New BWM Regs Cometh - Are you ready?

The global market for BWT systems is predicted to grow to over $34 billion through 2020 in response to IMO and USCG-based ballast water discharge regulations (Frost and Sullivan, 2012). BWT systems are now manufactured by dozens of companies around the world, including traditional suppliers of marine equipment, suppliers of municipal water and wastewater treatment equipment, and shipbuilders. As of November 2013, 35 BWT systems have received IMO-type approval from foreign administrations, and 28 of these have been accepted into the AMS program by the USCG.

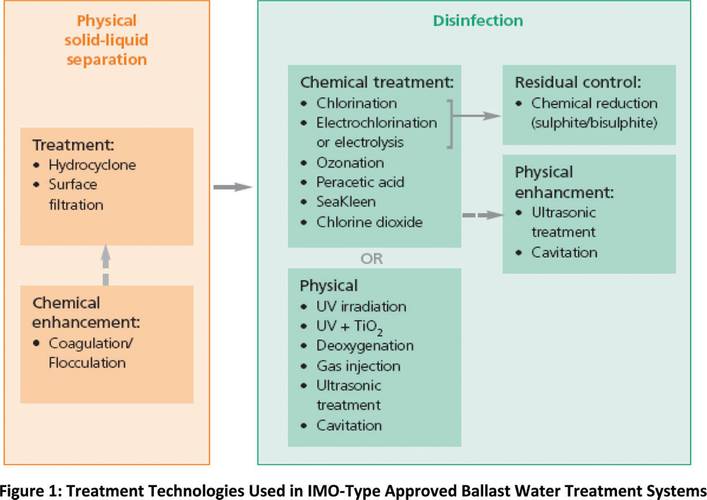

As shown in Figure 1, these systems include various treatment technologies and combinations but are typically arranged to provide two stages of treatment: (1) physical solid-liquid separation to reduce sediment and remove larger organisms, and (2) disinfection to kill or inactivate smaller organisms. The disinfection processes can be further classified into physical or chemical treatment processes. The latter may involve residual control to meet discharge limits for active chemical substances or physical enhancement technologies to improve treatment performance.

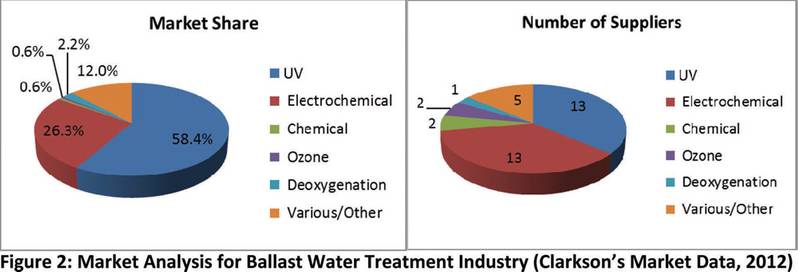

As shown in Figure 2, the global market for BWT systems is dominated by two treatment technologies - UV and electrochlorination. These are manufactured by 26 equipment suppliers and compose 85% of the approximately 1,500 IMO type-approved BWT systems installed to date. The basic process trains are generally described below:

UV Disinfection: This is a two-stage treatment process with a pressure-rated filter unit (typically with micron-rated disks or membrane elements) to remove sediment and larger organisms, followed by a UV disinfection unit to inactivate smaller plankton, bacteria and viruses. No chemicals are required to operate the system. During ballasting, water is typically processed through both the filter and UV stages as water is pumped into the ballast tanks. Solids captured by the filters are discharged at the ballasting location. During de-ballasting, the filter is typically bypassed and water is treated by the UV unit only before discharging overboard.

Electrochlorination: This is a two-stage treatment process with a micron-rated pressure filter or strainer followed by an electrochlorination unit. The latter is essentially an on-demand chemical system, which uses electrolytic cells to generate a sodium hypochlorite (bleach) solution from seawater and electricity. Some treatment systems pump the entire ballast water flow through the electrolytic cells, whereas others use a small slipstream to generate a concentrated hypochlorite solution, which is then recombined with the main flow. During ballasting, water is processed through both the filter and electrochlorination unit as water is pumped into the ballast tanks. A chlorine residual (or residual oxidant) is maintained in the tanks for a minimum contact time (typically a few days) to improve disinfection and eliminate regrowth of organisms during transit. During deballasting, a neutralization chemical (e.g., sodium bisulfite) is added to the water to remove the oxidant residual as it is pumped overboard. Note that this type of system cannot be used in freshwater areas such as the Great Lakes because it requires salinity for hypochlorite production.

Complying with the New Regulations

The new BWM regulation will increase costs for shipowners/operators to evaluate, install, operate (including additional record-keeping) and maintain BWT systems with regulatory compliance dates, starting now for new build vessels and at the next scheduled dry-dock for many existing vessels. They must therefore quickly become familiar with the new requirements, risks of non-compliance and necessary steps to bring individual ships or fleets into regulatory compliance.

For owners/operators of seagoing commercial vessels, most important will be to select an appropriate type-approved BWT system that is compatible with the ship’s existing ballast water system and can be operated to ensure compliance safely by the crew. Key design considerations for BWT system selection include:

• Ballast pump capacities and operating pressures,

• Ballast tankage volume (if required for disinfection contact time),

• Available space for the BWT equipment,

• Uptake and discharge piping arrangements,

• Chemical storage location (if required),

• Discharge sample location (for USCG inspection use),

• Ship routes (and associated ballast water quality conditions),

• Integration of the BWT system controls into the ship’s ballast control system,

• Training requirements for crew members.

BWT system selection is made more complicated in that the USCG has not type approved or certified any systems yet, although it plans to over the next year or two. In the meantime, AMS-accepted systems must be used with only a five-year regulatory compliance horizon, with no certainty that they will ultimately be approved by the USCG for long-term compliance with the BWM regulation.

Given the complexity and uncertainties of the BWM regulatory requirements, tight implementation schedule, system installation challenges, and the myriad of BWT systems on the market, many ship owners are hiring a qualified engineering firm to assist in selection of the most appropriate BWT system and work with the selected equipment supplier to design and install the BWT system on a particular ship or fleet. The planning, engineering and installation of the BWT system needs to be carefully coordinated with the vessel drydock projects.

The Authors

Christopher R. Schulz, P.E., is Senior Vice President at CDM Smith. Chris Schulz has over 30 years of experience in the planning and design of water treatment facilities in the United States and throughout the world. He served on the expert review panel for the USCG’s Shipboard Technology and Evaluation Program (STEP), which evaluated prototype ballast water treatment systems in shipboard environments. Randy Kullmann is Vice President at CDM Smith. Kullmann has over 27 years of experience in consulting, engineering, construction and operations. His experience spans all aspects of water treatment and he has been leading CDM Smith’s marine services, including compliance, information and safety management, as well as water treatment.

Excerpted from an article published in the Q4 edition of Maritime Professional

(As published in the February 2014 edition of Maritime Reporter & Engineering News - www.marinelink.com)