WEG to Showcase Drive Solutions at SMM

WEG, a global supplier of drive systems, will showcase its range of systems for the shipbuilding and offshore industry at this year’s SMM (Shipbuilding, Machinery & Marine Technology Fair) in Hamburg. From September 9-12, visitors to Stand 303 in Hall B6 can learn more about WEG’s standard and special drive systems designed for ships and other on-board support tasks. The product portfolio ranges from low and high voltage motors to generators, frequency inverters and low voltage switching equipment.

Although the current European ErP Directive does not apply to motors on ships, increasing energy efficiency is becoming a top priority in the industry. Energy efficient drive systems offer ships - particularly cruise ships - economic benefits and the opportunity to market themselves as “Green” and more environmentally friendly. With this in mind, WEG said it is positioning itself as a pioneering manufacturer of W22 standard motors for the maritime market with equipment available in all the current efficiency classes from IE1 up to IE4 levels.

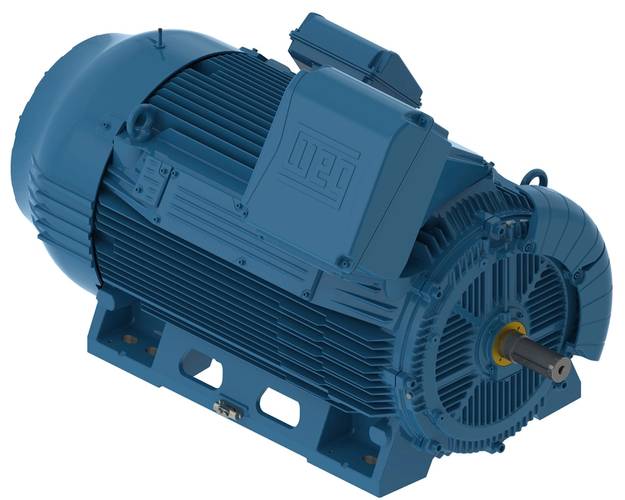

Among WEG’s core products for low-voltage maritime applications on display is the W22 motor range, which includes the W22x motors for potentially explosive atmospheres. These motors offer ship and machinery builders low operating costs and a high level of reliability and energy efficiency. Additionally, these compact cast iron motors are extremely robust and easy to maintain. Their modular design, which also ensures very low noise and vibration levels, enables them to be used flexibly for a variety of applications across the vessel, including hydraulic steering gears, ballast pumps, fresh water condensers, extinguishers, sewage and cooling water pumps, bilge pumps, drinking water and wastewater pumps and air conditioning and ventilation systems.

Other product highlights include the new compact standard W50 motors. With high power density and reliability, these are particularly suitable for pump, compressor and ventilator applications in the harshest environments. The 2- to 12-pole motors cover a power range of 75 to 1,250 kW while ensuring low noise and vibration levels. They are available in protection classes from IP55 to IP66 and cooled in accordance with IC-411 complying with DIN EN 60034-6. Additionally, the stiff motor shaft eliminates speed restrictions due to critical internal vibrations at motor speeds up to 3,000 rpm at 50Hz and 3,600 at 60Hz in frequency inverter operation.

The portfolio of WEG frequency inverters also includes special variants developed for Heating, Ventilation and Air Conditioning systems (HVAC), such as the CFW501 or the CFW701 with a bypass function for redundant motor operation. At SMM, WEG will also present the modular water-cooled CFW11W frequency inverter, which meets all the requirements of the shipping and offshore industries. The inverter enables feedback-free vector control or field-oriented motor control with speed sensor feedback for the highest speed and torque accuracy. Thus, the motor can be operated with high precision almost up to breakdown torque, even at low revolutions. Additionally, all functions necessary for the effective protection of low voltage motors are integrated into the equipment. As such, WEG’s inverters are suitable for a wide range of on-board tasks, including winch drives, lifting equipment and diesel-electric drives with up to 2.8 MW output, for which high accuracy and energy savings are in great demand.

“WEG is one of the few global companies to develop, manufacture and test both electric motors and transmissions, as well as automation components such as inverters,” says Marek Lukaszczyk, European Marketing Manager for WEG. “This enables us to act flexibly to meet the industry’s special requirements and offer bespoke solutions for a variety of applications. These range from traditional pole-switchable or modern fully-automated drive concepts for anchor and mooring winches to space-saving water jacket-cooled motors for rudder or propeller equipment in the high voltage range.”

weg.net