Marine News' Top Vessels of 2023

The November edition of Marine News magazine highlighted a selection of the most notable American newbuilds delivered of 2023—from a first-of-its-kind green towboat, to the lead vessel in a series of game-changing ships to train U.S. mariners.Empire StateAs the lead vessel in a series of five new training ships being constructed to serve America's state maritime academies, Empire State is easily one of the most important U.S.-built vessels delivered in recent memory.Built by Philly Shipyard for the U.S.

Kirby Christens the US' First Plug-in Hybrid Electric Inland Towboat

The United States' first plug-in hybrid electric inland towing vessel was christened at a ceremony in Houston on Friday as the commercial marine industry continues to implement new technologies to reduce its environmental footprint.Kirby Inland Marine's Green Diamond will be time chartered by Shell Trading (US) Company, which will use the vessel to push barges throughout the Houston port region. According to Kirby, the vessel can achieve an estimated 80% reduction in fuel use and related emissions.“We are excited to be the first to market with a plug-in hybrid inland towing vessel…

Naval Shipyards Recruiting Robots

Inspecting fuel and ballast tanks. Sand-blasting old paint coatings and applying new ones. Removing corrosion on ships, submarines, aircraft and other vehicles.These are some of the unpleasant jobs in naval shipyards and maintenance facilities that could be made safer by pairing human workers with robots. Experts say this could improve the speed and efficiency with which the U.S. Navy sustains its assets—and expand the career paths of current workers (and create new jobs) by teaching them to operate…

Wilhelmsen Delivers 3D Printed Parts to Berge Bulk

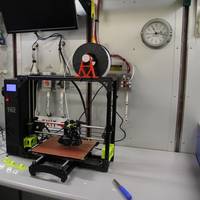

Norway-based global maritime industry group Wilh. Wilhelmsen Holding ASA announced that Berge Mafadi, a Berge Bulk vessel has received the world’s first commercial delivery of 3d printed scupper plugs, as part of Wilhelmsen’s Early Adopter Program.According to a press release, the program, where customers have exclusive access to on-demand additive manufacturing was launched by Wilhelmsen’s Marine Products division in December 2019. Customers include Berge Bulk, Carnival Maritime, Thome Ship Management, OSM Maritime Group, Executive Ship Management and Wilhelmsen Ship Management.“We are very excited with this milestone - completing one of the first commercial deliveries of 3D printed parts in the maritime industry…

World First: Printed Hollow Prop Blade

French defense contractor Naval Group and French elite engineering school Centrale Nantes have printed the first demonstrator of hollow propeller blades by metal additive manufacturing as part of the European H2020 project, RAMSSES.Naval Group, formerly known as DCNS, said that this collaborative program, funded by the European Commission, aims to reduce the environmental impact of ships.Centrale Nantes and Naval Group are taking the lead within this project on the production of innovative propeller demonstrators to improve the operational capabilities of ships.In order to improve vessel propulsion, Centrale Nantes and Naval Group are using additive manufacturing to design large parts (propellers of 6m in diameter)…

India's CEMS Establishes 24 labs for Skill Development in Maritime

The Centre of Excellence in Maritime & Shipbuilding (CEMS) in India, a well-funded start-up in skill development for maritime and shipbuilding sector, has announced setting up of 24 labs -6 in Mumbai and 18 in Vizag campus. It also shared the list of courses being offered. The labs being set up include Product Design & Validation, Advance Manufacturing, Hull Design, Automation, Welding Technology, Robotics, Virtual Reality, Advance Machine & Robotics, Electrical and several others. The announcement was made in the first seminar on Competencies, Employability, Methodology and Skills organized by CEMS in Mumbai. Arun Sharma, Executive Chairman said: “CEMS has established one of the first of its kind of infrastructure in Asia Pacific with 24 labs.

BAE Systems, Flinders University to Train Shipbuilding Workforce

A new agreement between BAE Systems Australia and Flinders University will see students and industry working together to develop new ways to provide Australia’s defence force with the evolving capability it needs and train the shipbuilding workforce of the future. BAE Systems is one of three companies bidding to build nine Anti-Submarine Warships for the Royal Australian Navy. The company is proposing an Australian variant of the Global Combat Ship currently being manufactured in the UK for the Royal Navy. Flinders University will receive access to BAE Systems’ digital shipbuilding tools, processes and methodologies and turn these into development programs to train the people who will build the Future Frigates and integrate the ships’ complex operating systems…

Huntington Ingalls Enters Partnership for 3D Printing

Huntington Ingalls Industries announced it has partnered with a company specializing in 3D printing technologies in a move that aims to transform naval shipbuilding in the U.S.Huntington Ingalls’ Newport News Shipbuilding division will work with 3D Systems to develop additive manufacturing technologies expected to accelerate the adoption of metal 3D printing for building components of U.S. warships.The joint effort, which comes amid a significant technological transformation underway at Newport News…

Japanese Shipyards Ink Cooperation Agreement

Japanese shipbuilders Mitsui E&S Shipbuilding Co., Ltd. (MES) and Tsuneishi Shipbuilding Co., Ltd. announced they have signed a business cooperation agreement to partner in areas of commercial shipbuilding.The compatriot shipbuilders had announced in February 2018 they were discussing plans to partner, becoming the latest in a string of Japanese yards to team up to combat the industry downturn.Now, after several months of dialog, MES and Tsuneishi have identified specific areas for collaboration.

US Coast Guard Evaluating 3-D Printing

For the average person, tracking down a spare part is often merely an annoyance. But for the crew of a Coast Guard cutter, the availability of spare parts can be important to mission completion or greatly affect their work environment. The Coast Guard Research and Development Center in New London, Conn., is currently studying how the use of 3-D printing technology might improve mission readiness through logistical support. Now in the evaluation phase, 3-D printers are available…

ABS Pleased with Innovative Metals & Materials Award

In response to today's announcement by U.S. President Barack Obama regarding the awarding of funding under the Lightweight and Modern Metals Manufacturing Innovation Institute (LM3I) initiative to the American Lightweight Materials Manufacturing Innovation Institute (ALMMII), ABS Chairman and CEO Christopher J. ABS is consistently focused on identifying novel and innovative concepts that aid the marine and offshore industries in improving the design, construction and maintenance of their assets. The institute is a natural avenue to leverage ongoing ABS technology development in next-generation materials, metals and joining technologies. We are proud to be members of ALMMII and are thankful for the trust placed upon the team by the U.S. government.

World's Longest Wind Turbine Blades Development Project

UK's Energy Technologies Institute (ETI) appoints Blade Dynamics to develop technologies for constructing ultra long-length wind turbine blades. Blade Dynamics will construct blades for the ETI of between 80 to 100 metres in length, incorporating carbon fibre rather than conventional fibre glass. This compares with blades now deployed offshore of between 60 to 75 metres in length. The intended end use for the blade technology is on the next generation of large offshore wind turbines currently under development with a capacity of 8 to10MW.

SCRA-Led Shipbuilding Program Awarded $1.7m

SCRA announced a contract award totaling $1.7 million for the Shipbuilding Center of Excellence. The Center, known as the Center for Naval Shipbuilding Technology (CNST), is a Navy ManTech Center of Excellence, chartered by the Office of Naval Research (ONR) to develop advanced manufacturing technologies and deploy them in U.S. shipyards. CNST is managed and operated by SCRA affiliate ATI (Advance Technology International). The initial, two-year contract was awarded in August of 2009 and allowed for three follow-on, one-year extension options. The most recent award represents the first of the three potential option years and will be spent on Center operations and project development and management.

Wärtsilä Opens Manufacturing Technology Center

Wärtsilä has officially opens its Manufacturing Technology Centre (MTC) in Vaasa, Finland. The MTC is a new concept for Wärtsilä, and is aimed at securing and further developing its manufacturing competencies, and sharing manufacturing know-how throughout the global Wärtsilä network. The MTC concept is designed to enhance Wärtsilä's ability to effectively develop and globally share its core manufacturing competencies, including machining, forging, casting, welding, production & assembly automation, and digital manufacturing technologies. This will produce value-adding benefits by supporting component design, and manufacturing and supplier development. It will also optimize Wärtsilä's efforts towards "first time right" quality, "as promised" delivery times, and competitive costs.

GE to Build Plant for Batteries

The new battery business will be a part of GE Transportation and will serve customers in the rail, marine, mining, telecommunications and utility sectors. GE has invested more than $150m to develop advanced battery technologies, including a high energy-density sodium-based chemistry battery that will provide energy storage for a variety applications, including GE Transportation’s ecomaginationSM certified Evolution Hybrid Locomotive, mining truck drive system and tugboat electrification. In addition, GE has launch customers in several industries, including mining, telecommunications and utility, with key applications for heavy service vehicles, backup storage and load leveling for the smart grid.

'Waterfront Academy' To Teach Students About Shipbuilding

National Steel and Shipbuilding Company (NASSCO) and the Sweetwater Union High School District announced the creation of a "Waterfront Academy" that will train high school seniors in ship manufacturing technologies beginning in the next school year. This innovative program is expected to bring 60 to 75 incoming seniors to NASSCO's bayfront shipbuilding facility for both academic classes and career preparation. During a six-hour school day in classrooms currently under construction at NASSCO, students will receive hands-on training from the company's industry experts and will study academics with their Sweetwater teachers. Training and mentoring will be offered in trades such as electrical, machinery, pipefitting, sheet metal, ship fitting, rigging, and welding.

Liberty 129 Fast Ferry Tow Tank Test Scheduled

Bristol Harbor Marine Design (BHMD), a division of Bristol Harbor Group, Inc., has completed the hull and preliminary engineering for the Liberty 129TM, a new fast ferry that will compete with the foreign designs currently being constructed by US ship builders. A scale model of the hull has been constructed and tow tank testing is scheduled for October at the University of Michigan. The new design will be rolled out at the International Work Boat Show 4-6 December, in New Orleans. The design is all-American from the keel up to U.S. Coast Guard Sub-Chapter K regulations for medium to large size passenger vessels. Structural design and engineering are to the requirements of the American Bureau of Shipping Guide for Building and Classing High-Speed Craft.