Cracked Muffler Led to Towboat Fire -NTSB

Cracks in a muffler and the substantial use of combustible materials in accommodation spaces led to a fire aboard a towing vessel last year on the Gulf Intracoastal Waterway near Freeport, Texas, the National Transportation Safety Board (NTSB) said Thursday.On June 25, 2022, the four-person crew aboard the towing vessel Mary Dupre departed Port Comfort, Texas, for Houston, pushing a single barge loaded with bio-diesel fuel. The following day, a fire broke out, leading to a total loss of the vessel, which was estimated at $1 million.

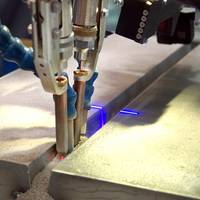

Pemamek Develops New Semi-narrow Groove Welding Solution

Pemamek LLC, a North American subsidiary of Finland-based Pemamek Ltd., has developed an automated semi-narrow groove welding solution with proven success in welding exceptionally thick plates ranging in size from 2 inches to 6.5 inches. Called Semi-Narrow Gap Welding, this SAW process uses significantly less consumables over the length of the operation resulting in a strong bond in less time and with fewer costs.Based on submerged arc welding (SAW), the LSO process employs a welding head equipped with 5/32-inch wires.

ESAB Innovation Aims to Make Shipyard Welding More Efficient, Accurate

Jeff Chittim, ESAB’s North American Senior Product Manager for Heavy Industrial Products, discusses how WeldCloud online applications and the ESAB Heavy Industrial Product Line are a powerful tandem to help shipyards improve weld quality and efficiency.While automation has gone a long way in making shipyards more efficient, today shipbuilding remains a hands-on endeavor, with a dearth of ‘welders and fitters’ being a common lament.Technology companies such as ESAB, a global supplier of welding and cutting solutions across industries…

Mooring Equipment Failure Led to Barge Grounding in Alaska -NTSB

A fatigue crack ultimately led to a fishing tender barge breaking loose from its mooring buoy and grounding during a storm near Ekuk, Alaska, the National Transportation Safety Board (NTSB) said in a recent marine investigation report.On August 30, 2020, the fishing tender barge SM-3 broke free from the buoy it was anchored to and began drifting. The six-person crew deployed two emergency anchors, but the barge continued to drift and grounded on the beach. No injuries were reported. There was a 3-mile debris field on the beach.

PHOTO & VIDEO: Johan Castberg FPSO Sets Off for Norway

Singapore's Sembcorp Marine has delivered the Norwegian Barents Sea-bound Johan Castberg FPSO to Equinor. The FPSO has set off for Norway, loaded aboard Boskalis' Boka Vanguard semi-submersible heavy transportation vessel.Johan Castberg is Sembcorp Marine’s first EPC newbuild FPSO. Sembcorp Marine’s scope of work for the Johan Castberg FPSO vessel comprised the construction of the hull and living quarters.Upon final completion in Norway, the FPSO is scheduled for deployment at the Johan Castberg field in the Barents Sea, about 240km from Hammerfest, Norway.

Tech File: Automated Welding Solutions

Pemamek has provided automated welding solutions to the shipbuilding industry for more than 25 years. Modular lines consisting of everything from simple robotic welding systems to entirely integrated plate preparation, joining and finishing operations can be built according to customer needs. But, according to Michael Bell, Sales Director for Pemamek LLC, the North American subsidiary of Finland-based Pemamek Oy, their systems are customizable for all types of vessels ranging from sub birthing barges…

Equinor: Several Factors Behind Faulty Welds on Johan Castberg FPSO Hull

Norwegian oil and gas giant Equinor last year said that the delivery of an FPSO, being built for the Johan Castberg field development in the Barents Sea, would be delayed after the company discovered issues with the weld quality of the hull of the FPSO under construction in Singapore.In an update on Monday, Equinor said that, following the initial findings, an in-house investigation team from Equinor had studied the deviation in quality of welding and inspection of the Johan Castberg FPSO…

Seaspan Cavalier Repower: Long Life, Big Hours

“We got 59,115 hours on those engines, without ever removing a head,” says Seaspan International’s Port Engineer Kevin Tweedy, “And they were still running. So, at 5,000 to 5,500 hours per year, we could easily have done 60,000 hours.”But the company schedule worked to do a like-for-like repower. The pair of 850-horsepower Tier 1 Cummins KTA38 diesels were pulled out, and a brand-new set of 850-horsepower Tier 2 KTA38s went in.The Seaspan Cavalier was built in 1974, along with three sister ships.

Cutting Machinery Firm HGG Eyes US Growth

With much of North America still reeling from the pandemic, HGG Profiling Equipment continues to grow, responding to immediate and anticipated customer demand for profile-cutting machinery. Since opening its new 6,500-square-foot facility in Houston in this spring 2020, HGG has added an area manager to its sales and support team, three new customer service and support specialists, and two new service technicians.HGG recently expanded its North American sales coverage by adding Todd Wellens as Area Manager for eastern and midwestern US and Canada…

Equinor's Johan Castberg FPSO Faces Delays as "Weld and Fatigue-analysis Errors" Found

Delivery of the FPSO destined for Equinor's Johan Castberg field in the Barents Sea is expected to be delayed after the company found issues with the weld quality and fatigue calculations program.The FPSO hull was ordered by Equinor (then known as Statoil) back in 2017 from Singapore's Sembcorp Marine and it was at the time said that the construction of the hull was "the most time-critical delivery for the completion of the Johan Castberg project," first production from which…

Scrubber Corrosion: Addressing the Issues

A focused Q&A with M.Sc. Chem. Eng. Anders M. Sørheim, Yara Marine TechnologiesHow important is material quality when selecting a scrubber system?If the intention of a scrubber installation is to operate the scrubber for the lifetime of the vessel, assuming a minimum of 10 years, then the material quality is imperative. A study performed by the American stainless-steel manufacturer ATI titled “Evaluation of Alloys for Marine Exhaust Scrubbers – Effect of Welding and a Crevice” confirmed the importance of correct material choice for scrubbers.

RINA Classes Prysmian Cable Layer

The recently named cable laying vessel Leonardo Da Vinci, set to join the fleet of energy and telecom cable systems company Prysmian Group in the second quarter of 2021, incorporates innovative features that required the new battery power class notation to be developed by classification society RINA.The new vessel is being built by Vard, a Fincantieri company, at one of its shipyards in Norway, with the hull being fabricated at Vard Tulcea in Romania. RINA has carried out a full…

New Nippon Paint Targets Chem, Product Carriers

Nippon Paint Marine has added to its NOA range of self-indicating epoxy coatings with a new system specially developed to protect chemical and product carrier tanks from corrosion and cargo contamination.NOA PC 700, a phenolic/novolac-based epoxy, is resistant to a wide range of chemicals, solvents and petroleum products, including those containing xylenes, methyl ethyl ketone, methanol, caustic soda and LSA fuel oil.Makoto Nakagawa, General Manager Sales and Marketing, Nippon Paint Marine Coatings…

Vigor Lays Keel for Next Gen Landing Craft

Representatives from the U.S. Army and federal and local elected officials joined Vigor for a keel laying ceremony, celebrating the first milestone in the construction of the Army’s next generation landing craft, the Maneuver Support Vessel (Light) or MSV(L).The nearly billion dollar contract to build MSV(L) was awarded to Vigor in October, 2017. The new design, developed in partnership with BMT, improves the capabilities of the current LCM-8 and provides the optimal combination of performance…

Lowering Shipbuilding Costs with Immersive Training

The fiercely competitive domestic boatbuilding industry looks for any advantage in the day-to-day battle for bottom line efficiencies. ‘XR Technologies’ offer an edge to shipyards as they grow their workforce.In the shipyard, skills such as welding and coating are in high demand. The ability to lay down a proper bead, or perfect the mil build on a ship’s hull can make the difference between a successful project and a failed inspection. XR technologies are valuable compliments to traditional training programs (XR is an umbrella category for virtual reality [VR]…

SeaCrest Builds for Domestic & Foreign Buyers

Seacrest’s Managing Director Tavipol Hemangkorn receives guest in a board room decorated with models of large crew boats, ASD tugs and a range of other vessels that his firm has built. Located just outside the mouth of the Chaophraya River at Samutprakarn, Thailand the yard’s three marine ways can launch vessels directly into the deeper waters of the Gulf of Thailand. They can accommodate vessels up to a 22-meter beam and up to 2500 metric tons. Outside the company offices an…

Advanced Coatings Enhance Aesthetics, Durability and Safety

As Maritime Partners LLC built out its modern fleet of new tank barges, quality coatings and responsiveness to last-minute color changes supported that fleet expansion. Sherwin-Williams was there to meet the challenge.The hulking silhouette of a tank barge is instantly recognizable to anyone who has spent time on the shores of an inland waterway in the United States. These massive flat-bottomed vessels help to maintain the healthy functioning of the domestic economy, transporting vital commodities such as agricultural products, chemicals and petroleum products.

Water Backed Welding & Fixing FPSOs

Although MTL has a robust oil and gas heritage, with formidable experience in the global energy marketplace, it also invests heavily in R&D and undertake rigorous testing and research from its base in Kintore, Aberdeenshire. MTL recognizes the importance of progression and continual improvement for the benefit of the organisation and its staff. As a young engineer I’ve been afforded the opportunity to see new ways of working develop from the spark of a good idea through rigorous testing and finally to its successful deployment in the field.

NASA Welding Technologies Could Revolutionize Workboat Fabrication

Solid-State Welding Processes Being Developed for NASA Manufacturing Programs Could Significantly Reduce Workboat Fabrication CostsWhether it is for a tug boat, cargo vessel, or an offshore supply ship, much of the workboat fabrication industry is located along the Southern Coast of the U.S. But a visit to any one of the workboat facilities in that area (or any other in the country) would reveal antiquated and archaic fabrication processes used seventy years ago. The workboat manufacturing process is very expensive, labor intensive, and has not really changed since World War II.

Subsea Robotics for Renewables

As the global fleet of offshore renewables fleet increases, ways to reduce the cost and increase the efficiency and safety of operations and maintenance work, using robotics and autonomous systems, will also grow. Elaine Maslin reports.Robotics and autonomous systems are moving into many areas of modern day life. It’s becoming harder to avoid them, from our phones to automotive systems and now offshore energy renewable projects.Both are seen as tools to do otherwise dull, dirty or dangerous work…

Learn to Weld with a Virtual Personal Trainer

The Fohnsdorf Training Center is located in Styria, Austria. To train welders, it uses a virtual welding system – the Virtual Welding simulator from Fronius, the Austrian technology leader. The simulator employs a virtual trainer to provide 1:1 training for the center’s students, an approach that has a positive impact on training quality.A young student carefully guides the welding torch. The weaving motions she makes as she welds the single-V butt weld in front of her appear very composed, an impression that is confirmed by the consistently positive feedback from her trainer.

'Best of the Best' Welds Help Metal Shark Succeed, Expand

Louisiana-based shipbuilder eliminates preheat and saves time with Dynasty 400 TIG welders.As a well-known shipbuilder specializing in the design and production of vessels, Metal Shark Boats doesn’t shy away from tackling tough and diverse jobs. It’s a philosophy that has fueled the company’s growth from small shop to major industry player.Launched more than three decades ago as a small family-owned operation crafting custom fishing boats, the transition to Metal Shark Boats began…

Barge Company Fined for Fertilizer Spill into Columbia, Snake Rivers

A local barge company has been fined $18,000 for spilling 40,000 gallons of liquid urea ammonium nitrate into the Snake and Columbia rivers. Urea ammonium nitrate is a common fertilizer that is corrosive to steel. An investigation by the Washington Department of Ecology found that two steel tank barges owned and operated by Tidewater Barge Lines, Inc. were not properly maintained, causing the liquid fertilizer to spill into the rivers during three separate incidents in April 2017. The first spill occurred between April 11 and 21 during transfer and storing operations at the Tidewater Snake River Terminal in Pasco. Investigators determined that 16,639 gallons of urea ammonium nitrate were released by Barge No. 78 due to corrosion of the storage tank.