Wärtsilä Expands Predictive Maintenance Options

Wärtsilä said its digital predictive maintenance product is now being offered to support two-stroke engines and will be available for scrubbers at a later date.Originally launched in November 2019 for four-stroke engines, Expert Insight combines artificial intelligence (AI) techniques and rule-based advanced diagnostics with the knowledge and experience of Wärtsilä’s product experts to detect potential issues in asset operating data, and enable experts to provide actionable advice proactively.

Wärtsilä Launches Data-driven Maintenance Service

Wärtsilä introduces its Data-Driven Dynamic Maintenance Planning (Data-Driven DMP) solution aiming to increase the uptime of assets and reduce lifecycle costs by optimizing major overhaul intervals, without compromising operational reliability or engine efficiency.An enhancement to the company’s existing DMP solution, the new solution is part of the company’s Lifecycle Solutions offering and utilizes digitalization and Wärtsilä’s analytics capabilitiesAssets are maintained in prime condition without the need for on-site visual inspections performed by Wärtsilä personnel…

Taking CBM to the ‘Next Level’

As ship owners increasingly use data to schedule ship equipment maintenance, evolving from a calendar-based to a condition-based maintenance (CBM) regimen, Wärtsilä launches its Expert Insight predictive maintenance product, a digital product designed to enable customer support to be delivered proactively by Wärtsilä Expertise Centers to ensure long-term accurate insight for their predictive maintenance strategies. The product is available in combination with a Wärtsilä Lifecycle…

Wärtsilä Expands Propulsion Monitoring Services

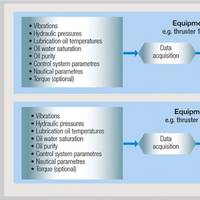

Wärtsilä expanded its offering in propulsion monitoring services. The Wärtsilä Propulsion Condition Monitoring Service (PCMS), introduced to the market in 2010, will now feature expanded functionalities and is now available in two editions - PCMS Starter and PCMS Professional. The need for certainty of operations and long-term maintenance planning is fulfilled with a new functionality - Dynamic Lifetime Prognosis (DLP). Wärtsilä Propulsion Condition Monitoring Service is a solution for monitoring propulsion equipment.

Wärtsilä’s Propulsion CMS recognized by 3 Classification Societies

Wärtsilä has received service level recognition for its Propulsion Condition Monitoring Service (PCMS) by DNV-GL. Wärtsilä is the first company to attain this type of recognition from three of the major classification societies, namely the American Bureau of Shipping, Lloyd’s Register, and DNV-GL. The approval, which was received in February 2014, means that surveyors from the classification societies may rely on Wärtsilä’s PCMS when assessing propulsion equipment. This eliminates the need for the compulsory five-year internal inspection, which often requires dry-docking. Instead, with the Wärtsilä PCMS continuously monitoring the equipment…

Wärtsilä Propulsion Condition Monitoring Service

Wärtsilä announced the launch of a unique Propulsion Condition Monitoring Service (PCMS), designed to provide customers with real-time data and advanced analytics on the condition of a vessel's propulsion equipment. Ship owners will have access to information and analysis needed to ensure that propulsion systems operate at peak efficiency throughout their lifecycle. PCMS allows ship operators to prevent damage and lower life cycle costs, as well as limit their vessel's environmental impact by keeping propulsion systems operating at high efficiency. The need for periodical inspection of propulsion equipment can be eliminated by successfully integrating PCMS in the maintenance program.