Polymeric composites and coatings transform heavily corroded rudders

In the Marine industry, cavitation commonly occurs on hydrofoils, rudders, stabilizers, as well as on propulsion systems. Cavitation damage can lead to severe erosion problems and render equipment useless if left untreated. Millions are spent every year on replacing equipment damaged by cavitation. This is not only expensive and time consuming, but the like for like replacement solution will not solve the problem. Repair methods involving welding will not stop the problem from reoccurring either, and the heat introduced can cause HAZ (Heat Affected Zones) and stress corrosion cracking. As a result, a repair and protection alternative able to withstand the cavitation forces for the long term is required.

Suffering with erosion and corrosion pitting damage, the rudders on a vessel at a U.S. navy base in Japan were in urgent need of a long-term, cavitation-resistant solution. While extensive maintenance work was needed, totaling a surface area of 58m², the navy base required the application to be carried out with as minimal downtime as possible, so as not to impede on the vessels operations.

System Selection: Flexible and Durable Materials

Due to its simple and quick application procedure, the navy base decided to repair and protect the damaged rudders with a combination of cold-curing Belzona polymeric systems. Following inspection by Belzona representatives, Belzona Technical Services Engineer, Yusuke Nishi said, “It was decided that the pitted areas should be rebuilt using Belzona 1311 (Ceramic R-Metal). This ceramic filled, epoxy-based composite will provide the level of strength and durability necessary to ensure the substrate will remain robust, even when subjected to the aggressive marine conditions. To encapsulate this, a corrosion-resistant coating, Belzona 1341 (Supermetalglide) was chosen. Finally, two coats of Belzona 2141 (ACR-Fluid Elastomer) were further specified. The flexible yet robust properties of this elastomeric system will enable the rudders to resist cavitation, even at ultra-high velocities, successfully fortifying the vessel for the long term.”

Fast and Simple Application Procedure

- Firstly, the rudders were sprayed using a high pressure (41.4 - 68.9 MPa/ 6,000 -10,000psi) water jet to remove all loose rust and chlorides. The substrate was then tested using an Elcometer 134S (Chloride Ion Test Kit) to ensure the chloride content was less than 20mg/m².

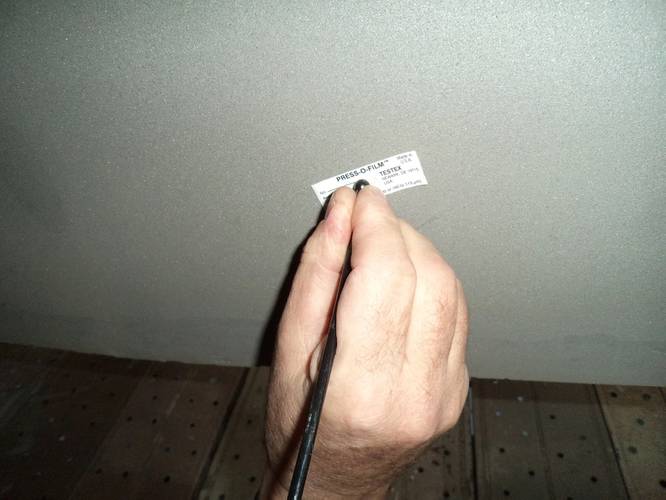

- The substrate was then grit blasted to give Swedish Standard Sa2 ½ (near white metal finish), ensuring a 75-125 µm (3-5 mil) profile was achieved. Using Testex replica tape, the surface profile was measured to ensure the correct surface profile was achieved.

- Belzona 1311 was then used to rebuild the pitted areas back to the original dimension of the rudder, taking care to fill in the pits correctly and to leave a smooth surface free of ridges.

- Next, Belzona 1341 was applied on all cavitation damaged areas with a single 250µm (10mil) coat. After eight hours, once the coating was firm and dry, the area was over coated with Belzona 2941 (SP Conditioner). To ensure this was applied as thinly as possible, a brush with bristles 12mm long was used.

- Finally, Belzona 2141 was applied in two coats (black on green). This flexible elastomeric system was applied to the substrate with a thickness of 500-750µm (20-30mil) per coat.

Inspection After Two Years Confirms Durability of Belzona Coating

The application was inspected after two years in service and was mostly found to be in perfect condition, with only minor mechanical damage in localized areas. The chosen repair and protection system had overcome the major cavitation and erosion problems, successfully protecting the asset for the long term. The application itself required only five days to complete, with just ten and a half hours of manual labor, and did not require hot work as the complete Belzona system is cold applied. This facilitated a quick repair ensuring minimal downtime was incurred.