Power Below the Waves: ABB Subsea Transformers

ABB has delivered subsea transformers for fields in the North & Norwegian seas & the Gulf of Mexico for operation at depths of up to 2,000 m.

Subsea transformers are an ABB innovation. Deployed in extreme conditions in ultra-deepwater, these high-tech workhorses provide the power for heavy-duty equipment on the sea floor - enabling declining oil and gas fields to be more productive and making new deepwater fields accessible.

ABB delivered the world’s first commercial subsea transformers in 1998 – a pioneering achievement that helped take subsea oil and gas extraction into a new and more productive dimension.

These robust, maintenance-free and exceptionally reliable transformers are used to power the field equipment on the seabed – boosters, pumps, compressors, pipeline heating systems, frequency converters and wave hubs.

They operate in some of the most extreme environments imaginable for transformers – at depths of several thousand meters and at distances of 50 to 100 km from the nearest platform or shore. The performance levels required of deep-sea equipment are very high, and reliability is decisive.

Designed for endurance

ABB subsea transformers are designed to operate in these demanding conditions of great depth and extreme atmospheric pressure. They are liquid-filled and pressure-compensated to keep the internal pressure close to that of the outside water by immersing the internals in liquid and eliminating all air- and gas-filled voids.

Since transformers get hot when they run, the type of liquid used inside the transformer is critical to its successful operation. ABB uses high-quality insulating oil with a low expansion coefficient and high compatibility with the other materials and components in the transformer. Because the transformer is housed in a solid tank that cannot expand, even when hot, the oil is degassed before installation and the tank is provided with a pressure compensating system.

High-grade steel is used for the casing to cope with the high pressure of deep-sea locations and to protect the transformer from the corrosive effects of seawater and colonization by living organisms.

Once installed on the seabed, no maintenance is required. Since the scope for repairs is limited, due to the expense of raising equipment to the surface, ABB has invested a great deal of resources to ensure that all components are of the highest quality and are rigorously tested to ensure a long maintenance-free operating life.

This stringent approach has ensured that all 20 ABB subsea transformers currently installed are operating reliably and safely and are providing exceptional performance and cost benefits for their owners.

Installations

ABB has delivered subsea transformers for fields in the North and Norwegian seas and the Gulf of Mexico for operation at depths of up to 2,000 m.

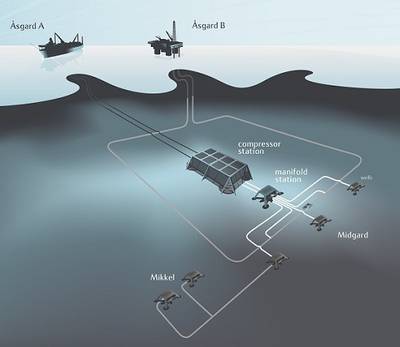

Later this year ABB will deliver nine subsea transformers for the world’s first subsea gas compressor station at the Åsgard oil and gas field in the Norwegian Sea. Although they will operate at a depth of 400 m, they are capable of operating in the deepest fields on the planet - 3,000 m below the surface.

Subsea Deepwater Transformer: Image credit ABB