Interview: Dirk Balthasar, President, Thermamax

To start, can you give an overview of the Thermamax offering to the maritime industry?Thermamax is a specialist in the design and manufacture of thermal and acoustic insulation solutions for diesel engines, spark ignited engines, exhaust aftertreatment systems and electric storage systems. Our markets include automotive, on- and off-highway sectors, power sports vehicles, stationary power generation, ships, and oil platforms, both on land and at sea. For the marine industry, Thermamax is a solution provider for SOLAS-compliant insulation solutions for engine rooms.

HEINZMANN leads in dual-fuel retrofit of marine propulsion engine

The use of LNG in marine applications is becoming increasingly common. It offers a big potential in terms of operating costs and emission reduction. Diesel engines converted to dual-fuel show considerably reduced emissions in case of high conversion ratios. Depending on the emission standard which is required, expensive and unwieldy exhaust aftertreatment systems can become unnecessary or their implementation costs are significantly lower. The engine performance is comparable to gas engines. HEINZMANN, a specialist in engine and turbine management solutions, offers dual-fuel retrofit systems for a wide range of diesel engines to be converted to gas operation and at the same time providing all the safety features required for marine applications.

Cummins Darlington: 50 Years of Engine Production

UK-based Cummins Darlington is celebrating its 50th anniversary during 2015. Since opening, around 1.5 million engines have been built in the factory for customers worldwide, providing power for vessels as well as land vehicles. Work began in 1963 on the £8.5 million plant with engine production commencing in 1965, having more than 400 employees’ onsite. The production line assembled Cummins range of Small Vee V6 and V8 engines, named VAL and VALE. With cubic capacities of 5.7 and 8.3 liters, they had a capability of up to 111 kW, suitable for a range of boats at the time.

Rolls-Royce Bolsters R&D for MTU Engines

Rolls-Royce Power Systems informs it is investing in the development of the next generation of ecological sound and cost efficient combustion engines at MTU, a brand in the Rolls-Royce Land & Sea division. With the first new test stands entering service today in Friedrichshafen, MTU’s lead site and main R&D location, Rolls-Royce said it has invested some 40 million euros in the new testing facilities at MTU. "This move is making space for new developments in every sense of the word.

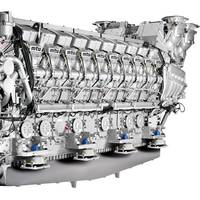

MTU Shows SMM it's Ready for IMO Tier lll

The Rolls-Royce brand MTU is showing its concepts at the current SMM, Hamburg, in response to the IMO Tier III emission standard which is due to come into force in 2016. “MTU is well-prepared for IMO Tier III, be it with SCR exhaust aftertreatment systems for diesel engines or with gas engines,” explains Dr. Michael Haidinger, Chief Sales Officer at Rolls-Royce Power Systems. In an animated presentation, MTU is demonstrating the latest high-speed Series 4000 gas engine based on its trusted 4000 M63 diesel engine which is widely used in working vessels. The first field-trial engine is scheduled to go into service in 2016 in a new environmentally-compatible tugboat. MTU's natural-gas marine engine is due to be launched on the market in 2018.

MTU Boosts Series 8000 Engine Power

Series 8000 marine diesel engines from Tognum subsidiary MTU Friedrichshafen GmbH now available with an output of 10MW. Previously, the 20-cylinder engine had a maximum output of 9,100kW. The IMO Tier II-compliant unit demonstrated its increased power and reliability during a project-specific endurance run over 1,500 hours under tropical conditions. The Series 8000 engines now cover a power range from 7,200kW to 10,000kW enabling MTU to offer economically efficient, diesel-based propulsion solutions producing up to 40MW per vessel.

Caterpillar's New Line of Gas-Fuel Generator Sets

Caterpillar Inc. Available in both 50 Hz- and 60 Hz-rated models, CG generator sets are designed for maximum efficiency in extended-duty distributed generation and cogeneration (combined heat-and-power) applications. Built for flexibility, CG generator sets can operate on gases of varying quality, including natural gas; biogases such as landfill, digester and sewage gas; coke gas; and coal mine methane. The new generator sets can be used in a variety applications, including industrial and commercial facilities, utilities, wastewater treatment plants, landfills, mines, greenhouses and farms. “At a time when energy efficiency and sustainability are on everyone’s minds…

Cummins Introduces QSK95 Marine Engine

Designed Ready to Meet EPA Low-Emissions in 2014. Most Powerful High-Speed Diesel Will Challenge Medium-Speed Engines. Cummins Inc., a manufacturer of diesel engines for the commercial marine industry, will introduce the new QSK95 engine with 4000 hp (2983 kW) output as the most powerful high-speed diesel configured for marine propulsion and auxiliary generator sets. The 95-liter, 16-cylinder engine, revealed today at the Seymour Engine Plant, is designed ready to meet EPA Tier 4 low-emissions regulations taking effect in 2014.