ClassNK Approves Minimal Ballast Water VLCC Design

Leading classification society ClassNK announced that it has granted AIP (Approval in Principle) to the MIBS (Minimal Ballast Water Ship) VLCC design developed by Namura Shipbuilding Co., Ltd. in cooperation with the Shipbuilding Research Centre of Japan.

Although the IMO’s Ballast Water Management Convention has yet to enter into force, installation of ballast water treatment systems are already presenting owners with both financial and technical challenges. Namura’s new MIBS VLCC design, addresses the challenges via the use of a revolutionary new hull form, which greatly reduces the amount of ballast water necessary for safe operations. The MIBS design reduces the weight of ballast water required in normal ballast conditions by around 65%, paving the way for the use of smaller ballast water treatment systems and reducing fuel consumption.

This new MIBS design builds on a previous Non-Ballast Water Ship (NOBS) design project promoted by the Japan Ship Technology Research Association as part of a Japanese national project under the initiative of Ministry of Land, Infrastructure and Transport and supported by Japan Railway Construction, Transport and Technology Agency and The Nippon Foundation, and further developed by Mitsubishi Heavy Industries, IHI Marine United (now Japan Marine United), Shipbuilding Research Centre of Japan and ClassNK.

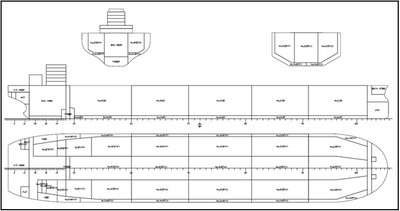

While the NOBS project succeeded in creating tanker designs which could operate without the need for ballast water, the extremely wide hull shape limited its commercial applications. The MIBS design however, incorporates features from the NOBS design with a flatter bottom and standard breadth hull. This allows for a dramatic reduction in the amount of ballast water needed, while maintaining the dimensions of a standard VLCC.

Speaking on the occasion, ClassNK Chairman and President Noboru Ueda said: “Ballast water management is a major challenge for the maritime industry, and that is why ClassNK is constantly working with the industry to find new practical solutions, such as the use of 3D scanners for BWMS retrofits as well as BWMS containerization. Namura Shipbuilding’s new MIBS design offers shipowners with another new practical solution. One that not only represents a massive technological leap in terms of ship design, but will also help reduce ballast water management costs for shipowners. MIBS is truly an impressive technical achievement.”

AIP is an essential step in the process of bringing novel concept designs into practical use. As part of the AIP process, ClassNK carried out a thorough review of the MIBS plans and verified the results of numerous performance tests. The AIP certifies that the revolutionary hull design satisfies all international requirements for hull strength and safety, the same as more traditional tanker hull designs.