Metrol Boosts Efficiency with Miko Magnets

Metrol Technology disclosed that it developed a subsea tool from the technology of Miko pipe magnets. The company said it is currently gaining cost and time benefits through having perfected the use of powerful permanent magnets when positioning instrumentation on seabed structures.

Most Metrol products are the result of advanced research and innovative technology but it only took some alert lateral thinking to realize that the powerful magnets manufactured in Norway by Miko AS can eliminate the need for costly installation with the underwater welding of instrument brackets, clamps and containers. Because of this the magnets are now in regular use by Metrol on projects in the North Sea and in Atlantic waters.

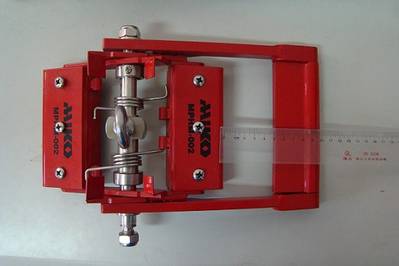

The Miko pipe magnet that was chosen for this task features two powerful magnetic pads hinged across a central axis. The magnets are free to move and will adhere to the surface of steel pipes of any diameter between eight and 42-inches. A stainless steel eye enables a cable to be attached when the magnet is being used for its intended purpose of lifting pipes. However, when one is being used by Metrol the eye can be used to hold an instrumentation receptacle. That may then be attached to almost any of the varied shapes encountered on seabed structures.

Because each magnet is capable of holding up to 200 kg of valuable instruments the devices deployed by Metrol face no danger of being moved or lost. Yet despite the powerful holding capabilities of the magnets, an integral lever enables the adhesion to be broken easily by a diver or ROV so that the instrument can be easily recovered or relocated with the magnet.

Ben Taylor, global projects manager with Metrol, explained that once they had double-checked the half-life and corrosion resistance of high performance neodymium magnets they were able to trust them with their valuable instrumentation. “We have found that they provide versatility especially when fitting equipment in confined spaces. Most importantly they reduce design and engineering time. We developed some ROV-friendly shackles for the magnets and now they eliminate the need for welding. This saves engineering design time, money and in some cases it can mean the difference between a job happening or not.”

Miko said its expertise in magnetic products also extends to its range of salvage patches. These are widely used by emergency services and aboard naval vessels where they can provide an almost instant water-tight seal for damaged ships or leaking storage containers. The company’s expertise also enables it to provide customers with practical advice on the transport and use of powerful magnets and to devise ways in which they can be used to solve other difficult fastening problems.

www.miko.no