Bollard Load Test System Ready to Launch

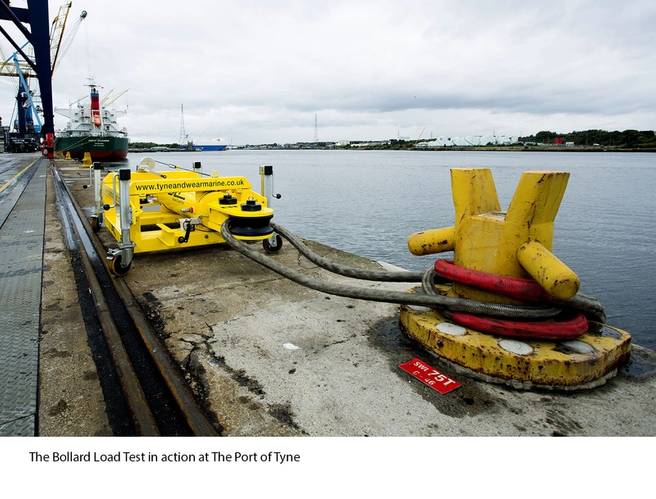

Working with the Manufacturing Advisory Service (MAS) and consultant Ade Walton from Prozeus, Tyne and Wear Marine (TWM) has spent the last year developing the Bollard Load Test (BLT), which uses a powerful hydraulic ram and specialist torque rope to recreate more than 100 metric tons of ‘pull’ when safely testing marine bollards.

This breakthrough replaces the traditional method of a tug pulling against the bollard, a method that has previously caused damage to vessels and can be dangerous to the people involved in the test.

The Port of Tyne initially approached the engineering team at TWM with the idea of finding an alternative and from a rough sketch the BLT was born.

The trademark has been registered and a patent is pending, with the long-term plan to roll out the testing service to other ports in the U.K. and across the world.

“I’m really excited about the Bollard Load Test and it appears I’m not the only one…we are about to start using the service at the Port of Tyne and four more ports are asking us to test their bollards for them,” explained Jeff Main, Managing Director at Tyne and Wear Marine. “Our designers and engineers have come up with a fully calibrated and easily deployable way of testing the strength of marine bollards, creating conditions equivalent to 100 metric tons with plans in place to increase this to 150 metric tons of pull in the next model.”

“With bollards requiring regular inspections, it should give us the perfect platform to create a specialist U.K. service division and, in order to get maximum exposure as quickly as we can, we are investigating the prospect of offering international licensing deals,” Main continued. “We are proud that this product has been designed and manufactured completely in the North East and this will be the case going forward. Two people have been directly employed so far and this will increase dramatically as we look to take turnover from £1.2 million to £4 million by 2018.”

Mike Nicholson, Harbor master at the Port of Tyne, added his support, “We have been extremely impressed with the results of the first successful trial and we are now ready to roll out a regular testing regime. We are confident that it will help guard against future bollard failures and provide greater safety and security for ships at our berths.”

The Manufacturing Advisory Service and Prozeus has worked with the company on the development of the BLT and in securing funding towards market research, IP protection and development of market entry strategies.

They will now focus on helping the firm seek legislation to certify the performance ratings of bollards, not to mention putting in place the foundations for the expansion of its service division and structure for potential licensing opportunities.

The service will involve ensuring each bollard is identified by GPS and has the potential to cut insurance premiums for ports all over the world.

Prozeus’ Ade Walton picked up the story: “Tyne and Wear Marine has successfully harnessed the considerable value of one of its many bespoke innovations. Working alongside MAS’ Alan Hewett, we have ensured the company has protected its IP for future use and have also looked at the best way to maximize the ‘breakthrough’ in terms of targeting potential ports and port maintenance companies who might operate the service as licensees.

“Between TWM, MAS and Prozeus, we hope to have put in place a world class global launch platform for the BLT.”

Due to the anticipated interest, Tyne and Wear Marine is currently in the early stages of building a new factory - adjacent to its current site - to give it more capacity and the ability to develop a bespoke production layout.

The company will again tap into support form MAS and Prozeus for tips on lean manufacturing and a complete feasibility study that it will use to leverage over £100,000 of funding from the GROW: Offshore Wind Flexible Enabling Fund.

MAS’ Alan Hewett concluded, “Tyne and Wear Marine is a great example of how a SME can take an exciting idea and turn it into a commercially viable solution for an established sector. We are now focused on helping the management team leverage future funding to create a world class production facility for the BLT.”

tyneandwearmarine.com

bollardloadtest.co.uk

mymas.org