C-Job CEO Basjan Faber was Born to Design

Born and raised on the water by entrepreneurial parents, Basjan Faber knew from a young age that his future and fate was in maritime, specifically ship design. Today the CEO leads a vibrant, diverse and fast-growing naval architecture firm that he co-founded with partners in 2007. Headquartered in Amsterdam, C-Job has a unique approach to its business and is expanding its international footprint, as Maritime Reporter & Engineering News discovered when we visited with him in The Netherlands last month.

“I have always been inspired by ships, and I knew by the end of grammar school that I wanted to be a naval architect. In fact, I remember going with my parents to a university to explore naval architecture at the age of 11, and I’m sure the professors at that time were thinking ‘what is this young boy doing here,’” said Basjan Faber, co-founder and CEO of C-Job.

But Faber did indeed know his place and his heading, and in 2007 he and two partners founded C-Job, which today is a growing force in the world of maritime design, evolving from a trio 12 years ago to more than 160 employees worldwide today. Most recently it opened an office in Houston, Texas, a move that Faber sees as a stepping stone to growing his business in the Americas, with an eye on Asia and Australia in the future. “But we can’t do everything at once,” said Faber.

The Man, The Plan

Faber grew up on the water, on boats personally and professionally as his parents were entrepreneurs, owning their own inland cargo vessel operation, and when not working the family could be found sailing.

“I know it’s cliche, but it all starts with your own parents. They gave me a kick-start, direction and they were entrepreneurs,” said Faber in assessing how he came to love the maritime business. “Other than that, I really don’t have one specific mentor. In general, I am very open and receptive to ideas, I’m a good listener, and I like to learn from others and take different ideas to help form future direction.”

Per his 11-year-old career ambitions, Faber graduated with a Bachelor’s degree in Naval Architecture in 2002. But at the time, the maritime business in The Netherlands was in a slump. Realizing his ambition to be an entrepreneur, he opted to get his Master’s degree – a “technology management MBA” – before entering the workforce full-time with another naval architecture firm.

But the young man with the big dreams could not be confined under the employ of another, so Faber and two classmates ventured to create C-Job, opening shop officially in December 2007.

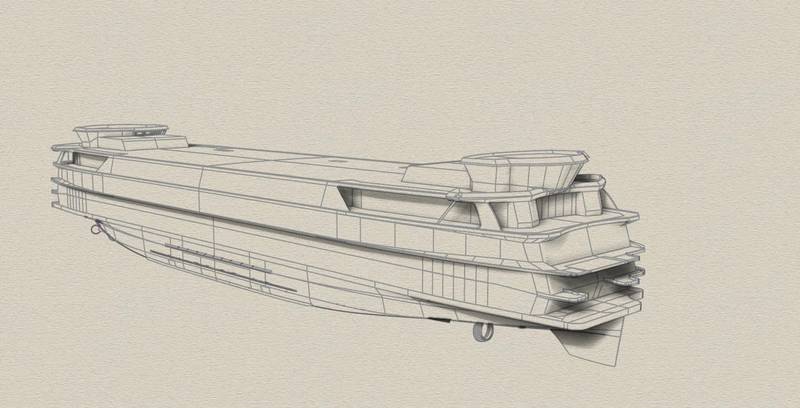

From the outset, the C-Job founders had a plan to grow substantially and internationally. When Faber and his partners started C-Job, their mandate was not centered on the design of a certain type of vessel or market segment, rather they saw an opportunity to focus on the client and their needs as well as change the process and approach of how a design comes together (more efficiently); ships and boats that were purpose designed and built in tandem with the customer. “From the beginning we were thinking about how we can do things differently,” said Faber. “The maritime industry is rather traditional with many family owned and long-existing businesses, and we simply said ‘we think we can do better and bring it to the next level.’” C-Job Naval Architects Offshore Wind Installation Vessel ‘Orion’ Render. Photos: C-JobThe C-Job DNA

C-Job Naval Architects Offshore Wind Installation Vessel ‘Orion’ Render. Photos: C-JobThe C-Job DNA

One of the biggest differentiators in the C-Job model is the fact that, when a project is developed and delivered, it is the client, not C-Job, that owns the intellectual property of the final design. “We don’t have a library of common solutions and vessels, we work closely with our clients to co-create our designs,” said Faber. While he admits that “this is completely different than what is traditional,” he said the business model demands mutual trust among all parties, and is popular with C-Job clients and prospects. “The most important attributes of C-Job (to our clients) is that we are an independent office, we’re a knowledgeable, innovative and we have a passionate team.”

While nearly every corporate leader will insist that ‘the team’ is the cornerstone of success, in Faber’s case the statement is genuine.

“We are not managed from the top down,” is how Faber easily describes his company, explaining that the DNA and culture of C-Job is one that inspires free-thinking and entrepreneurship, much like he learned from is parents. “We give a lot of responsibility to our team to talk to the industry, develop their skills and to help develop new solutions.”

To that end, in the never-ending quest for technical talent, C-Job is not looking merely to hire employees, it is constantly on the search for innovative individuals that are ready, able and enabled to develop and create solutions on their own, seeking and delivering business opportunities to the company.

The C-Job DNA flows beyond the company walls and throughout industry, as Faber is an ardent supporter of collaboration to foster strength and growth. “You can achieve more by collaboration. If you’re throwing up fences to protect yourself, I don’t think it gives you the best future,” said Faber. “We believe in open source so outsiders can help to optimize the solutions. But there must be some caution, too, as this is idealistic. We need to have a return on investment, and we can’t have people simply taking our ideas and making them their own.”

The key in Faber’s reckoning is trust, as he seeks insight from anywhere he can find it, including potential competitors. An example of this is a Memorandum of Understanding signed in November 2018 with Glosten. “In Glosten we found a partner with mutual trust and chemistry and an atmosphere of collaboration,” said Faber. “The main focus of our collaboration is to prepare for the offshore wind energy business in the U.S.”

The Path Ahead

The maritime industry is in the midst of transcendent transformation, as a host of increasingly stringent emission regulations coupled with the accelerating advance of technology in general, digitalization in particular, is literally changing the look and performance of ships and boats at sea. Faber said that C-Job is increasingly engaged in Research and Development projects, with an eye on where the industry will be moving in the next 10 to 20 years. He said the investment is valuable on a number of levels, least of not which is developing future technology to raise not only his business, but the industry as a whole. “Perhaps most importantly, it inspires our team and inspires the atmosphere for new hires; they see that you are investing in the company and the future.”

© 2019 Martijn Gijsbertsen / Marco Vet

© 2019 Martijn Gijsbertsen / Marco Vet

While the opening of the Houston office was a strategic point for the company in an opening of the Americas in general, the physical opening was the culmination of working in the market for years, getting to know the client base, the projects and the opportunities.

“We have been building our business and contacts in the U.S. for three years,” said Faber. “One of the focus markets we have here (in the Netherlands) is dredging, so that’s where we started. But the opportunities in the U.S., and throughout the Americas, go far beyond dredging. There is offshore wind, the cruise and ferry industries, and super yachts. The Houston office is simply a spin-off of all the business that we already have in the U.S. It’s logical to make that step.” While expansion in the U.S. was a logical one, Faber assures us “it will not be the last!”

While the need for emission reduction solutions gains steam throughout the maritime world, Faber and C-Job were pioneers. “When we started the business in 2007, there were no projects for LNG (as a fuel), for example. Things have quickly changed with pressure to lower emissions. Since 2011/12, LNG became a hot topic, and nowadays in every project, LNG is considered or applied.” (See sidebar on the Texelstroom ferry project on page 38).

Though LNG is growing in popularity, C-Job sees it as a transition fuel, and is investing research dollars in the future tech and fuels that will power maritime’s future. “Our R&D efforts are focused on how we will do things in 10 years, 20 years from now. For example we’ve just finished a study on the application of ammonia as a future fuel,” said Faber. He, like most, agree that there is no single ‘silver bullet’ to answer the decarbonization challenge, rather a mix of technologies including fuel, battery tech and innovations in sail and renewable energies. “We’ve done a study on the implication of Rotor Sails (wind power), which is an easy-to-use solution, but it’s very route specific, it’s not for every vessel. In the Baltic and certain Atlantic routes it is very applicable. The use of the Rotor Sails goes hand in hand with better route planning to optimize.”

Optimizing the route is what Basjan Faber and his growing team do best, navigating the ups and downs, ins and outs of the ever-changing maritime landscape. But today the young, confident CEO has his hand on the throttle and it’s ‘Full Steam Ahead.’

Design Project Report: TESO’s Ferry Texelstroom

With C-Job’s broad portfolio of vessel design projects, one might assume that Basjan Faber, CEO, would have difficulty selecting just one that best embodies the capability of his company. But when asked the question the answer was quick and sure: TESO’s Texelstroom Ferry Project. “It was a vessel with technology ahead of its time,” Faber said. The ferry is operated by locally owned organization TESO, and Texelstroom was designed five years ago and built three years ago. C-Job was responsible for the Initial, Concept & Basic Design for the double-ended ferry which has been in operation since 2016 between the Dutch island of Texel and Den Helder. When the project started in 2014, the initial thought was to use LNG, but at the time the fueling infrastructure was not well developed. But in the Netherlands the use of Compressed Natural Gas (CNG) is common for vehicles and buildings, providing an abundant fueling infrastructure capability. The only problem: CNG was not approved yet for maritime use.

“It took many meetings and close cooperation with class (Lloyd’s Register) throughout the project, but we made it happen,” said Faber.

Eventually, TESO decided on a “Dual Fuel System” with CNG. Furthermore, there is a Hybrid propulsion system with Battery Packs to shave of the peaks in energy demand on board. Solar panels are responsible for about one half of the hotel function.

C-Job performed many more studies and consultancy tasks like: Windflow/CFD Analyses, hull shape optimization, Intelligent Ventilation study, FEM Analysis, Stability calculations, and much more. Also, C-Job assisted TESO during the build of this vessel at LaNaval Shipyard in Spain. TESO’s Ferry Texelstroom. Image Courtesy C-Job

TESO’s Ferry Texelstroom. Image Courtesy C-Job

This was published in the October 2019 edition of Maritime Reporter & Engineering News. https://magazines.marinelink.com/nwm/MaritimeReporter/201910/