Oil Sample Lab Results Help ID Responsible Party

The unified command consisting of the Coast Guard, New York State Department of Environmental Conservation, New Jersey Department of Environmental Protection, New York City Department of Environmental Protection, New York City Office of Emergency Management, and Monmouth County Department of Health, received oil sample lab results from the Coast Guard Marine Safety Laboratory Friday, linking together oil spill cleanup efforts in both New York and New Jersey.Vane Brothers Company, as represented by Gallagher Marine Systems, has been identified as the responsible party.

USCG Implements Handheld Technology for Onboard Oil Testing

With a motto of Always Ready, the United States Coast Guard (USCG) has 11 missions specified by law including drug and migrant interdiction; ports, waterways and coastal security; fishery patrols; search and rescue; and national defense. The USCG’s newest ships including 22 Fast Response Cutters (FRCs) recently entered service with 36 more on order and six new National Security Cutters (NSCs) with two more in the process of being built. Oil analysis plays a critical role in the…

IBIA Promotes Sensible Approach to Sulphur Testing

International Bunker Industry Association (IBIA) is continuing its efforts for IMO to adopt guidelines ahead of 2020 that will promote a uniform approach to fuel oil testing and reporting protocol for the verification of compliance with MARPOL Annex VI sulphur limits. Earlier this year, IBIA submitted two papers to the 5th session of the IMO’s Sub-Committee on Pollution Prevention and Response (PPR 5) proposing a way ahead on sulphur testing and compliance verification. Both papers will be forwarded to a PPR intersessional working group (ISWG) taking place at the IMO in July. In PPR 5/12/1, IBIA proposes establishing appropriate guidelines for verifying the sulphur content in fuel oil samples taken from ships’ fuel systems (in-use samples).

Kalmar Gloria Reachstackers Enter Asia-Pacific

Kalmar, part of Cargotec, is set to launch its highly acclaimed G-generation reachstackers, named Gloria, into the Asia-Pacific region. The much anticipated entry into APAC follows the successful introduction to European markets, where Kalmar's fifth generation reachstackers have been setting new standards in cargo handling performance. The launch will take place on 26 August in Shanghai, China. With thirty different Gloria models available, Kalmar offers the industry's widest range of reachstackers to meet all types of cargo handling applications. Developed to meet the critical demands of container, intermodal, barge and industrial handling market segments, Gloria provides the benchmark for productivity, operator comfort, safety and cost-efficiency.

Oil Test Detects Cold Corrosion

Parker Kittiwake, the global provider of asset control and protection technology, has announced a breakthrough in onboard cold corrosion testing with their new portable test kit. In less than five minutes per test, Parker Kittiwake’s Cold Corrosion Test Kit monitors specific levels of corroded iron in used cylinder oil. As growing numbers of ship owners and operators favor new generation engines to reduce fuel costs and meet environmental requirements, the problem of cold corrosion escalates.

What’s in Your Engine Oil?

Volvo Penta of the Americas is offering customers an Oil Analysis Program designed to make it easy to obtain expert diagnostics of engine oil. The program is available for all Volvo Penta diesel and gas engines. Engine oil analysis provides a basic driveline “health check” for an engine, yielding a wealth of information on what’s going on inside. With this information, you can plan your maintenance more effectively and reduce the risk of unplanned downtime and repair expenses. The process is fast and easy. Collect your oil sample and send it to a Volvo Penta laboratory.

Oil Discovered in Second Oman Exploration Well

Masirah Oil Limited has announced the successful reach of the well target depth in the second exploration well in Block 50 Oman to its final depth of >3,000 metres into the Cambrian formation. Hydrocarbons were discovered in several formations with good oil sample extracted. The well will undergo data acquisition before setting the completion for testing. The well was drilled using the independent leg cantilever jack-up drilling rig Aban VII. Mr Hans Lidgren, Chairman of Masirah…

Proper Engine Maintenance Leads to Significant Cost Savings

Engine Maintenance trumps a tough economy. Bypass oil filtration technology is one way to get there. For the past several years, ferry service and tugboat operators have had one eye on fuel costs and the other on the economy. But worry as they might, there’s not much, if anything, that operators can do to effect change to the economy or to reduce the price of fuel. What they can do, however, is effect change to reduce their company’s operating costs and that’s where proper engine maintenance can make a significant difference.

North American ECA – Today

On August 1, 2012, the North American Emissions Control Area (NAECA) took effect, mandating the use of 1.0% sulfur Heavy Fuel Oil (HFO) or residual fuel oil for ships within 200 miles of the continent of North America. California has mandated the use of distillate fuel when ships are within 24 miles of its coastline since July 1, 2009. Lessons learned from California’s experience with distillate fuels may benefit operators as the next phase of NAECA comes into effect (January 1…

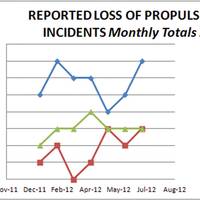

Propulsion: Optimizing Feed Rates For Crosshead Diesels

ExxonMobil introduced a program to optimize cylinder oil feed rates in low-speed (crosshead) diesel engines. The "Feed Rate Optimization" program is designed to help minimize operating expenses by analyzing scrapedown oil as a way to detect changes in the condition of an engine¹s cylinders. The program, which is designed to help customers find a balance between the cost of cylinder oil and the expense of wear-related cylinder maintenance, analyzes scrapedown oil collected from the engine’s scavenge space, a technique pioneered by ExxonMobil. It is designed to provide comprehensive laboratory testing and analysis of the oil sample, and offers onboard testing tools that enable ship’s engineers to quickly detect substantive changes in cylinder condition.

ExxonMobil Introduces Feed Rate Optimization Program

marine propulsion. changes in the condition of an engine¹s cylinders. technique pioneered by ExxonMobil. cylinder condition. Lubricants. maintenance and operating costs. . Signum Oil Analysis. before they occur, to include scrapedown testing. scrapedown oil. . Onboard testing. quickly analyze the current wear rate of each cylinder. engine's operating condition. . Quality oil. engine deposit and wear. rates are adopted. major engine manufacturers, including MAN B&W and Wärtsilä. onboard sample analysis is employed,² says Kjeld E. engineering services, MAN B&W Diesel A/S.

Engine Oil Analysis Kit Launched

Jet-Care International and its parent company Spectro Oil Analysis Co. Ltd. introduced a new engine oil analysis kit and service for the marine market that can save long delays and expensive repairs. "With proper monitoring of oil and fluid systems, marine operators can significantly reduce wear caused by contamination from sea water, fresh water, fuel dilution or the use of incorrect lubricants and save long delays and expensive repairs," says Spectro chief chemist Colin Stevens-Hoare. "In bigger vessels, oil sumps are so large the oil's never or rarely changed. Most operators try and clean the oil, but some are complacent, relying on their purification equipment to remove contaminants.