Maintaining the Ship of Mercy

International faith-based organization Mercy Ships has used ships as traveling hospitals since 1978, providing health services to millions of people from the world’s poorest countries. Gathering praise from figures such as Nelson Mandella, Desmond Tutu, Jimmy Carter, George W. Bush and Tony Blair, the organization and its work have had a vast impact globally with more than 2.42 million direct beneficiaries to date and an estimated cumulative work bill near $1 billion.

Funded primarily through private donations, Mercy Ships is now operating its fourth vessel, Africa Mercy. Built in 1980, the vessel began her career as a Ro/Ro rail ferry for the Danish State Railway System and was acquired in 1999 through a donation from the Balcraig Foundation. By 2007, the ship was completely converted into a cutting-edge surgical hospital, giving Africa Mercy the title of largest nongovernmental hospital ship on the planet. The extensive overhaul provided capacity for up to 474 crew/staff, five operating rooms, five wards, labs, x-ray suite and other ancillary service spaces; but most importantly, the refit offered capability to help countless patients throughout Africa’s deprived coastal regions.

“Through the use of the hospital ship, Mercy Ships delivers world-class surgical interventions, most not available in the countries we serve,” said Don Stephens, Mercy Ships President and Founder. The unique mobility of the state-of-the-art specialist surgical hospital provides medical attention ranging from tumor removal and orthopedic repair to cleft palate reconstruction and dental care. Thanks to Africa Mercy, people who would not otherwise have access to such treatments can receive professional care in a controlled, clean and safe environment; roughly 7,000 surgical procedures are performed aboard the ship annually.

But as with all vessels of this scale, yearly maintenance helps keep the Africa Mercy fully operational for 10 months of the year. In June, the vessel made her third visit to Astican Shipyard in Las Palmas, Gran Canaria for scheduled repair and upkeep. There, Africa Mercy received “significant upgrades,” said Ken Berry, Mercy Ships Director of Marine Operations, including improvements to the ship’s engine and navigation and functional interior refurbishments.

Because the ship is 33 years old, many of its parts have become outdated and increasingly difficult to maintain. Astican replaced the ship’s original main engine lube oil purifiers with new purifiers supplied by Alfa Laval and added eighty meters of new piping to support installation. Similarly, the older X-Band radar is no longer supported by the manufacturer, Berry said, so a new Kelvin Hughs Ltd. manta digital radar unit was installed by the ship’s technical crew with crane support from the yard.

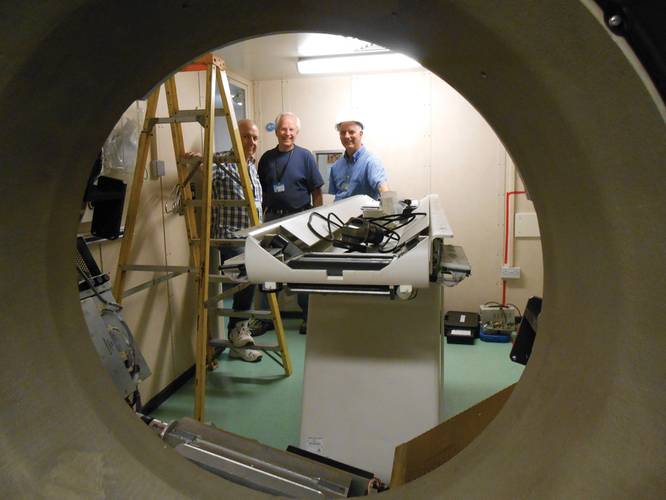

On the inside, much needed capacity was added to the hospital’s surgical operations as one operating room was transformed into a post anesthetic care unit, increasing ward space by 20%. Tennessee-based All Parts Medical supplied Africa Mercy with a newly refurbished GE VCT lightspeed 32-slice CT scanner for its x-ray suite. The yard also installed 600 sq. m. of Sika poured epoxy flooring to replace worn linoleum in the vessel’s wards and exam rooms.

Following its annual maintenance phase, the newly upgraded Africa Mercy will sail to Pointe Noire, Republic of Congo, Stephens said. There, the crew will begin a 10-month field service as it continues to bring hope and healing to the world’s poor.

The success of Africa Mercy has led Mercy Ships look toward expansion of its fleet with a newbuild. “Provisionally named the M/V Atlantic Mercy, this ship will more than double Mercy Ships’ capacity to serve underdeveloped countries as well as provide far more medical training capacity,” Berry said.

For more information or to donate, visit www.mercyships.org

(As published in the August 2013 edition of Maritime Reporter & Engineering News - www.marinelink.com)