Book Review: Getting Down to It; 50 Years of Subsea Success in Norway

The Norwegian Continental Shelf’s journey from the very first basic marinized subsea trees to today’s complex and sophisticated subsea processing equipment has been a rapid, at times turbulent, but always remarkable.There are many engineers who have seen through that journey, from the first exploration wells using Norwegian rigs in the mid-1970s to today. One has now written the history of subsea technology in Norway and this year’s Underwater Technology Conference (UTC) has been chosen for its launch…

Subsea 7, OneSubsea Bag Gulf of Mexico Contract

Offshore oil services firm Subsea 7 has announced the award of a sizeable contract by Fieldwood Energy to Subsea Integration Alliance, a global partnership between Subsea 7 and OneSubsea, a Schlumberger company.The award is for the deepwater Katmai field development in the US Gulf of Mexico’s Green Canyon 40, said a press release from the company.This supplier-led integrated subsea development solution, combines OneSubsea’s subsea production systems (SPS) and Subsea 7’s subsea umbilicals, riser and flowline systems (SURF) expertise.The Subsea 7 scope includes project management, engineering, procurement, construction and installation of 40 km of pipe-in-pipe production flowline (12” outer pipe and 8” inner pipe)…

ABS Issues Subsea Processing Advisory

ABS has developed the Subsea Processing System (SPRS) Advisory that provides an overview of the SPRS and associated sub-systems that are currently available and addresses its technology maturity level.The advisory also describes the role of ABS as an independent classification society in the verification and validation of subsea processing technologies including new/unproven technologies through the ABS New Technology Qualification services.The advisory is the first in a series of publications planned by ABS over the next few years. Future publications will include guidance notes, advisories and white papers that provide insight on subsea processing technologies.Deepwater production remains an essential part of the global energy mix and economically viable projects continue to progress.

FPSOs Sit Unprecedentedly Idle

The 20 year four-fold growth pattern in the world’s FPSO fleet stalls out in 2016 with a record number of FPSOs idle and available for redeployment – or perhaps to be forced into other uses, lay up or scrap. FPSO redeployments typically are far more complex, costly and risky than for (say) drillships and yet the need for redeploying idle FPSOs is now in the forefront of the industry like never before as FPSO owners also have to face the worst ever down market for their equipment and services.

First Subsea Wet Gas Compressor Installed

After several years of technology development, construction and testing the first subsea wet gas compressor in the world is now installed at the Gullfaks C platform in the North Sea. In May and June Gullfaks subsea compressor project (GSC) completed successful structure and module installation campaigns for the subsea station. The compressors were installed at the end of June. Subsea wet gas compression at Gullfaks C will add 22 million barrels of oil equivalent, and extend plateau production by about two years. “The installation campaigns have been successfully performed by Subsea Seven,” says project manager Bjørn Birkeland. The project has now entered the last phase, testing and preparing for hand-over and start-up in the last quarter of this year.

Aker, Fjords Join Forces

Aker Solutions and Fjords Processing have formed an alliance to develop technology and capabilities for advanced, cost-effective wellstream separation and treatment solutions for the subsea and topside oil and gas industry. The WellSep alliance will apply Aker Solutions' subsea processing experience and testing facilities and Fjords' topside and onshore separation technologies to provide complete solutions. "This is a great opportunity to further develop our key technologies with one of our most important partners, Aker Solutions," said Rune Fantoft, chief executive officer of Fjords Processing. "The alliance will further strengthen our wellstream separation technology portfolio, testing and in-house capabilities," said Alan Brunnen, head of subsea at Aker Solutions.

GE Opens Global R&D Center in Brazil

General Electric today announced the opening of the $500 million Brazil Technology Center that will focus on developing advanced subsea oil and gas technology. The center, GE’s first in Latin America, will be a hub for engagement and collaboration with GE’s customers in the region and is expected to employ 400 researchers in the future. In the twentieth century, one of mankind’s greatest feats was successfully landing on the moon more than 235,000 miles from earth. In the 21st century, mankind’s greatest feat may well be securing the world’s energy future for the next few centuries. Subsea engineers often say that it is actually more difficult to put a machine 10,000 feet under the sea than send a rocket to the moon.

Statoil, DNV GL Drive Subsea Factory Interface Standardization

Statoil has entered into an agreement with DNV GL to establish an industrial cooperation to introduce an international industry standard for subsea process technology. DNV GL will lead a joint industry project (JIP) with important subsea operators to find industrial standards which will make it more profitable to develop larger projects with subsea processing technology. Today, subsea developments are characterized by tailor-made solutions. Subsea pumps have been used in many oil fields…

New Subsea Report on Tech, Safety and Trends

DNV GL has issued the report ‘Subsea – Technology Developments, Incidents and Future Trends’ on behalf of the Norwegian Petroleum Safety Authority. “The ongoing increase in technology enhancement and the number of worldwide subsea field developments will demand greater focus on a number of issues. The report aims to raise awareness and share knowledge within safety, industry cooperation, degradation mechanisms, failure modes, monitoring, integrity management and incident-related information,” said Bjørn Søgård, DNV GL’s segment director for subsea technology. The oil and gas industry’s drive to develop more cost-efficient ways to produce, process and transport oil and gas offshore has in the past few years led to tremendous technology developments on subsea technology.

Brazil Offshore: Petrobras & Subsea Engineering

Brazil’s Petrobras has been one of the leading players in deepwater, subsea development projects since the turn of the century. These projects include pre-salt and post-salt plays, which require extensive and complex subsea engineering and construction efforts. It would be impossible for Petrobras to develop all of its projects alone, therefore much is done by specialized companies, mostly of foreign origin. “We could not have advanced in this project (pre-salt) conventionally, developing the production individually. We needed a global vision of the projects, starting from a high level plan,” said José Formigli, Petrobras’ Executive Director of E&P, speaking of the primary plan for the development of the pre-salt at the Santos Basin, the Plansal, which was created in 2008.

Statoil, ABB Enter Subsea Technology Agreement

Statoil and ABB have entered an agreement to develop solutions for subsea electrical power transmission, distribution and power conversion systems for water depths down to 3,000 meters and over long distances. The agreement is in the form of a cost-shared joint industrial program (JIP) led by Statoil on behalf of other participating oil companies, with ABB as the technology developer. The agreement follows a large subsea electrification study executed jointly by Statoil and ABB during 2012. “The JIP will develop technologies needed to provide electrical power to subsea pumps, electrical submersible pumps and subsea gas compressors for projects on the Norwegian continental shelf…

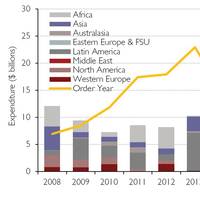

Subsea Vessel Market Poised For Increase in Demand

The subsea vessel operations market is poised to see an increase in demand in the near term with day rates for some vessels set to increase. Between 2013 and 2017, Douglas-Westwood (DW) forecast $106 billion of expenditure on subsea vessel operations – an increase of 54% over the preceding five-year period. Global demand is expected to increase 23% compared to the previous five years. The rate of increase in expenditure is expected to be higher than the growth in vessel days,…

Subsea Hardware Spending to Double to $124 Billion

Douglas-Westwood (DW) forecast subsea hardware spending is set to double to $124 billion during 2013-2017 compared to the preceding five-year period. The new third edition of Douglas-Westwood’s Subsea Hardware Market Forecast has launched analyses the market through to 2017, examining the key activity trends to provide detailed insight for major players and new entrants alike. “The prospects for the subsea hardware sector look good, however, players will face significant challenges over the forecast period,” said report lead author Angela MacCormack, an example is Brazil which accounts for 14% of our forecast subsea Capex. Project execution is a major issue for Petrobras with 70% local content requirements and engineer shortages placing pressure on the supply chain…

Floating Production

Douglas-Westwood forecast that between 2013 and 2017, $91bn will be spent on floating production systems (FPS) – an increase of 100% over the preceding five-year period. A total of 121 floating production units are forecast to be installed – a 37% increase. This growth is driven by multiple factors, such as a larger proportion of newbuilds and conversions compared to redeployments, a greater degree of local content which often results in a higher cost base and general offshore industry cost inflation.

Floating Production Expenditure set to Double

Douglas-Westwood forecast that between 2013 and 2017, $91bn will be spent on floating production systems (FPS) – an increase of 100% over the preceding five-year period. A total of 121 floating production units are forecast to be installed – a 37% increase. This growth is driven by multiple factors, such as a larger proportion of newbuilds and conversions compared to redeployments, a greater degree of local content which often results in a higher cost base and general offshore industry cost inflation.

Subsea J/V Launched by Cameron & Schlumberger

The joint venture company, OneSubsea, is to manufacture and develop products, systems and services for the subsea oil and gas market. This new company intends to offer a step change in reservoir recovery for the subsea oil and gas industry through integration and optimization of the entire production system over the life of the field. The integration of the production system will be accomplished by combining superior reservoir knowledge and wellbore technologies, with industry leading subsea technologies, all together delivering enhanced productivity, reliability and integrity. Cameron and Schlumberger have 60/40 ownership of the joint venture, respectively, and the transaction is subject to regulatory approvals and other customary closing conditions.

FMC Supplies Separation System for Petrobras

FMC Technologies, Inc. (NYSE: FTI) announced that it has been awarded a contract by Petrobras (NYSE: PBR) (NYSE:PBRA) to supply a subsea separation system for the Marlim field, located in the Campos Basin, offshore Brazil. The contract is valued at approximately $90m in revenue to FMC Technologies. FMC's scope of supply consists of a subsea separation and pumping system. The subsea separation module will separate heavy oil, gas, sand and water at a water depth of approximately 2,950 feet (900 meters). The system will apply FMC's separation and sand management technologies, utilizing a novel pipe separator design, licensed and developed in cooperation with StatoilHydro.

GE Oil & Gas Awarded Statoilhydro Contract

GE Oil & Gas announced that it has been awarded a five-year contract to deliver Subsea Operations Services (SOS) to StatoilHydro, the Norwegian based oil and gas company. The contract has an estimated value of between $25- $30m per year and will be managed by GE Oil & Gas in Dusavik, Stavanger, Norway. The scope of services to be provided under the agreement relate mainly to the installation and operations phases of StatoilHydro’s subsea fields, including: engineering, procurement, the production of equipment and tools, and electro and mechanical workshop services for corrective and planned maintenance in subsea drilling. Servicing and…

FMC Tech to Acquire 45% of Schilling Robotics

FMC Technologies, Inc. (NYSE: FTI) and Schilling Robotics announced that they have entered into a definitive agreement whereby FMC Technologies will acquire a 45% interest in Schilling Robotics LLC for $116m in a transaction expected to close no later than December 31, 2008. The acquisition is expected to be accretive to FMC Technologies’ earnings per share in 2009. FMC Technologies is a manufacturer and supplier of subsea production systems. Schilling Robotics is a producer of ROVs (remotely operated vehicles), ROV manipulator systems, control systems, and other technology equipment and services for oil and gas subsea exploration and production. FMC Technologies Chairman, President and CEO, Peter D.

FMC Technologies Awards Subsea Frame Agreement

FMC Technologies, Inc. has signed a new five-year frame agreement with Statoil to provide subsea equipment and associated services for the North Sea and potential international developments. The agreement also includes two options to extend the contract for two additional years each. FMC Technologies is one of two subsea suppliers who would receive orders against this frame agreement. Statoil estimates the total value of all orders to be placed under the frame agreement to be within a range of $2.6 to $4.4b. Equipment and services related to this frame agreement will be manufactured and supplied from FMC’s Kongsberg, Norway facility. The award of this frame agreement does not impact FMC’s inbound or backlog.