeder.

The design includes numerous advantages, such as reduced investment & operating costs, simplified operations, reduced corrosion, and a prolonged lifetime.

Two identical cargo tanks are provided for simplified operations, and a very effective Anti-Roll-Tank is provided in the vessel’s fore part.

Compared with the two previous designs, Shear-Water has a twin-screw azimuth propulsion system, increasing the maneuvering performance and providing a high power reserve in harsh conditions when empty.

Emissions are reduced through lower consumption, on average by a power reduction of over 10% versus a conventional vessel.

Specific issues such as pilot boarding, trim regulation and dry docking were identified, investigated and solutions validated by design. Especially in coastal trades with frequent calls to major rivers, the benefits are substantial.

Hydrodynamics and liquid movements

Key design aspects are the hydrodynamics and liquid in-tank movements (sloshing).

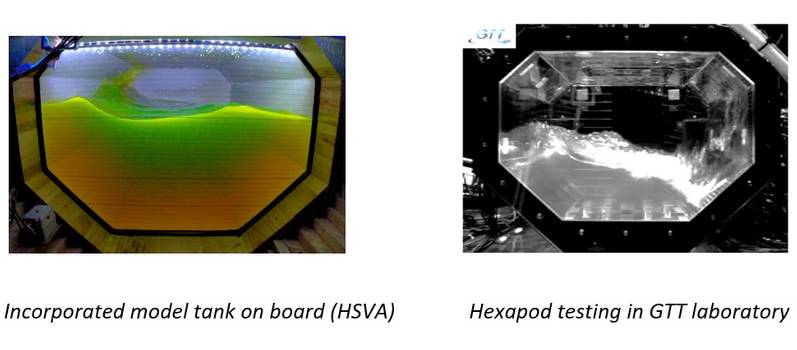

On behalf of GTT, an extensive test campaign was made by HSVA, The Hamburg Ship Model Basin. It validated the ship’s behavior in calm-water and the seakeeping in severe sea states. In GTT’s headquarters laboratory, the membrane system was validated for worldwide conditions without any filling restriction.

Credit: GTT

Credit: GTT  Credit: GTT Incorporated model tank on board (HSVA) Hexapod testing in GTT laboratory

Credit: GTT Incorporated model tank on board (HSVA) Hexapod testing in GTT laboratory

Both campaigns showed results ranging from good to excellent, GTT said.

Hydrodynamics

The tests were made with a self-propelled model in a scale of 1:18, a length of 7.75 m, and a laden weight of 2.8 tons.

Classical calm water tests covered speed-power and maneuvering. The outcome showed a power reduction of 10-15% for the range 10-14 knots when considering average values between fully loaded and empty conditions. All compared with the same size & same function, conventional vessel.

Maneuvering tests showed results exceeding IMO requirements and expectations.

The design shows perfect course keeping, combined with excellent maneuvering capabilities.

Seakeeping performance was tested in selected sea-states up to NATO Sea-State 7 (Hs 7.5m). No unusual, excessive or dangerous behavior in the selected sea states has been observed. Observations were similar to other ships in such conditions.

Tests and investigations covered motions and accelerations, rolling, including parametric excitation, slamming, Propeller immersion, green water, and speed loss in waves.

Course keeping in waves is considered good, and the ship was never found to be out of control.

Further tests were made for pilot transfer operations. Comparative tests with & without Anti-Roll-Tank (ART) showed a roll reduction of about 60%.

Additional separate tests were made with the incorporated (single) LNG tank, investigating coupling effects between tank liquid motions and external wave excitation.

Sloshing campaign and optimized Membrane containment system

A dedicated full sloshing campaign was made for worldwide conditions. The obtained good results show no filling restrictions for the chosen system Mark III Flex. The foam density is standard 130 and partially 150 kg/m3. The design Boil-Off-Rate with the above values is 0.165%vol./day. Credit: GTTGTT’s new Ballast-Water-Free design concept has been proven for safe navigation. Beyond this, « Shear-Water » marks a real environmental progress, combined with economic advantages.

Credit: GTTGTT’s new Ballast-Water-Free design concept has been proven for safe navigation. Beyond this, « Shear-Water » marks a real environmental progress, combined with economic advantages.

The concept may also be used in other ship types, typical candidates could be tankers, container ships and general cargo vessels.

Key operational questions are addressed and Approvals in Principle were obtained from three major Classification Societies. Full contractual maturity can now be reached in short time.

This is a guest post, and the views and opinions expressed in it are those of the author(s). They do not necessarily reflect the views of MarineLink.