KEYS Azalea Completes its First Ship-to-Ship LNG Bunkering

Japan’s first dual-fuel LNG bunkering vessel KEYS Azalea has completed its first ship-to-ship LNG bunkering in Western Japan.The vessel - owned and operated by KEYS Bunkering West Japan Corporation, a joint venture established by Kyushu Electric Power, NYK Line, Itochu Enex, and Saibu Gas - bunkered LNG for the car and truck carrier Daisy Leader 2 at the Port of HiroshimaKEYS Azalea was delivered to KEYS Bunkering West Japan Corporation earlier in April. It is equipped with a…

Japan’s First Dual-Fuel LNG Bunkering Vessel Delivered to Industry Partners

KEYS Bunkering West Japan Corporation - a joint venture established by Kyushu Electric Power, NYK Line, Itochu Enex, and Saibu Gas – has taken delivery of KEYS Azalea vessel, said to be Japan’s first LNG bunkering vessel equipped with a dual-fuel engine.The delivery ceremony for the vessel was held on March 28, 2024, at the Yamatomachi Shipyard of Mitsubishi Shipbuilding in Japan’s Yamaguchi Prefecture.KEYS Azalea will provide domestic coastal transport of LNG to consumers in the Kyushu and Setouchi areas and LNG bunkering for oceangoing vessels calling ports in the region.Mitsubishi Launches…

Mitsubishi Launches, Christens LNG Bunkering Vessel

Mitsubishi Shipbuilding Co., Ltd., a Mitsubishi Heavy Industries (MHI) Group company based in Yokohama, today held a christening and launch ceremony for a liquefied natural gas (LNG) bunkering vessel, the first to operate in western Japan, built under contract for KEYS Bunkering West Japan Co., Ltd. The ceremony was conducted at the Enoura Plant at MHI's Shimonoseki Shipyard & Machinery Works in Yamaguchi Prefecture. The new vessel, christened KEYS Azalea, is scheduled for handover…

Mitsubishi Shipbuilding to Build LNG Bunkering Vessel

Mitsubishi Shipbuilding Co. signed a contract with KEYS Bunkering West Japan Co., Ltd. for construction of a liquefied natural gas (LNG) bunkering vessel, the first to operate in western Japan. The vessel will be built at the Enoura Plant at MHI’s Shimonoseki Shipyard & Machinery Works in Yamaguchi Prefecture, with completion and handover scheduled for March 2024.KEYS Bunkering West Japan is a joint venture company established in February 2022 to supply LNG fuel for ships in the Kyushu and Setouchi Regions…

MOL's Propeller Boss Cap Fins earns Guinness World Record Title

Mitsui O.S.K. Lines, Ltd. announced that its Propeller Boss Cap Fins (PBCF), sold by its group company MOL Techno-Trade, Ltd. was certified as the “Best-selling Energy-Saving Ship Appendage Brand (Cumulative)”, by Guinness World Records, and received the official certificate on December 23, 2021.This award is based on the cumulative 3,748 PBCFs sold (the sales record with 3,516 vessels including twin-screw vessels equipped with PBCF) as of the end of December 2020.PBCF was co-developed by MOL, West Japan Fluid Engineering Laboratory Co., Ltd., and Nakashima Propeller Co., Ltd.

Japan's JFE to Invest $363,3M in New Offshore Wind Monopile Plants

Japan's JFE Engineering Corporation is set to build a factory for the construction of monopile foundations and transition pieces for the offshore wind industry. The company also has plans to build jacket-type foundations in the future."The monopile foundation consists of a transition piece for connecting the monopile as a support and the wind turbine tower and is an extremely thick, large-diameter, long super-heavy object, which is difficult to manufacture at existing factories in Japan.

MOL Techno-Trade in Green Initiative

Japanese shipping giant Mitsui O.S.K. Lines (MOL) announced that its group company MOL Techno-Trade has joined a Green Award Program aimed at promoting high-quality shipping.The program is run by the nonprofit Green Award Foundation, which was established with the objectives of protecting the marine environment and enhancing safe operation.The program aims to improve the quality of vessels and mariners and protect the marine environment by certifying vessels for excellence in safety and low environmental impact. Companies that share the foundation's goals support them by providing incentives.Eleven MOL Group-operated vessels have earned certification from the Green Award Foundation.

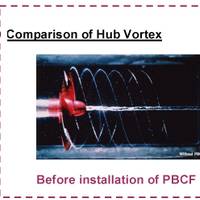

MOL's PBCF Reduces 3-5% in Fuel Consumption

Mitsui O.S.K. Lines (MOL) announced that its jointly developed Propeller Boss Cap Fins (PBCF) received the 2017 Nikkei Global Environmental Technology Award, which is presented by Nikkei Inc. The PBCF, which is a device that improves propeller efficiency by breaking up the hub vortex generated behind the rotating propeller and offers an energy savings of around 3-5% compared to similar vessels not equipped with the PBCF, was co-developed by MOL, West Japan Fluid Engineering Laboratory Co., Ltd., and Nakashima Propeller Co., Ltd. (called Mikado Propeller Co., Ltd. at the time), and is being sold by MOL Techno-Trade, Ltd. The PBCF has been sold for more than 3,200 vessels all over the world since 1987, when it started sales of the conventional PBCF.

Vancouver Port Selects “PBCF” as Equipment Designated

Mitsui O.S.K. Lines, Ltd. today announced that Propeller Boss Cap Fins (PBCF) was selected as a vessel quieting technology by the EcoAction Program implemented by Port of Vancouver, Canada. PBCF was jointly developed by MOL, West Japan Fluid Engineering Laboratory Co., Ltd. and Nakashima Propeller Co., Ltd. (Note 1), and is being sold by MOL Techno-Trade, Ltd. The Vancouver Fraser Port Authority’s EcoAction Program offers discounted harbour due rate to vessels that have implemented voluntary emission reduction measures and other environmental practices. As of January 1, 2017, vessels equipped with PBCF and transiting to the Port of Vancouver will be eligible for bronze level recognition and a 23% discount in harbour dues.

APL Introduce New Intra-Asia Service

APL introduce a new weekly service to enhance its network coverage in East Asia, with connections to APLs global network. The new Japan Thailand 2 (JT2) service is operated through a vessel sharing agreement with Hanjin Shipping with three vessels of 1700 TEU nominal capacity each. The new service port rotation is: Osaka Kobe - Hibiki Hakata Kaohsiung Chiwan Laem Chabang Hong Kong Kaohsiung Osaka. The first northbound sailing will begin on 21st December 2012 from Laem Chabang. The first southbound sailing will begin on 24th December 2012 from Osaka. APL is a global container shipping business offering more than 80 weekly services and more than 500 calls at more than 140 ports worldwide. It combines world-class intermodal operations with leading-edge IT and e-commerce.

Energy-Saving Propeller Boss Cap Fins System

Mitsui O.S.K. Lines, Ltd. (MOL; President: Koichi Muto) and MOL Techno-Trade, Ltd. (MOL Tech; President: Hidehiro Harada) today announced that the energy-saving Propeller Boss Cap Fins (PBCF), developed by MOL, West Japan Fluid Engineering Laboratory Co., Ltd., and Mikado Japan, Ltd., and sold by MOL Tech, has now been ordered for 2,000 vessels worldwide. The PBCF is an energy-saving device attached to the propellers of a vessel. It breaks up the hub vortex generated behind the rotating propeller…

Propulsion News

Propeller Boss Cap Fins (PBCF) is a propeller enhancing device, which is designed to cut fuel consumption and exhaust gases by up to five percent while incurring no additional maintenance cost once installed. The unit, according to H. Yumoto Manager of PBCF Div. Mitsui O.S.K. Techno Trade, Ltd., is now operational on 720 ship worldwide. The PBCF rectifies the propeller hub vortex and recovers rotational energy otherwise lost in the propeller slip stream. Increasing propeller thrust by over one percent and reducing propeller torque by over three percent, the PBCF reportedly results in fuel savings of up to five percent or compared to vessels operating at equivalent speeds but without the PBCF, alternatively, a 1.5 percent increase in speed at the same engine output.