Global Bunker Measurers in Strategic Partnership

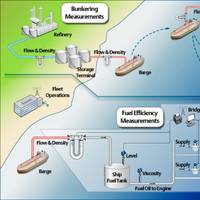

Emerson Process Management and SeaTec Repair Services announce a cooperative relationship to provide marine fuel measurement solutions, intended to help marine customers save in operating expense and ensure accurate billing. The cooperative relationship will offer marine customers no-hassle installation of Micro Motion ® fuel measurement solutions on a global scale. Emerson’s Micro Motion fuel measurement solutions provide accurate measurement of heavy fuel oil, in bunkering and control of fuel burn, which help customers save on operating expense and ensure accurate billing.

Progressive Barge Benefits From Bunker Measurement Solution

W&O and Emerson Process Management have announced that a Micro Motion MID-Certified (Measurement Instrument Directive) Marine Bunker Measurement Solution has been installed on a barge operated by Progressive Barge Line, Inc. in the Port of New Orleans, La. Emerson’s bunkering solution provides highly accurate, transparent bunker fuel deliveries. This installation by W&O on the 27,000-ton Progressive barge PBL2402 is the first in North America. Progressive Barge Line, Inc. (PBL)…

Emerson, Rederi AB Develop Flowmeters for Fuel Efficiency

Following a joint program by Rederi AB Transatlantic, Transas AB, and Emerson Process Management to develop an onboard solution for better control of marine fuel consumption, Rederi AB Transatlantic has installed Emerson’s Micro Motion Coriolis mass flowmeters on several ships in its fleet. The standard solution uses a compact Micro Motion F100-Series Coriolis sensor with a Model 1700 transmitter to provide highly accurate, traceable and transparent mass-based measurement of fuel oil. Using the MODBUS communications protocol, the mass flowmeter sends data to a fuel efficiency control system supplied by Transas AB in Sweden. This system, also called a Conning unit, collects information from the flowmeter and other onboard systems to help the crew optimize the operation of the ship.

New Bunkering System Passes Field Tests

Nautical Control Solutions (NCS) announced that Buffalo Marine Service of Houston successfully tested its FuelTrax bunkering system on a delivery of 1,500 metric tons of IFO 500 to Maersk Wyoming, a 292-meter container ship operated by Maersk Line, the liner shipping activity of the A.P. Moller – Maersk Group (MAERSKB:Copenhagen). The test took place on August 26, 2009 at Barbours Cut terminal at the Port of Houston. The crew of Buffalo 401k pumped at the rate of 250 metric tons per hour, with accuracy measured to less than 0.1% between the barge and the ship. Accuracy was verified by Maersk Wyoming’s own in-line mass flow meter. The FuelTrax-based system provides real-time measurement of bunker deliveries irrespective of product type, viscosity, or temperature.