3D Machining Puts Wind in the Sails

With ESPRIT CAM software, Armor Mécanique has the wind in its sails; 50% time savings, better quality and new markets thanks to 3D machining

Established in 1984 as a company dedicated to engineering marine motors, Armor Mécanique is situated in the port of Lorient. And while the coastal view remained picturesque, the ensuing years brought change. The company, founded by Marcel Février, is now dedicated to precision engineering and boilermaking. In 2005, upon Février’s retirement, experienced precision engineer Franck Vincent took on management of the company. Upon taking up the reins of Armor Mécanique, Vincent found that he had quite a lot on his plate.

Keeping Up with the Times

For starters, Vincent found that factory conditions were, in many ways, more evocative of the industrial revolution than the modern technological era. The workshop was dirty, the machines scattered about with no sense of logical organization. He buckled down and conducted a complete reorganization of the workshop, including the installation of cranes and high-performance computer-aided-manufacturing (CAM) software. His strategy was to radically improve the company's productivity.

In 2012, 80 percent of the machine pool was renewed and now comprises three machining centers — or sophisticated CNC machines that can perform milling, drilling, tapping and boring operations at the same location with a variety of tools, including one milling machine, four two-axis lathes and one teach-in lathe. A technician first and foremost, the manager reconfigured the workshop into technological sectors with the aid of Jean-Pierre Olmeda, a machinist with the company since 2000, whom he appointed workshop manager.

ESPRIT CAM for Complex Geometry

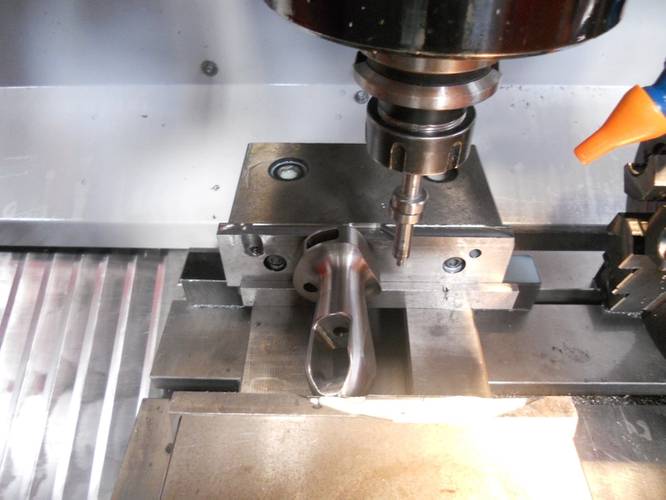

In line with its overhaul of operations, the company adopted a proactive approach and canvasses for new clients in the region. It targets small production runs of one to 100 parts. In the past, Armor Mécanique produced only simple mechanical parts in 2D, but has evolved to meet the changing needs of clients who demand the machining of more complex shapes. To accomplish this, Olmeda uses the company’s machining center and ESPRIT CAM software by DP Technology Corp. to generate the machining paths for the manufactured parts, including esthetic boat deck fittings, miscellaneous boat deck accessories (cleats, bowsprits, etc.) and racing vessels. Machined from solid block, these parts must not have any jagged edges.

Priority Goes to Quality and Reliability

"The sailboat racing activity is irregular," Vincent explained, "since it depends on the races, and this is difficult to manage. The work is always rush jobs, and we need to produce high-end, extremely technical parts. We've become the specialist in manufacturing highly individualized items. For competition, what counts is the quality and reliability of the parts; the cost is only a secondary consideration." Armor Mécanique produces deck fittings for Karver System and for prestigious sailing craft, including the Virbac-Paprec 3, multiple winner of the Jacques Vabre Transatlantic Race and the Barcelona World Race, Banque Populaire, Groupama, etc.

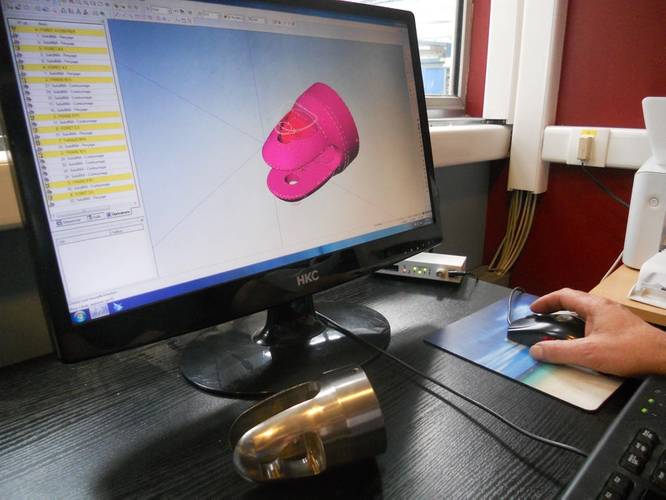

To program the machine tools, ESPRIT for two- and three-axis milling, as well as two-axis turning, is installed on a computer available to everyone in the shop. With his know-how in both milling and turning, Olmeda uses the 3D, four-axis software for complex parts. At Armor Mécanique, the operators are genuine craftspeople. Their know-how enables them to decide how to make a part, inspect it and guarantee that it fulfills its purpose, the objective being to produce the entire part according to spec at the first attempt.

All the machining centers are programmed using ESPRIT. Olmeda explained, "I was tired of seeing the operators spending entire days entering programs via the machine keypad, in particular for turning recurrent parts. The use of ESPRIT has brought us 50 percent time savings, improved machining quality and access to other markets, thanks to the 3D."

A Software Application and Services

Armor Mécanique receives the plans for the finished parts in IGES or DWG format and uses the Alibre CAD software for producing the layout. "It's easy for us to recover the file in ESPRIT," Olmeda said. "The machining method for the part is defined at the same time as the programming. The software is very rapid, easy to use and, following the training, the implementation of the 3D module is simplicity itself. We also appreciate the quality of the post processors and the services provided by NC Prog, distributor for DP Technology. We can contact them at any time, and they can take control remotely on the PC if required. When a new software version comes out, they come and install it on our PC, train the users and answer all our questions. It's a genuine partnership relationship."

Today, Armor Mécanique has 19 employees and revenues of €1.8 million (about $2.4 million USD), and serves customers from multiple industries. The majority of these customers work in industry and equipment manufacturing. The sectors of activity of its other clients include sailing, special machinery, chemistry, pharmaceuticals, automotive equipment and the oil sector. Its customer portfolio includes SNRI (industrial valves), the Bolloré Group (energy, automotive), the Guerbet Group (pharmaceuticals), GEA BTT (oil, gas and chemicals industries), and Avon Automotive (tools). For these customers, Armor Mécanique produces high-precision parts, from the simplest to the most complex, machined from all types of materials.

In the months to come, Vincent will continue with the renovation of the building, the implementation of a production management system and the renewal of the machine pool. The idea is not to make a clean technological break but to keep improving, both in terms of equipment and know-how. He envisions hiring a new operator, as well as acquiring a new lathe, a two-axis machining center and a new ESPRIT license. For Armor Mécanique, the objective is to remain ahead of the field.

About the Authors

Veronique Albet is manager at Comcordance (Macon, France); and Hélène Horent is marketing assistant at DP Technology Europe (Montpellier, France)