US Great Lakes Fleet Invests $83 Million in Maintenance

This year, U.S.-flagged Great Lakes shipping companies will spend nearly $83 million for annual vessel maintenance and upgrades, according to trade group the Lake Carriers’ Association (LCA).The winter ship repair work programs are performed annually to help keep iron ore, stone and cement moving on the Great Lakes during the nine-month operating season from March through January, when the Soo Locks are open for business. Work will range from engine and navigation system upgrades…

Kongsberg Propulsion for Norwind Offshore's New Vessels

Norwind Offshore, a new offshore wind-focused ship-owning company recently established in Norway by Farstad, Volstad, and Kleven, will install Kongsberg equipment to its two new Commissioning Service Operations Vessels (CSOVs), to be built by VARD."Kongsberg Maritime’s scope of delivery encompasses a combination of systems which will enable the operator to maximize operational windows whilst minimizing overall energy consumption," Kongsberg said."Key to this is the propulsion technology…

Norwegian Cruise Eyes Return to Profitability in H2 2022

Norwegian Cruise Line Holdings Ltd on Wednesday forecast a return to profitability in the second half of 2022, as the U.S. travel and tourism industry claws back from the impact of the COVID-19 pandemic.Cruise operators recorded billion-dollar losses last year as many ships anchored offshore without passengers, but pent-up demand for leisure travel and roll-out of COVID-19 vaccines have helped cruise lines pull thousands of guests again.U.S. health officials earlier this year…

Marine Diesel Engine Market to Grow 3.9%

The global marine diesel engine market is estimated to grow at CAGR above 3.9% over the forecast time frame and reach the market value around US$ 8.1 billion by 2026.The worldwide market for marine diesel engines has expanded mainly as shipping industry needs to decrease carbon emissions, said Acumen Research and Consulting.The shipping industry focuses on developing higher-efficient diesel engines that use less diesel while offering more ship propulsion. However, the latest shipping and shipbuilding downturn has impaired the market.Shipbuilding orders decreased with lower shipping prices. Recovery is anticipated during the forecast period…

MarineMTS Strikes Equity Deal with SRH Marine Electronics

Stonehaven-based marine technology company MarineMTS has struck an equity funding deal with SRH Marine SAIT (trading as SRH Marine Electronics). The deal will see the North-east business benefit from a multimillion dollar funding package, and through SRH Marine’s existing customer base, unlock access to approximately 15,000 vessels which could benefit from MarineMTS’ latest ‘Silverbox’ technology. The resultant trade could net the business in the region of $16 million in licensing…

S.Korean Refiners Look to Cash in on 2020 Mandate

Three refiners to spend more than $5 bln to upgrade or add units. South Korean refiners are planning to spend over $5 billion on plant upgrades in response to tighter rules on shipping fuel, boosting production of low-sulphur fuel oil as well as other high-end products. The refiners hope the investment, which comes ahead of the 2020 introduction of the new rules, will make them one of the biggest beneficiaries of the new regulations, with many competitors still waiting to commit to new spending. "Not many refiners are doing so. Korean refiners are investing proactively," said Hwang Yu-sik, an analyst at NH Investment & Securities. In 2016…

China Pledges Support for Domestic Shipbuilders

China aims to capture up to 40 percent of the global high-end marine equipment market over the years through 2020 while reforming and supporting its money-losing shipbuilding industry, the government said on Thursday. The pledges were laid out in a statement published by six ministries on the website of the Ministry of Industry and Information Technology. The statement broadly outlined their plans for Chinese shipbuilding over 2016-2020. The global shipping industry is suffering from a severe downturn that has sapped demand for new vessels. Many shipyards in China, which build mainly mid-to-low-end vessels such as dry bulk carriers, have shut down as a result.

Mastry Helps OEMs Achieve EPA Compliance

Tier 4 EPA regulations create unprecedented challenges for many OEMs, as they require extensive testing to ensure end products are compliant. Mastry Engine Center now offers design and performance analysis services for its OEM customers to help with this hurdle. The diesel engine specialist said it can also streamline business for those who use its engine brands for their own equipment, with its sub-assembly and private label options. Mastry draws from more than 50 years of industrial and marine diesel engine experience to help its customers succeed.

Gas2 Tests GTL Process Technology

Gas reforming company Gas2 said it has achieved a second milestone at its 3 bpd (barrels per day) Wilton Research Center pilot plant in Teesside, U.K. as it develops a new generation of natural gas-to-liquids (GTL) process technology which has the potential to deliver lower cost solutions for small scale plants. By successfully commissioning and starting-up the Fischer Tropsch (FT) reactor, using syngas produced in the syngas reactor, the company has produced hydrocarbon liquids.

China Shipbuilder Hit by Forex Losses on Contracts

Yangzijiang Shipbuilding Holdings Ltd. China’s second-biggest private shipyard, posted a 7.6 percent decline in second-quarter profit because of higher tax and foreign exchange loss on contracts done in euros, reports Bloomberg. Citing a company statement to the Singapore Stock Exchange, Bloomberg say that Net income in the three months ended June dropped to 812 million yuan ($133 million) from 878 million yuan a year ago, while sales rose 12 percent to 4.42 billion yuan. Yangzijiang is among companies diversifying into offshore drilling and production as demand for new bulk vessels decline. The government has urged financial support…

Gas2 Gas-to-Liquids (GTL) Pilot Plant on Target

Scottish gas reforming company Gas2 is on track with the development of the next generation of natural gas-to-liquids (GTL) technology with a test program that is underway at its newly constructed pilot reactor plant. The £5 million plant, located at the specialist petrochemical research Wilton Center, Teeside, has been designed to validate five years of laboratory testing and computational fluid dynamic modeling. It has been built on time and on budget and is on schedule with an extensive test program that will continue throughout 2013. Aberdeen-based Gas2 has developed a catalytic ceramic based porous membrane (pMRTM) that is used in its gas reforming (Syngas) reactors and fluid forming (Fischer Tropsch) reactors to create liquid hydrocarbons.

OSX: Full Speed Ahead on Mammoth Shipyard Project

Danilo Souza Baptista, OSX’s Director of Naval Construction, sat with MR Contributing Editor Claudio Paschoa at EBX Group’s new HQ in downtown Rio de Janeiro, in a meeting room overlooking Guanabara Bay with Sugar Loaf Mountain as a backdrop, to discuss its ambitious yet realistic vision to create one of the largest, most efficient shipyards in the Americas, as well as its Integrated Service Solution to the meet offshore O&G needs. OSX is a relatively new company, founded by the EBX Group in 2009. The EBX Group, is a holding composed of several companies active in different industries such as mining, oil & gas, logistics, real estate, among others.

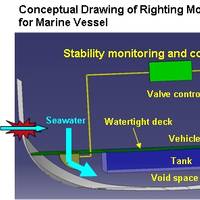

MHI System Enhances Stability, Reduces Risk

MHI Develops System to Enhance Damage Stability of Ships To Reduce Capsizing Risk: Response to Revised SOLAS Convention; First Order for Vessel with New System Placed by Nippon Shipping. Mitsubishi Heavy Industries, Ltd. (MHI) has developed a system to enhance the damage stability of ships, enabling reduction in capsizing risk, as well as a roll-on/roll-off (RO/RO) ship* equipped with the new system. The company has already received an order for the newly equipped vessel from Nippon Shipping Co., Ltd., a group company of Nippon Express Co., Ltd.

Wärtsilä: Catalytic Converters for Multipurpose Icebreakers

Wärtsilä was contracted by Finland-based Arctia Offshore Oy to carry out modification work to two of the company's vessels. The contract was signed in September 2011. The turnkey project involves the fitting of combined Wärtsilä NOx Reducer (NOR) and Oxidation Catalysts (OXI) to the MSV Fennica and MSV Nordica, both of which are multi-functional vessels based on a modified icebreaker design. The ships will also be converted to enable the use of Ultra Low Sulphur Diesel fuel. When this conversion work is completed…

Ship Naming Ceremony is held for Sinopacific's First Fabricated Ship

Ningbo, April 29, 2011 —— On the morning of 29 April, Sinopacific Shipbuilding Group, China’s leading private shipbuilding enterprise held the ship naming ceremony at its Zhejiang Shipyard for GPA696, the global first fabricated model of Offshore Support Vessel(OSV) built for France’s Bourbon Company. Afterwards, a sea trial event was also held for another global first fabricated OSV, the SX130. Attending this event were Ningbo Mayor Liu Qi, Sinopacific Shipbuilding Group Chairman and CEO Simon Liang…

Markey Machinery Seeking Area Partner

Markey Machinery Company, Inc (USA) is actively seeking a partner in the South Pacific area. This partner will manufacture and help support machines designed and carrying the Markey brand. An opportunity exists for the right company to produce winches, windlasses, and capstans of the highest quality standards while serving the growing needs of the Australian-region market and demands exceeding our factory production capacity. Markey’s partners have established facilities, a stable workforce, and production processes oriented toward low rate (prototype) manufacturing. Their facilities include support staff with modern computer/communication resources, heavy lift handling equipment, clean assembly areas, and proximity to ocean shipping terminals.

Navy’s Eco-friendly Waste Disposal System

An environmentally friendly and cost-effective solution to the disposal of oily sludge waste has been developed by engineers, microbiologists, and chemists from Naval Facilities Engineering Command Hawaii (NAVFAC) Hawaii and NAVFAC Engineering Service Center (ESC). The solution makes it possible to remediate oily sludge waste at Pearl Harbor instead of shipping it to the mainland for disposal, which is a large cost burden and liability for the Navy. Remediating the waste is also a sustainable practice. Natural elements and processes are used, and the by-products of the remediation are natural and harmless to the environment. The oily sludge waste remediation project began as a pilot study in 2004 at the Bilge Water/Oily Waste Treatment Facility at Pearl Harbor.

Hempel Records Strong Year

Hempel in 2006 was able to take advantage of its leading market segment positions, continuing sustained growth to deliver a 19 percent increase in revenue versus 2005. The Hempel revenue figure was a new record level of EUR 780 million. Operating profit was up 36% to EUR 61 million from EUR 45 million and net profit was up 23% to EUR 37 million from 30 million for the same period last year. volumes in litres by 9% over the previous year. single year of 244 million litres for Hempel. The Protective business again in 2006 showed very encouraging growth in all markets, up 30% over 2005. Protective growth was especially strong within the Oil & Gas, and Wind segments, areas where Hempel has a lead position. 2006 with a 12% increase in sales.

New Rolling Mill Inaugurated at Fundia Nedstaal

The new rolling line at Fundia Nedstaal B.V.’s rolling mill was inaugurated in the Netherlands on Wednesday. The wire rod production of the company has now been centralised in a single combi mill instead of the previous two rolling lines. than before. President and CEO Mikko Kivimäki. at the rolling mill, and decreases maintenance costs. water. a year. line is 70 metres per second, i.e. 250 km/h. main installations were carried out in May and June. in the line. The total cost of the investment is EUR 11 million. end products for the automotive and engineering industry. such as adjustable wrenches or pliers. Together with Fundia Wire in Finland, Fundia Nedstaal B.V. ball bearing wire rods in Europe. European producer of valve spring wires. people. products.

ConocoPhillips Reports 1Q Results

ConocoPhillips reported first-quarter net income of $3,291 million, or $2.34 per share, compared to $2,912 million, or $2.05 per share, for the same quarter in 2005. Total revenues were $47.9b, versus $38.9 billion a year ago. During the quarter, the company reinvested 141 percent of its net income into the development of oil and gas resources and its global refining business, excluding the acquisition of Burlington Resources. are pleased with the progress toward integrating the combined companies,” said Jim Mulva, chairman and chief executive officer. “This transaction establishes ConocoPhillips as the leading natural gas producer in North America, with a portfolio comprised mainly of high-quality, long-life natural gas reserves.