Wind-assisted Propulsion for World's Largest Ore Carrier

Brazilian mining firm Vale will install five Rotor Sails from Anemoi Marine Technologies Ltd (“Anemoi”), a supplier of wind-assisted propulsion technology for commercial vessels, onboard a 400,000 dwt Valemax, the world’s largest ore carrier. The vessel is owned by Omani shipowner, Asyad.Five 35-meter-tall, 5-meter-diameter cylindrical sails will be installed on the Sohar Max VLOC. The Rotor Sails will be installed on Anemoi’s folding deployment system, whereby the sails can be folded from vertical to mitigate impact on air draft and cargo handling operations.

MOL Opts to Equip Second Bulk Carrier with Hard Sail

Japanese shipping company Mitsui O.S.K. Lines, Ltd. (MOL) on Wednesday said it intends to equip a second bulk carrier with the Wind Challenger hard sail system, which harnesses the power of wind to propel the vessel, improving efficiency and reducing fuel consumption and emissions.MOL Group company MOL Drybulk Ltd. will operate the vessel, which will transport wood pellets for sustainable wood bioenergy producer Enviva Inc. and has signed a construction contract for the new ship with Oshima Shipbuilding Co.…

MOL Bulk Carrier to Trial Rotor Sails

Japanese shipping company Mitsui O.S.K. Lines, Ltd. (MOL) said it has entered into an agreement with mining company Vale International SA to install and trial rotor sail wind propulsion units on one of its a 200,000-ton class in-service bulk carriers in an effort to study levels of greenhouse gas (GHG) emissions reduction while underway.The rotor sail produces propulsive force as the wind generates differential pressure around the slewing rotor while the vessel is underway. It…

Design’s Future 3D Modeling, Virtual Reality Wave of Design Future

Rooted in early computer-aided design (CAD) and manufacturing applications, design and construction software is firmly at the helm of most shipyards today, enabling the production of better designed, more efficient and consistently built ships produced with measurably less waste: less waste of time, materials, man hours and most important, money. The ROI can be substantial, and is traceable throughout the entire process, across all sub sectors such as project management, purchasing, materials, labor and build sequencing.

Dmitry Kapiturov of Robert Allan acquires APEGBC Registration

Robert Allan Ltd. is pleased to announce that Mr. Dmitry Kapiturov has earned his accreditation as a Registered Professional Engineer with APEGBC (Association of Professional Engineers and Geoscientists of British Columbia). He has been an integral part of the Robert Allan Ltd. team for the past 5 years where he has primarily been involved in management of the production design team and design of vessel structures. Prior to joining Robert Allan Ltd., Dmitry worked 3 years as a Senior Structural Designer at Genoa Design International and 4 and a half years as a Naval Architect at Marine Technologies Ltd. in Russia. Dmitry obtained a Master’s Degree in Naval Architecture with a specialization in Design and Technical Operation of Ships from Kaliningrad State Technical University in 2002.

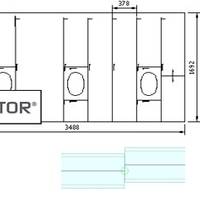

ShipConstructor Update Responds to New Needs

ShipConstructor 2014 R2.1, released from SSI, has been specifically designed to rapidly respond to emerging trends in ship design and engineering as identified by SSI's new Client Council program, the company said. "Both technology and industry requirements are evolving quickly so our clients continually need to adapt," explained SSI CTO Denis Morais. "SSI's Client Council program has been designed to address this by having focus groups of similar clients propose new features that SSI can quickly incorporate into our software.

Wärtsilä Seals and Bearings cover 90% of SWS Newbuilds

Wärtsilä is supplying air/oil lubricated sterntube seals and bearings to Chinese shipyard Shanghai Waigaoqiao Shipbuilding (SWS) for a series of new tankers under construction by SWS for Singapore-based Ocean Tankers. A complete Wärtsilä package of JMT Airguard seals, sterntube bearings, and shaftline bearings, was ordered in October and December 2006 for installation in the first of 12 Aframax tankers. "We have established a very good relationship with Shanghai Waigaoqiao Shipbuilding, which today is the largest commercial shipyard in China. Since 2001 we have supplied seals and bearings to SWS for 32 bulk carriers and 16 crude oil tankers," said Wärtsilä Seals and Bearings regional sales manager Adrian Higginbottom.