Eniram Ltd., a provider of energy management technology and analytic services to the shipping industry, announced at Gastech the release of Eniram Engine, a new tool to help guide TFDE LNG carriers' engineers and officers efficient use of engines and fuel.

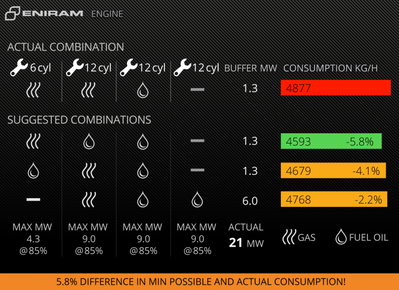

High engine efficiency is imperative to achieve low specific fuel consumption (SFC) and cost savings. Eniram Engine takes into account real-time engine operation by combining data from onboard fuel flow meters with generator loads, power produced and SFC. Analyzing the data, Eniram Engine then suggests engine combination and fuel type for the prevailing conditions to save fuel.

According to its developers, Eniram Engine understands the different operating modes of LNG carriers. When fuel oil is used to supplement boil-off gas (BOG) as a fuel for the ship’s propulsion and energy systems, Eniram Engine will provide guidance only with this mixed fuel usage. Additionally, if the carrier is equipped with a reliquefication plant and the BOG is reliquefied and fuel oil is used for the engines, then only suggestions for fuel oil usage are provided.

In addition, Eniram Engine’s buffer feature helps engineers understand how much operating reserve power (or buffer) they have available for each engine suggestion compared to the actual, in case there is a sudden need to increase power output.

“Monitoring the available power is critical for safe and efficient operations on board. Eniram Engine demonstrates that even small changes in engine use pattern during a voyage can have a significant impact in reducing fuel and overall operating costs,” said Eniram CTO Jussi Pyörre. “Based on our analysis, shipowners will be able to achieve a reduction of 2 to 4 percent of total fuel consumption.”