Dynaligner Aims to Eliminate Shaft Misalignment

More than 20 percent of all machinery claims, as well as catastrophic failure, off-hire and repair costs are caused by misalignment – the cause of almost all propulsion train damages Sweden’s Dynaligner AB said, adding that the problem is getting worse as modern ship design pushes the envelope.

However, a Swedish and Dutch invention aims to eliminate misalignment, modernizing today’s shaft alignment practice. The device, the Dynaligner, is said to offer troublefree operation of marine propulsion trains, irrespective of ship operation condition or hull deflections, etc. Dynaligner ‘s developer said the propeller shafting is correctly aligned at all times during ship operation to avoid any mechanical behavior causing inappropriate bearing loads and wear/vibrations. The patented invention particularly focuses on, protecting the engine/gear, intermediate bearings and the sterntube bearings.

Analytical Problems

Discussions on the analytical problems with propeller shaft alignment have been going on for decades. Still, the same mathematical models remain in use. It has been obvious that the general and uncritical use of the single-support-point bearing model is one of the main reasons for the poor analyses. This simplified model is inappropriate for analysis of operation conditions as bearing length and clearance are omitted. Only concentrated bearing loads can be considered. It is not possible to analyze how the lubrication oil film acts on the pressure distribution in operation condition. The dilemma is traditionally evaded by assuming even distribution. The concentrated bearing load is simply divided by the supporting area to obtain the pressure, indeed a very hazardous procedure.

Sustainable and effective solution

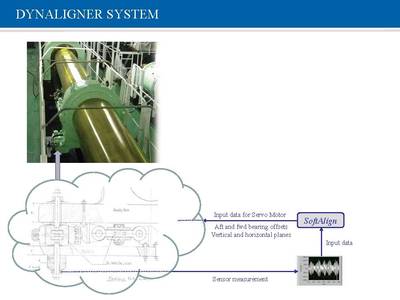

Another deficiency of the simplified model is its inability to reveal load peaks in the bearing edges in operation condition. Such load peaks are quite common. They are often counter-directed, which means that an unloaded zone occurs in between. Unloaded zones may cause problems. They are typical vibration sources. Nevertheless, using traditional shaft alignment methods is a well-established practice in the shipbuilding industry, including class societies. With the modern technology of today it is high time for a modernization. An update with Dynaligners and the multi support point bearing model will open a new chapter in shipping and ship’s shaft alignment. The Dynaligner consolidates sustainable and effective solutions of the problems of ship’s shaft alignment. It replaces the traditional one-off procedure of manual shaft alignment at the shipyards. Instead, continuous and automatic adjustment of the bearings are performed during ship operation. The ingenious core of the whole invention is how to keep the bearing house solid to the foundation structure during adjustments. Controlling software is included.

Totally eliminating misalignment

The Dynaligner solution aims to totally eliminate misalignment during ship operation. All problems related to misalignment will become history for the ship owning industry that until now has been helpless in the face of misalignment. A satisfactory operating alignment will become something to take for granted. The Dynaligner is the only alternative that meets the objective. It will solve all problems and overcome all deficiencies mentioned above. The installation can be carried out on newbuilds as well as on existing vessels in service when the vessel is in dock for propeller shaft survey.

For the shipowner, the most important economic advantage of using Dynaligners is saving all the costs brought about by misalignment, not least the class-required regular stops for tailshaft survey in dock. There are no delays during the new build phase due to shaft alignment procedure. The troublesome jack and sag&gap methods are not needed anymore. The propeller shafting can be installed before the superstructure is mounted on the hull, which will save a lot of time. It’s a solution that makes sense: disengaging the propeller shaft bearings from the ship foundation and hull deflections. Dynaligner and the controlling software Softalign could well be the innovation that changes shipping.

About the inventors

Based in Sweden, Anders Rubin from Propulsion Software AB is a consultant in vibration and alignment of ship’s propulsion machinery. He has an MSc from the Royal Institute of Technology, Stockholm, Sweden. In The Netherlands, Willy Rantanen of De Fin - Offshore & Hydraulics is a consultant in hydraulics in the offshore and shipping industry. He has a DSc in applied physics.