General Dynamics NASSCO and Braemar LNG BV announce LNG containment technology licensing agreement

General Dynamics NASSCO and Braemar LNG BV, a wholly owned subsidiary of Braemar Shipping Services PLC, have signed a technology licensing agreement for Braemar to use NASSCO’s intellectual property in its design and construction of Flat-Panel, Semi-Membrane, Prismatic-Shaped (FSP) LNG containment systems.

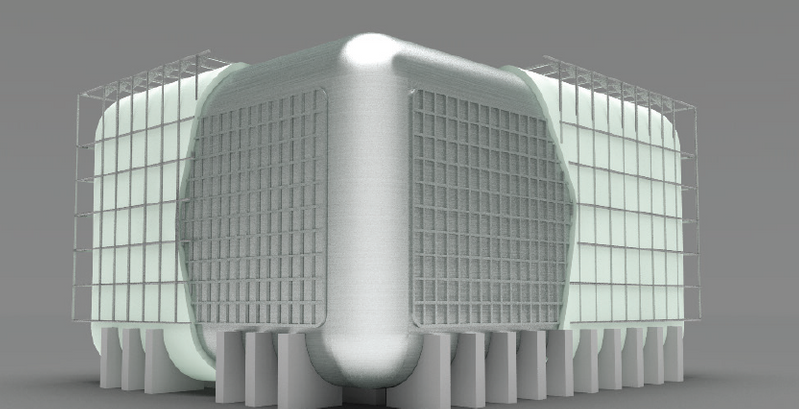

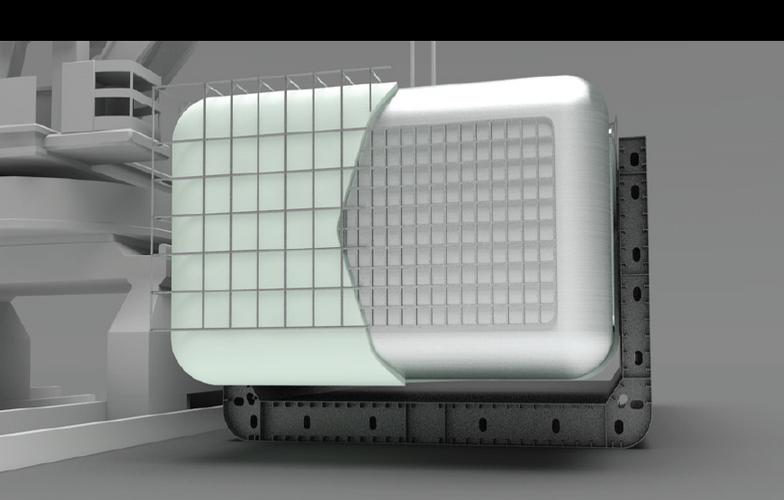

FSP is a new multipurpose Type B flat-panel, semi-membrane, prismatic-shaped LNG tank-containment system which uses flat plate technology and a universal joint configuration. The system is constructed, outfitted, insulated and fully tested off hull and lifted complete into a vessel while the vessel is still under construction. It is designed to avoid any issues associated with partially filled membrane-type tanks. This off-hull fabrication leads to a significant reduction in vessel construction time and improves the accuracy, reliability and tank-to-tank construction learning.

“We are very excited about licensing this innovative LNG containment technology to Braemar. FSP can be used in multiple LNG applications, including transportation, marine fuel tanks, bunker barges and floating offshore applications,” said Kevin Graney, vice president and general manager of General Dynamics NASSCO.

The agreement is the culmination of years of development work undertaken by the two parties, and Braemar is seeing strong potential demand from the marketplace.

“We are delighted that this key stage in the FSP project has now been reached,” says Geoff Green, Managing Director of Braemar Engineering. “The industry is asking not if, but when, FSP will come to market, and I am pleased to now be in a position to deliver a positive response.

The new Type B containment system is designed to be constructed, outfitted, insulated and tested off hull and lifted complete into the vessel while the vessel is still in the construction dock. This leads to a significant reduction in vessel construction time and at the same time the use of on shore construction facilities ensures the highest standards of quality care and repeatability.

Approval in Principle was obtained from Lloyds Register (LR) and the American Bureau of Shipping (ABS).