Port of Indiana-Mt. Vernon Makes ‘Next Generation’ Terminal Upgrades

A recently completed a $2 million capital improvement project aims to attract more cargo to one of the nation’s largest inland ports.Situated 153 miles from the confluence of the Ohio and Mississippi Rivers, the Port of Indiana-Mount Vernon connects the Ohio River Valley region’s agriculture, coal and manufacturing industries to the rest of the world via year-round access to the Gulf of Mexico and Great Lakes through the inland waterways system.Each year, more than 3,600 barges…

ABS Launches Liquefied Gas Tank Barge Guide

ABS Launches New Guide for Liquefied Gas Tank Barges with Remote Control and Monitoring of Essential Systems; outlines requirements for design and construction of unmanned barges equipped with various degrees of automation. ABS released guidance to assist shipyards and barge operators: The Guide for Building and Classing Liquefied Gas Tank Barges with Remote Control and Monitoring of Essential Systems.The Guide provides requirements for the design and construction of barges equipped with various degrees of automation…

Robert Allan Ltd.: The Place that Launched 1,000 Tugs

Over the last few years, as the design output from Robert Allan Ltd. to the global tugboat community began to border on the prodigious, we were often asked, “How many tugs has your company designed?” Until very recently we really did not have a good handle on that number, so the answer was usually either “a lot” or “many hundreds”, neither of which were particularly illuminating. So a search was begun late in 2016 to review our archives and try to determine the tug tally much more precisely. Would we rival Helen? Where did it all begin?

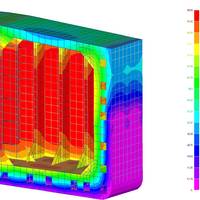

Meeting New Heated Cargo Vessel Regs

With the publication of the 2015 Rules for Building and Classing Steel Barges, ABS has amended the rules to require the submittal of a steady state temperature distribution for Oil Tank Barges that carry heated cargos at temperatures greater than 50°C (122°F) and a structural assessment to determine the resulting thermal stresses in barges where the steel temperature is expected to exceeds 50°C (122°F). While similar requirements have been in place for several years for chemical tank barges…

Moran Iron Works Awarded Barge Building Contract

Moran Iron Works (MIW) was recently awarded a contract to build two ocean going deck barges for Durocher Marine, a division of Kokosing Construction Co., based in Cheboygan, Michigan. The two deck barges will be 180’ X 54’ X 12’ with 2,500 lb/ft2 deck strength and 2,400 short ton cargo capacity. They will be built in accordance with International Maritime Organization (IMO), American Bureau of Shipping (ABS), and United States Coast Guard (USCG) regulations and classifications. The barges will follow ABS rules for building and classing steel barges for offshore service. They will be classed as ABS A1 Ocean Service Deck Barges and will have an International Load Line Certificate.

Responding to “The Articulated Tug Barge (ATB) Quandary”

I read with great dismay, the article that appeared in your magazine’s February 2013 issue, entitled “THE ARTICULATED TUG BARGE (ATB) QUANDRY”. noun, plural quandaries : a state of perplexity or uncertainty, especially as to what to do; dilemma. There is no dilemma involving AT/B’s present in the coastwise or ocean transportation marketplace. AT/B’s are indeed increasingly supplanting ships in the Jones Act coastal trade. It is a trend that is slowly beginning to spread to coastwise transport in other regions of the world as well.

Anyone Want to Restore a Tugboat?

You'd think it would be easy to start a tugboat museum. First, get an old tugboat. Clean-up some rust with a pad of coarse steel wool, slap-on a coat of paint, and presto, you're ready to sit in the booth and sell tickets. Everyone would applaud your efforts because, first, everyone loves tugboats and all they represent - solid construction and earnest purpose, hard work and benevolent contributions to civilization. And second, because old tugboats, all spiffied-up, are handsome sights, an alluring environmental decoration wherever they're found. And third, because the design of tugboats, like most of society's tools, has undergone great change, and the old ones are dying-off fast. You'd think everyone would support your labors at preserving a noble cultural heritage.

USCG "Paint Floats" Make Arduous Task Easier, More Environmentally Sound

The U.S. Coast Guard uses four small steel barges specifically engineered to provide a safe working platform and reduction in pollutants from painting operations during routine maintenance of Coast Guard Cutters. Gone are the days of the staging or boson chair rigged over the side with a crew member wielding chipping iron and paint roller. The U.S. Coast Guard identified the need for an improved system to prevent paint chip and spatter from entering the environment, and after considerable research it was decided to design and construct a steel pilot model Paint Float to provide a safe working platform to conduct topside maintenance. The original float measures 30 x 12 ft. (9 x 3.7 m), with draft of just 1.5 ft. (.5 m) and displacement of 32,000-lbs.

VT Halter Wins $16.3M Contract

VT Halter Marine Inc., signed a $16.3m contract to build a catamaran lift barge for Washington Group International (WGI) and WGI’s joint venture partner, Alberici Group. The vessel will be fitted with special lift equipment that will be used to transport and place precast concrete segments in the U.S. Army Corps of Engineers’ Olmsted Dam construction project. VT Halter Marine will build two 200 x 90 x 15-ft. units that will be assembled to form the catamaran lift barge. The vessel’s configuration will allow it to effectively assist in the Olmsted Dam construction efforts, which will take place near Olmsted, Illinois on the Ohio River. 2H 2006. The catamaran lift barge will be in service for approximately six years on this project. regard to structural hull design.

Coatings & Corrosion Control: Microbiologically Influenced Corrosion (MIC)

Recently, the use of certain environmental-friendly waxes or "semi-hard coatings", used by barge fabricators to protect the internal void walls and floors of marine double-hulled steel barges from corrosion, have fallen under scrutiny by some barge owners/operators. It is believed that certain paraffin wax coatings act as a food source for certain living corrosive microorganisms. These single-celled organisms are associated with a phenomenon known as Microbiologically Influenced Corrosion (MIC) that can cause localized pitting and eventually leaks in steel barge voids. This following examines the biological and chemical research that has recently been performed on the Jotun Paints, Inc, "beeswax" coating by two independent laboratories.

Feature: Leaving Home

For many years the fortunes of the Great Lakes-based shipbuilders and naval architects was based solidly on the building level of the owners who were also based on the 94,000 sq. mi. of water that makes up the five Great Lakes. That is no longer as true a statement as it once was. While there are many projects in this area designed and build by Great Lakes firms for owners in the area, an impressive number of significant commercial market projects as varied as Staten Island, New York ferries and Gulf of Mexico crew/supply boats were designed and or built on the Great Lakes. The Kennedy Class of double ended auto/passenger ferries is one of the most recognizable images of New York City. Every weeknight millions of people see one during the opening of the David Letterman Show.