In 2011, Naval Architecture and Marine Engineering firm Guido Perla & Associates, Inc. (GPA) signed a contract with Brazilian shipyard EISA. Estaleiro Ilha for two GPA 675 PSV designed specifically to Petrobras requirements (PSV 3000). Both vessels are currently under construction at EISA for the Brazilian offshore operator Astromaritima Navegacao S/A.

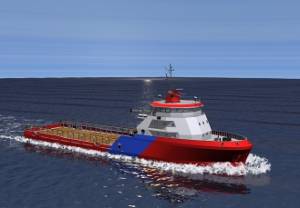

The vessels are outfitted with a diesel-electric propulsion system comprised of equipment by Berg Propulsion and Caterpillar. The system consists of two azimuthing drives, each rated for 2,500kW and two bow thrusters, each rated for 750kW. The propulsors, bow thrusters and other electrical consumers will run on four Caterpillar generators each rated for 1,825kW and an emergency generator rated for 190kW. The electrical components of the propulsion system will be provided by WEG. The GPA 675 PSV has an overall length of 76.80 meters, a beam of 19.00 meters, and a maximum draft of 6.00 meters.

The use of a diesel-electric propulsion system creates valuable flexibilities, allowing for the maximization of cargo carrying capacities below deck, as the engine room is located above the main deck, a concept pioneered by GPA several years ago. The cargo tank equipment will be supplied by Van Aalst Marine & Offshore.

The GPA 675 PSV, providing accommodations for 22 crew members and passengers, will bear the class notation ABS, +A1, Offshore Support Vessel, +AMS, +DPS-2, Circle E and +ES. These vessels year are under an 8-year contract for Petrobras, operating in the Campos Basin fields in Brasil.

To offer a cost-effective solution to the rapidly growing and highly competitive Brazilian market, GPA’s designs are based on well-proven, single-curvature hullforms and other construction methods simplifying the building process, such as flanged plate framing and transverse framing. GPA has had great success with these methods that have become the standard not just for offshore designs but for most vessel types GPA designs.

In recent years, GPA extensively focused on building relationships with local operators and shipyards in Latin America and created a direct presence with subsidiaries in Chile and Brazil. These subsidiaries execute multiple functions, which encompass providing naval architecture support to the GPA headquarters in Seattle, working in conjunction with the GPA design and engineering staff, as well as providing technical assistance, and Project and Contract Management directly to local shipyards, such as EISA, that are currently constructing GPA designs. These activities reinforce GPA’s approach of direct communication and close working relationships throughout the development and construction process.

“The local market has been developing very attractive projects that we want to take part in, and therefore, we need to be prepared to support and serve our clients during the complete execution of the projects,” says Paulina Alvarez, Business Manager of Guido Perla Latin America in Chile (GPLA). “A local presence facilitates keeping a close liaison with clients after launch and delivery with respect to the operation and maintenance of each vessel,” says Ms. Alvarez. “One of our main assets and differentiation points is that GPA has always developed special solutions that suit each client’s needs, therefore it is of advantage for us to be closer and more accessible to our clients in order to get a better understanding of their situation, needs and requirements.”