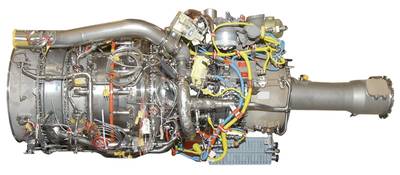

GE: Significant Progress in GE38 Engine Testing

GE reports significant progress in the GE38 engine qualification program at its Lynn, Massachusetts, test facility. Testing to date indicates the GE38’s capabilities will successfully meet United States Navy requirements for the Ship-to-Shore (SSC) project at an affordable cost.

Nearly 1,000 hours have been completed during GE38 factory engine testing under the U.S. Navy’s Heavy Lift Replacement System Development and Demonstration program. The first of 20 flight test engines -- shipped in August 2011 -- will be installed on the first CH-53K ground test prototype helicopter. This is the latest variant in Sikorsky Aircraft Corporation’s CH-53 series, being developed for the U.S. Marine Corps heavy-lift mission. In addition to the operation of these 20 flight engines, the GE38 testing program includes five factory-test engines that will accumulate more than 5,000 engine test hours by 2013. “The recently completed 300-hour durability test has validated the GE38’s engine performance and hot section durability,” said Brien Bolsinger, GE Marine general manager. GE Marine is part of GE Aviation, Evendale, Ohio.

In addition, high pressure turbine aeromechanics, heat transfer survey tests, lube system qualification testing and sea level performance assessments demonstrated the GE38 engine’s robust design and its ability to meet the mission requirements of the SSC. “The GE38 was competitively selected in 2006 for the U.S. Navy/Marine Corps CH-53K helicopter program, versus the P&W150 and Rolls Royce AE1107 aircraft engine -- parent of the MT7,” said Bolsinger. “The GE38 is ideally-suited for the SSC, electrical generation for DDG 51-class destroyers and other future surface combatants.”

The GE38 architecture includes state-of-the-art aerodynamic features, plus improved cooling schemes and materials for added durability. The engine provides 15% lower fuel consumption than required by SSC specification, delivering energy savings as well as longer range and/or more payload capacity compared to other engines in its class. The GE38 power margin provides mission flexibility and enhanced performance, while the engine’s simplified design translates to improved reliability and lower operating and support costs. The GE38 features a more rugged compressor design to increase durability and resistance to sand erosion and salt water corrosion -- ideal characteristics to withstand the SSC’s tough operating environment. Further testing during 2011 includes a series of ingestion tests, plus high cycle fatigue testing to validate the engine’s capability to operate in severe environments.

“The GE38 engine is designed to be the most technologically advanced turboshaft engine in its class. GE Marine’s strong commitment to technology investment and dedication to understanding customer requirements has resulted in an engine with superior benefits for the SSC. The engine not only meets the demanding SSC profile but it also has growth power capability to meet future mission requirements,” Bolsinger added.